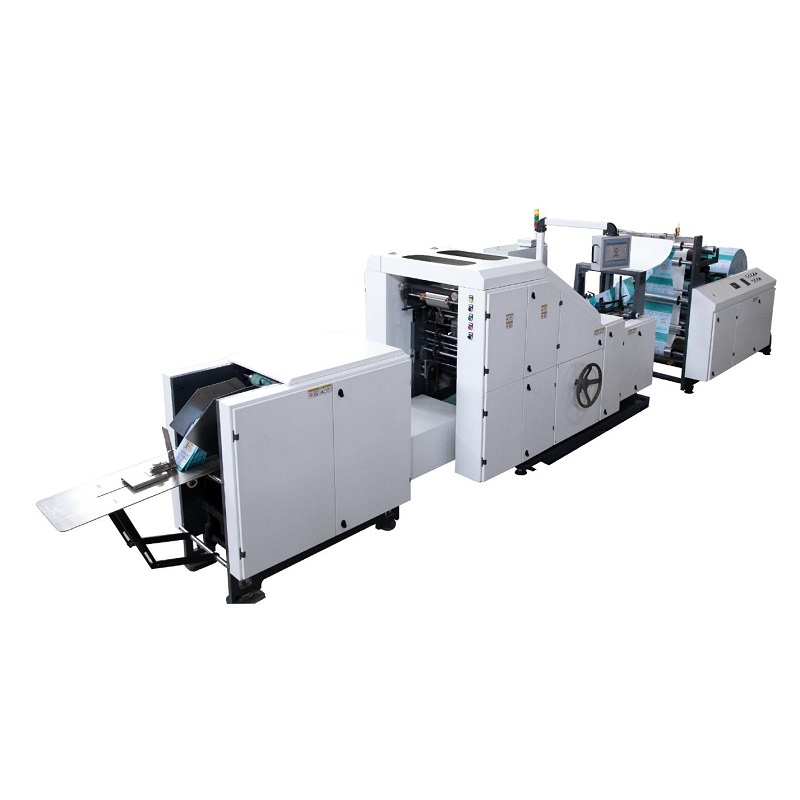

2021 High quality Flatbed Die-Cutting Machine - GW double station die-cutting and foil stamping machine – Eureka

2021 High quality Flatbed Die-Cutting Machine - GW double station die-cutting and foil stamping machine – Eureka Detail:

S series Double Unit Machine can achieves foil stamping, embossing, die cutting, stripping and automatic delivery process in one pass. Flexible combine methods according to different product’s requirements. The productivity is 3 to 4 times of normal die cutting and foil stamping machine. Two platen press sections working at 5000 sheets per hours with 1060mm sheet size which can bring higher productivity and lower cost to your company. This machine can run card paper with 90-2000 g/m2. The high accurate operation can provide high efficiency working process. This machine is your best choice for foil stamping and die cutting multi-process production. S Series Double Unit machine can reduced labor intensity. Multiple optional configuration can adapt to your various production requirements.

1.S 106 DYY :

1st Unit: High pressure Embossing and 3 Longitudinal foil shaft

2nd Unit: 3 Longitudinal foil shaft

2.S 106 YQ:

1st Unit: 3 Longitudinal foil shaft and 2 transversal foil shaft

2nd Unit: Die-cutting and stripping

3.S 106 YY:

1st Unit: 3 Longitudinal foil shaft and 2 transversal foil shaft

2nd Unit: 3 Longitudinal foil shaft

More customized configuration can be combined according to customer’s demand.

| Model | S 106 DYY |

| Sheet size | (Max)1060X760mm |

| (Min) 450X370mm | |

| Max. Die-cutting size | (Max)1045X745mm |

| Max. Stamping size | (Max) 1040X740mm |

| Max. Die-cutting speed | (Max) 5500(S/H) |

| Max. Stamping speed | (Max) 5000 (S/H) |

| Max. Hologram Stamping Speed | (Max) 4500 (S/H) |

| Card Board | (Min)90—2000g/m2 card board, 0.1—3mm |

| Corrugated Board (only in die-cutting) | ≤4mm, E、B flute |

| Max. Embossing pressure (1st unit of S 106 DYY) | 500 Ton |

| Max. Stamping pressure (2nd unit of S 106 DYY) | 350 Ton |

| Heating zone | 20 Heating zones, temp. 20℃–180℃ |

| Adjustable gripper margin | 7-17mm |

| Feeder pile height | (Max)1600mm |

| Delivery pile height | (Max)1350mm |

| Main motor power | 22KW |

| Total power | 56KW |

| Total weight | 42 Tons |

FEEDING UNIT

-Non-stop feeding with automatic pile lift and pre-pile device. Max pile height 1600mm

-High quality feeder head with 4 sucker and 4 forwarder to assure stable and fast feeding for various of materials

-Front control panel for easy operation

-Anti-static device*option

TRANSFER UNIT

-Mechanical double sheet device for cardboard, supersonic double sheet detector for paper *option

-Pull and push side lay suitable for thin paper and thick cardboard, corrugated

-Paper speed reducer to make smooth transfer and precise positioning.

DIE-CUTTING AND HOT FOIL STAMPING UNIT

-Die-cutting pressure controlled by YASAKAWA Servo System Max. 300T *R130/R130Q can up to 450T

-Pneumatic quick lock upper&lower chase

- Centerline system on die-cutting chase with transversal micro adjustment ensures accurate registration that result in quick job changeover.

STRIPPING UNIT

-Standard 3 longitudinal and 2 transversal unwinding shaft can run at same time , each driven by independent Yasakawa servo motor, with foil length alarm.

-Precise hologram system *option for each shaft

SMART HUMAN MACHINE INTERFACE (HMI)

-15″ and 10.4″ touch screen at feeder and delivery section for easy control of machine at different position, all settings and function can be easily set through this monitor.

-15″ independent monitor for foil stamping control, calculate and suggest the best pulling/stepping way for different pattern, can reduce foil waste by 50%

-Heating timer to reduce waiting time*Option

DELIVERY UNIT

- Non-stop delivery with automatic pile lowering

- 10.4″ monitor

- Automatic non-stop delivery rack*only on R130Y

- Anti-static device*option

- Tap inserter*option

Feeding Unit

High quality feeder made in Taiwan with 4 suckers for lifting paper and 4 suckers for forwarding paper ensure stable and fast feeding paper. The height and angle of suckers are easily adjustable to keep sheets absolutely straight.

Mechanical double-sheet detector, sheet-retarding device, adjustable air blower ensure sheets transfer to the belt table steadily and precisely.

Vacuum pump is from German Becker.

Pre-piling device makes non-stop feeding with high pile (Max. pile height is up to 1600mm).

Perfect piles can be formed on pallets which run on rails for pre-piling. This makes a significant contribution to smooth production and let operator move the prepared pile to feeder accurately and conveniently.

Single position engagement pneumatic operated mechanical clutch insures the first sheet after every re-start of machine is always fed to front lays for easy, time-saving and material-saving make-ready.

The side lays can be switched directly between pull and push mode on both sides of the machine simply by turning a bolt without having to add or remove parts. This provides the flexibility for processing a wide range of material: irrespective of whether the register marks are to the left or right of the sheet.

Side and front lays are with precision optical sensors, which can detect dark color and plastic sheet. The sensitivity is adjustable.

Operation panel for feeding part is easier to control the feeding process with LED display.

Separate drive controls for main pile and auxiliary pile

PLC and electronic cam for timing control

Anti-obstacle device can avoid the machine damage.

Japan Nitta convey belt for feeder and the speed is adjustable

Foil stamping and Embossing Unit (* Embossing function for S 106 DYY Model)

The mechanical units are redesigned by the specialists from Germany and Japan that enable the working pressure to reach 550 tons for better quality of foil stamping and embossing with higher speed as well. (* Embossing function for S 106 DYY Model)

Individually controlled programmable foil pull rollers ( 3 sets in longitudinal and 2 sets in transversal direction) driven by YASKAWA servo motors

Longitudinal full format foil feeding system for stamping in 2 direction at the same time which helps greatly in saving foils as well as the time to change foils.

20 individually controlled heating zones , using intubation heating system ,with a tolerance within ±1C

1 set of ductile iron honeycomb chase and locking device for dies

Dwell time device for big area stamping

2 direction air blowing separation device

The brush system removes used foil from the side of the machine, where it can be collected and disposed of.

Optical sensors detect foil breaks.

Optional foil rewinder WFR-280 to dispose of used foil, enable foils to be wound onto six independent shafts in a dedicated module.

Die-cutting Unit

Pneumatic lock system makes easier lock-up and release of cutting chase and cutting plate.

Pneumatic lifting cutting plate for easy slide in and out.

Centerline system on die-cutting chase with transversal micro adjustment ensures accurate registration that result in quick job changeover.

Accurate positioning of Cutting chase controlled by precision optical sensors with automatic check-lock device

Cutting chase turnover device

Siemens main motor controlled by Schneider inverter.

Micro-adjustment of cutting force (pressure accuracy can be up to 0.01mm, Max. die-cutting pressure can be up to 300 tons) by worm gear driven by servo motor and controlled easily by 15 inch touch screen.

High quality gripper bar from Japan with long life

Uniquely designed gripper bar need no spacer for compensation to insure accurate paper registration

Cutting plates of different thickness(1pc of 1mm, 1 pc of 3mm, 1 pc of 4mm) for easy job-changing

High quality Renold chain from England with pre-extended treatment ensures stability and accuracy in long run.

High pressure index drive system for gripper bar positioning control

Overload protection device with torque limiter creates the highest level of security for operator and machine.

Automatic lubrication and cooling system for main drive and automatic lubrication for main chain.

Stripping Unit (* Stripping function for S 106 YQ Model)

Centerline registering ensures fast installation of the middle stripping frame; it also shortens set-up time while changing jobs.

You can choose to use stripping function by raising or lowering the upper stripping frame manually.

All stripping tool manufacturing is standardized that they are applicable to machines of different make

Up, middle and down stripping frame driven by independent cam.

Delivery Unit

Delivery pile height is up to 1350mm.

Photoelectric devices preventing over-ascending and over-descending of delivery paper pile

Pile can be counted by optical sensor (standard) and the unit can be integrated with a device for inserting paper slips into the pile (optional). It will facilitate to take off blanks and pack them into cases.

The whole machine can be adjusted by 10.4 inch touch monitor in rear side

Auxiliary delivery rack is configured for non-stop delivery.

Electric Parts

Electronic detectors, micro switched and photoelectric cells controlled by PLC on entire machine

Electronic cam switch and encoder

All the major operation can be done by 15 and 10.4 inch touch monitor.

PILZ safety relay as standard ensure highest safety standard.

Internal inter-lock switch fulfill CE requirement.

Applies electric parts including Moeller, Omron, Schneider relay, AC contactor and air breaker to assure stability in long run.

Automatic fault display and self-diagnose.

| Part Name | Brand | Country of Origin | Remark |

| Bearing | NSK | Japan | |

| Bearing | SKF | Swiss | |

| Elec-magnet valve and pneumatic components | SMC/FESTO | Japan | |

| Index box | Taiwan | ||

| Monitor | Sharp | Japan | |

| Gripper | Japan | ||

| Main Gripper Chain | Renold | U.K. | |

| Vacuum pump | Becker | German | |

| Index box | Taiwan | ||

| Die-cutting frame | China | Integrated molding | |

| 20 individual controlled heating zone | German | Heating tube | |

| Servo motor for foil roller | Yaskawa | Japan | |

| Transmission chain | Japan | ||

| Feeder | Taiwan | ||

| Main motor inverter | Schneider | German | |

| Main motor | Siemens | German | |

| Convey belt | Nitta | Japan | |

| Button and electrical components | Eton | German | |

| Hydraulic sealing ring | German | ||

| Torque limiter | Taiwan | ||

| Air breaker, contactor and joint | Schneider, Eton, Moeller | German | |

| Safety relay | PILZ | German | |

| Electronic horn | Patlite | Japan | |

| Crank shafts | China | 40 Cr harden Heat Treatment | |

| Worm rod | China | 40 Cr harden Heat Treatment | |

| Worm Gear | China | Copper | |

| HMI system | 19 inch AUO10.4 inch Sharp |

Feeder/delivery area static eliminator

Chase changer

WFR280 automatic foil rewinder

Compact foil rewinder

Product detail pictures:

Related Product Guide:

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and advancement, we'll build a prosperous future together with your esteemed organization for 2021 High quality Flatbed Die-Cutting Machine - GW double station die-cutting and foil stamping machine – Eureka , The product will supply to all over the world, such as: Sydney, Latvia, India, Our products have won an excellent reputation at each of the related nations. Because the establishment of our firm. we have insisted on our production procedure innovation together with the most recent modern day managing method, attracting a sizable quantity of talents within this industry. We regard the solution good quality as our most vital essence character.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.