2021 High quality Flatbed Foil Stamping Machine - Automatic Foil-stamping & Die-cutting Machine TL780 – Eureka

2021 High quality Flatbed Foil Stamping Machine - Automatic Foil-stamping & Die-cutting Machine TL780 – Eureka Detail:

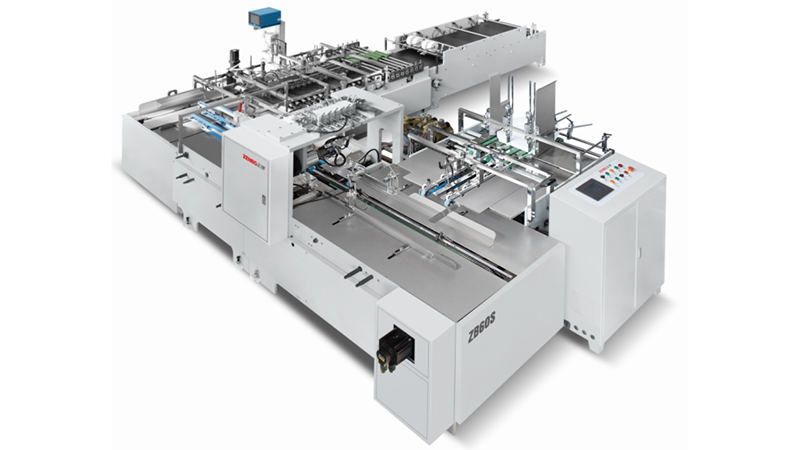

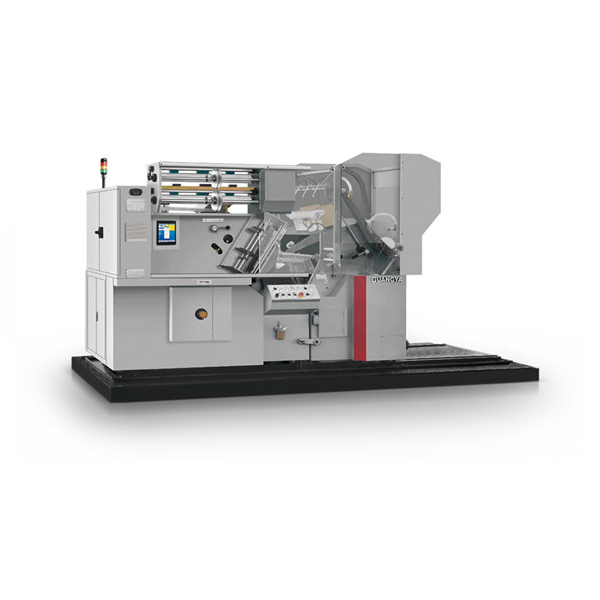

TL780 automatic hot stamping and die-cutting machine is a new generation product developed by our company after years of experience in the production. TL780 is designed to meet today’s hot stamping, die-cutting, embossing and creasing processes. It is used for paper and plastic film. It can automatically complete the working cycle of paper feeding, die-cutting, peeling and rewinding. TL780 is composed of four parts: main machine, hot stamping, automatic paper feeding, and electrical. The main drive is by the crankshaft connecting rod mechanism drives the press frame to reciprocate, and the pressure adjusting mechanism jointly completes the hot stamping or die cutting work. The electrical part of the TL780 is composed of main motor control, paper feeding/receiving control, electrochemical aluminum foil feeding control and other controls. The whole machine adopts microcomputer control and centralized lubrication.

Max. Sheet Size : 780 x 560mm

Min. Sheet Size : 280 x 220 mm

Max. Feeder Pile Height : 800mm Max. Delivery Pile Height : 160mm Max. Working Pressure : 110 T Power supply: 220V, 3 phase, 60 Hz

Air pump displacement: 40 ㎡/h Paper range: 100 ~ 2000 g/㎡

Max. Speed: 1500s/h paper <150g/㎡

2500s/h paper >150g/㎡Machine Weight: 4300kg

Machine Noise: <81db Electrothermal plate power: 8 kw

Machine Dimension: 2700 x 1820 x 2020mm

| TL780 Hot Foil Stamping and Die Cutting Machine | ||

| No. | Part Name | Origin |

| 1 | Touch screen multicolor | Taiwan |

| 2 | PLC | Japan Mitsubishi |

| 3 | Temperature Control:4 Zones | Japan Omron |

| 4 | Travel switch | France Schneider |

| 5 | Photoelectric switch | Japan Omron |

| 6 | Servo motor | Japan Panasonic |

| 7 | Transducer | Japan Panasonic |

| 8 | Automatic oil pump | USA Bijur joint venture |

| 9 | Contactor | Germany Siemens |

| 10 | Air switch | France Schneider |

| 11 | Safeguard Control:Door lock | France Schneider |

| 12 | Air clutch | Italy |

| 13 | Air pump | Germany Becker |

| 14 | Main Motor | China |

| 15 | Plate: 50HCR Steel | China |

| 16 | Cast: Anneal | China |

| 17 | Cast: Anneal | China |

| 18 | Honey Comb Board | Swiss Shanghai joint venture |

| 19 | Adjustable Chase | China |

| 20 | Electric parts meet CE standard | |

| 21 | Electric wires meet CE standard | |

Product detail pictures:

Related Product Guide:

Our commission is always to provide our customers and clientele with best quality and aggressive portable digital products for 2021 High quality Flatbed Foil Stamping Machine - Automatic Foil-stamping & Die-cutting Machine TL780 – Eureka , The product will supply to all over the world, such as: Argentina, Canberra, Indonesia, Now, with the development of internet, and the trend of internationalization, we have decided to extend business to overseas market. With the propose of bringing more profits to oversea customers by providing directly abroad. So we have changed our mind, from home to abroad, hope to give our customers more profit, and looking forward to more chance to make business.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!