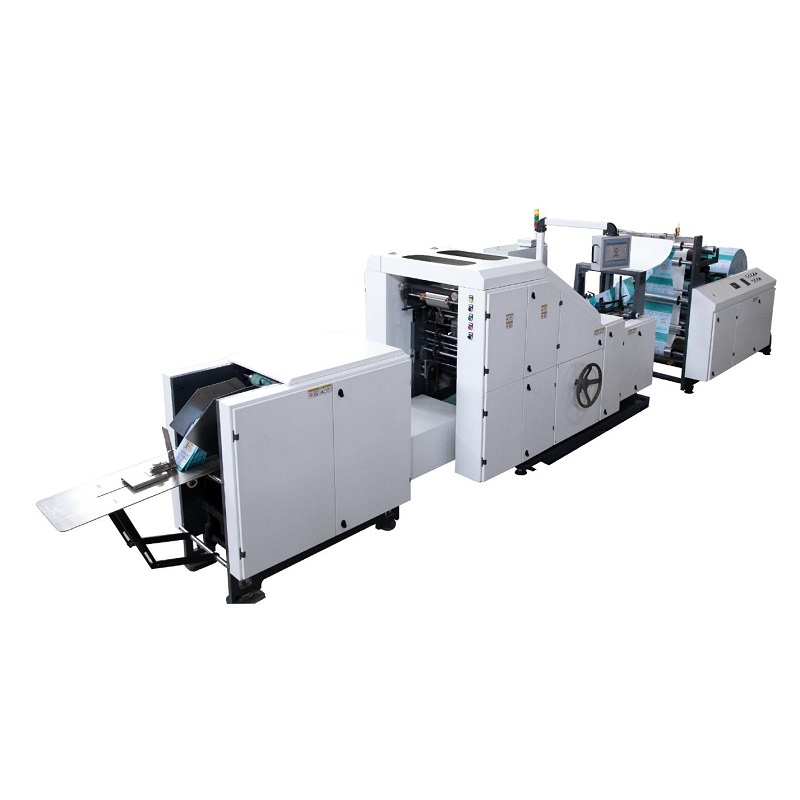

2021 Latest Design Paper Bag Punching Machine - High Speed Bag Making Machine SLZD—D600 for Plastic Composite Film – Eureka

2021 Latest Design Paper Bag Punching Machine - High Speed Bag Making Machine SLZD—D600 for Plastic Composite Film – Eureka Detail:

Machine function: Three-sided sealing, zippers, self-supporting bag-making machine.

Main electrical configuration:

Main electrical configuration with three traction servo motors/Panasonic PLC control system/Touch screen.

Main driver with AC motor with TAIAN converter/Temperature control 16 way/Unwinding Constant Tension.

Material: BOPP. COPP. PET. PVC. Nylon etc. Plastic Composite Film Multilayer Co-extrusion Film, Aluminum-plated Composite Film, Paper-plastic Composite Film and Pure Aluminum Foil Composite Film

Maximum Rhythm of Bag Making:180 pieces/min

Maximum discharge line speed: Within 40m/min(Depend on material)

Bag size: Length: 400 mm, exceeding this length by double feeding (maximum 6 times)

Maximum width: 600 mm

Max size for material:∮600×1250mm(Diameter x Width)

Number of heat sealing knives:

Longitudinal seal is heated /cooled up and down by four groups

Horizontal seals are heated up and down in three groups and cooled up and down in two group.

Zippers are heated in two groups.

Number of Thermoelectric Blocks:20Pieces

Range of Temperature:0-300℃

Power:65Kw(In practice, the power is about 38 Kw when the power is just turned on and about 15 Kw when the heat preservation is carried out.)

Dimension:L12500×W2500×H1870mm

Weight:7000KG

Control System: SSF-IV Composite Film High Speed Bag Making Machine

1.Unwind Unit

A.Structural form: Horizontal working position (composed of magnetic powder brake, air cylinder, swing roll, frequency converter, motor, traction roll sensor and control system)

B.Pneumatic locking device for discharging shaft and inflation shaft

2.Unwinding tension

A. Control mechanism: Composite constant speed tension system consisting of computer control, magnetic powder brake, frequency converter and AC motor, sensor and rotary encoder, cylinder to swing roll

B. Regulating Drive: PID regulating and PWM drive

C. Detection Mode: Integrated Detection of Sensor and Rotary Encoder

3.Correction systerm

Structure: Screw adjusts vertical lift of K-frame

Drive: Solid State Relay Drive Low Speed Synchronous Motor

Transmission:Coupling

Control Form: Computer Centralized Control with Dual Photoelectric Sensors

Detection Method: Reflective Photoelectric Sensor Detection

Tracking accuracy:≤0.5mm

Adjustment scope:150 mm

Range of Photoelectric Search:±5-50mm adjustable limit switch interval

4.Opposite side

Structure: adjustable cot center two-way rotary adjusting structure

Form: Manual adjustment (adjusting handwheel)

5.Upper and lower pairs of flowers

Structure: Upper and lower adjustment of single roller

Form: Manual adjustment (adjusting handle)

6.Longitudinal sealing device

Structures: Composite Bridge Structures

Drive: Main Motor Drive Power Rod

Transmission: Vertical motion of eccentric connecting rod

Quantity:5 Pieces

Lenth: Hot Knife 800mm cool Knife 400mm

7.Cross sealing device

Structure:Beam cushion type hot pressing structure

Drive: Main Motor Drive Power Rod

Transmission: Vertical motion of eccentric connecting rod

Quantity: 6 Sets /Zippers 1 Sets /Ultrasonic

8.Traction of Film

Structure: Pneumatic cot press friction type

Drive: Digital AC Servo System with Medium Inertia(Japan 1Kw, 2000r/m, servo motor)

Transmission: M-type synchronous belt wheel drive, speed ratio 1:2.4

Control Form: Computer Centralized Control

Detection mode: photoelectric sensor combined with proximity switch integrated control

9.Intermediate tension

Structure: Pneumatic cot press friction type

Control Form: Computer Centralized Control. Dynamic Motion Compensation

Detection mode: contactless proximity switch

Adjustment range of floating roller tension: 0-0.6Mpa air pressure, compensation range of intermediate traction motor 1-10mm (computer set, automatic interpolation)

10.Main transmission device

Structure: Crank rocker push-pull four-bar structure

Drive: 5.5KW Inverter Drives 4KW Three-phase Asynchronous Motor

Drive: Main drive motor belt 1:15 reducer

Control Form: Computer Centralized Control

Motion mode: the motion of the main motor drives the vertical movement of the frame up and down

11.Automatic positioning device

Mode: (1) Precision of computer automatic length control mode: Accuracy≤0.5mm

(2) Tracking and detection accuracy of reflective photoelectric sensor: Accuracy≤0.5mm

Photoelectric search range: 0 ~ 10 mm (range size computer can set automatic search)

Corrected Compensation Range: +1~5 mm

Location Correction: Servo Motor Controlled by Computer Feedback Signal

Photoelectric and servo motor encoder feedback computer control

12.Temperature control device

Detection mode: thermocouple detection K type

Control mode: computer centralized control, solid state relay driving PID regulation

Range of Temperature: 0-300 degrees

Temperature measuring point: Middle section of electric heating block

13.Cutter

Structure: upper cutter + adjusting device + fixed lower cutter

Form: Pneumatic Pull-up Shear Type of Guide Rod Linear Bearing

Transmission: Borrowing Eccentric Shaft Power

Adjustment: Horizontal movement, pull handle adjustable tangent angle

14.zip device

Longitudinal cold ironing: composite bridge structure

Zipper direction: left, middle, right guide plate longitudinally arranged

Transmission: borrowing the vertical motion of the eccentric linkage structure of the main engine

Zipper traction: synchronous traction by 1 1Kw (Japanese imported) servo motor and main engine

Quantity: 2 groups

Length: hot sealed 800mm cooling 400mm

15,.stand bag insert device

Structure form; horizontal discharge (composed of magnetic powder brake, cylinder, pendulum rod, AC speed regulating motor, traction roller, sensor, rotary encoder)

Insert traction: mainframe traction sub-belt insert synchronous

Discharge: swing arm control discharge motor as traction

Control form: sensor and rotary encoder (floating pendulum motion position)

Transmission: coupling connection

Opposite side: screw structure, manual adjustment

Tension: constant tension of discharge

Discharge shaft: gas rising shaft

Punch: photoelectric tracking, mainframe computer centralized control, pneumatic stamping. Manual adjustment of punching position or punching position motor drive

16.Side feeder

Structure: horizontal reciprocating rod receiving structure

Drive: ac motor drive

Control system: sensor

17.Punching device

Structure: pneumatic die for bow seat

Control Form: Computer Centralized Control

Drive: Electronic Switch Driven Solenoid Valve (DC24V)

Punching seat: manual horizontal fine-tuning structure of guideway support bow seat

Adjustment: +12mm

Air Cylinder: Pneumatic Control

Mould: Ling hole and round hole

Quantity: 2 groups

18.Multiple delivery device

Structure: pneumatic cushion asynchronous insulation

Control Form: Computer Centralized Control

Drive: Electronic Switch Drive Solenoid Valve (DC24V DC)

Movements:7 groups of cross-seal asynchronous movements

Number of times to send: 2-6 times to send (can be set in the computer)

19.Automatic conveyor Device

Structure: O-type horizontal station

Drive: solid-state relay drive, gear reduction single-phase motor

Transmission:Helical gear transmission

Conveying distance and quantity: set freely in computer

Control Form: Computer Centralized Control

Supporting Facilities (Users Solve by themselves)

Power supply: three-phase 380V + 10% 50Hz air switch 150A

With Zero Line, Ground Line (R.S.T.E)

Capacity: > 65Kw

Gas source: 35 liters/min (0.6 Mpa)

Cooling water: 15 liters/min

| Model | Quantity | Brand | ||

| Traction Parts | Traction motor | Servo 1KW.1.5KW | Each 2 Pieces | Panasonic |

| Main Pneumatic Components | 1 | China | ||

| Main transmission part | Retarder | 1:15 | 1 | SEW |

| Frequency converter | 5.5kw | 1 | Taian | |

| Unwinding parts | Frequency converter | 0.75KW | 1 | Taian |

|

Control parts |

PLC | 1 | Panasonic | |

| Liquid crystal display | 10.4 inch | 1 | AOC | |

| Solid state relay | 24 | Wuxi,China | ||

| Magnetic powder brake | 2 | 3 | ||

| Rectifying device | 1 | Wuxi | ||

| Photoelectric switch | 5 | Hangzhou |

Product detail pictures:

Related Product Guide:

Our workforce through professional training. Skilled professional knowledge, solid sense of service, to fulfill the services demands of consumers for 2021 Latest Design Paper Bag Punching Machine - High Speed Bag Making Machine SLZD—D600 for Plastic Composite Film – Eureka , The product will supply to all over the world, such as: Nigeria, Surabaya, Czech Republic, The working experience in the field has helped us forged a strong relations with customers and partners both in domestic and international market. For years, our products have been exported to more than 15 countries in the world and have been widely used by customers.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.