900A Rigid Box and Case Maker Asssembly Machine

| Model | YY-900A |

| Dimension | 3600*2000*2000mm |

| Machine Weight | Around 800KG |

| Speed | 22-30PCS/min |

| Max. Case Size | 900*450mm |

| Min. Case Size | 90*95mm |

| Min. Case Size | 130*130mm |

| Max. box height Size | 120mm |

| Precision Positioning | ±0.1mm |

| Power Supply | AC220V |

| Power | 8KW |

| Air Pressure | 0.6Mpa |

| Servo Motor |

Panasonic |

| Servo Driver | |

| Photosensor | |

| Vacuum Switch | |

| Power Switch |

Meanwell |

| PLC |

HUICHUAN |

| Proximity Switch |

Schneider Electric SA |

| Linear Module |

CCM |

| Pneumatic Element |

AIRTAC |

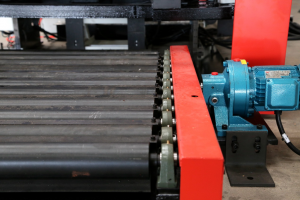

1.CASE FEEDING COMPONENT

Adopting a downward suction structure to solve the problem of double or multiple case feeding and ensures that the case does not scratch.

2. GLUING COMPONENT

Gluing is controlled by Japanese Panasonic servo motor, which makes the glue more precise. Optional hot and cold double glue system to make the product more viscous and anti-opening.

3. BOX SEEDING COMPONENT

The feeding direction of the box which customers operate according to the actual production situation can be vertical and parallel to the main machine.

4. POSITIONING COMPONENT

Positioning is controlled by Japanese Panasonic servo motor, which makes the positioning more precise.

5. MOLDING COMPONENT(Optional)

The flip-up structure is adopted to automatically flang the book-shaped box, making the gap smaller after the product is assembled.