ARETE452 Coating Machine for Tinplate and Aluminum Sheets

ARETE452 coating machine is indispensable in a metal decoration as the initial base coating and final varnishing for tinplate and aluminum. Widely applied in three-piece can industry ranging from food cans, aerosol cans, chemical cans, oil cans, fish cans to ends, it helps users to realize higher efficiency and cost-saving by its exceptional gauging precision, scrapper-switch system, low maintenance design.

The machine comes with three parts feeder, coater and inspection enabling to finish coating at preprint and varnishing at postprint by working with the oven. ARETE452 coating machine performs high cost efficiency by its unique technology derived from proven experiences and practical innovations:

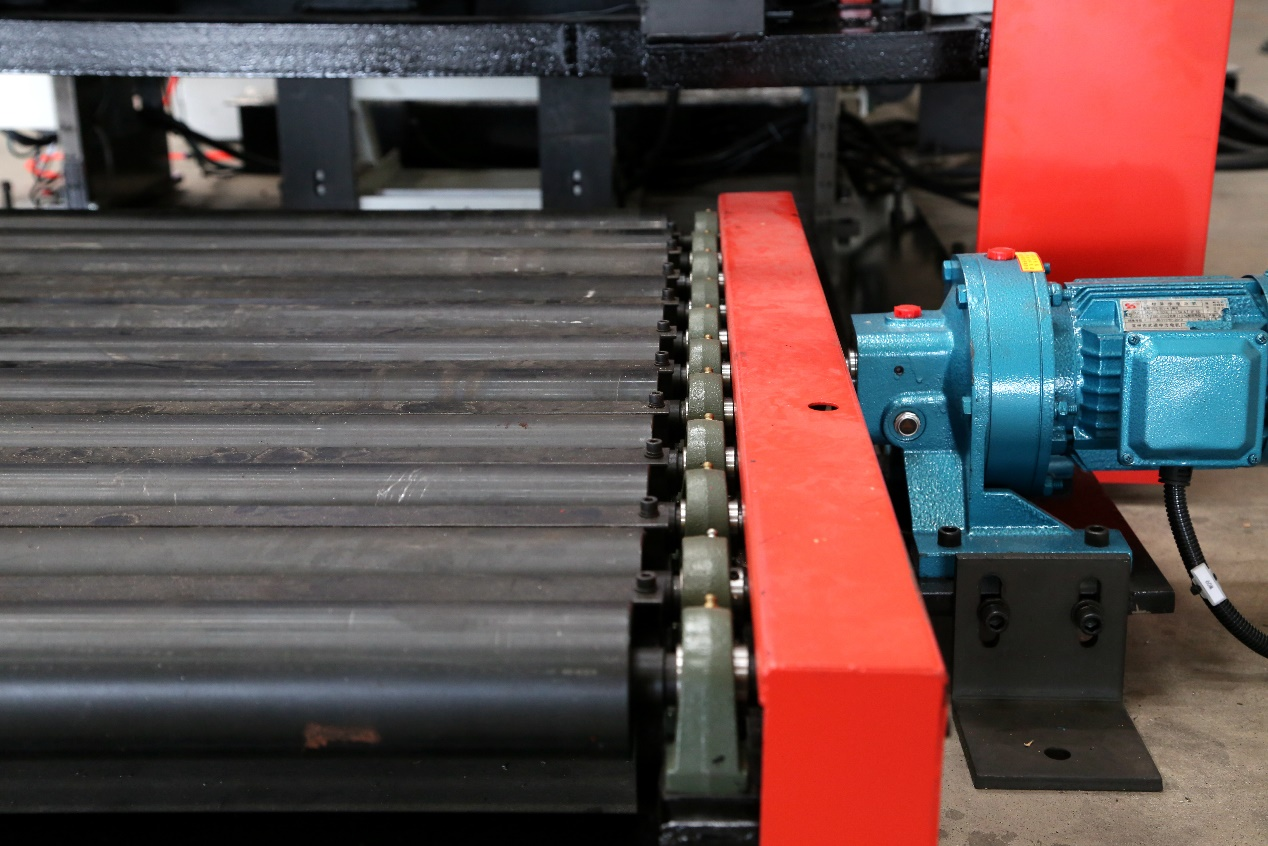

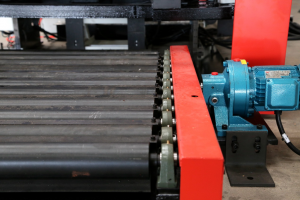

• Stable, powerful, continual transport by innovated air blowing, linear gauging and driving systems

• Cost saving in solvent and maintenance by the flexible patent double-scrapper design

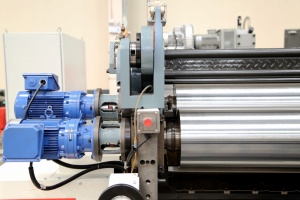

• Best leveling thanks to qualified separate motorized control

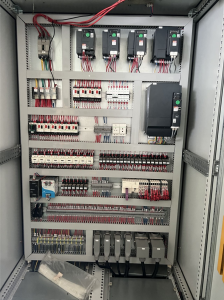

Operator-friendly design for double-side adjust, ergonomic panel, pneumatic control system especially in scrapper adjust and rubber roller dismantle.

To define your favorite models, please click ‘SOLUTION’ to find your target applications. Don’t hesitate to pop your inquires by mail: vente@eureka-machinery.com

| Max. coating speed | 6,000 sheets/hr |

| Max. size of sheet | 1145×950mm |

| Min. size of sheet | 680×473mm |

| Thickness of the metal plate | 0.15-0.5mm |

| Height of feeding line | 918mm |

| Size of rubber roller | 324~339(plain coating)、329±0.5(spot coating) |

| Length of rubber roller | 1145mm |

| Distributing roller | φ220×1145mm |

| Duct roller | φ200×1145mm |

| Capacity of air pump | 80³/ h+165-195m³/ h46kpa-48kpa |

| Power of main motor | 7.5KW |

| Dimension of press(LжWжH) | 7195×2200×1936mm |

SMOOTH TRANSPORT

EASY OPERATION

COST SAVING

HIGH QUALTY

LEVERLING