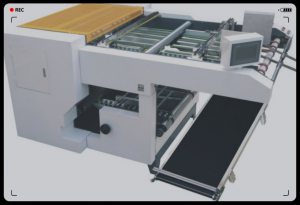

Automatic Digital grooving machine

SLZ-928/938 is automatic grooving machine, it is specially designed for notching V shape grooving , its advantage which can do several material, such as thin paperboard,industrial cardboard, gray cardboard, paperboard and other cardboard materials. High accuracy, High stability, High precision.

Help the user to produce the hardcover product, case maker, different kinds of box, etc

It has high notching accuracy, dustless, little noise, highly effective,energy conservation, environmental protection. Help you to solve the package grooving problem.

Performance:

1. Automatic feeding system ,in high feeding speed.

2. Automatic Self-aligning device is equipped with wear-resistant rubber wheels to ensure the stability of edge correction,and also improve the accuracy and security greatly,easy to operate.

3. The core part of drum is made of seamless steel,polished,chrome plated,aging treatment,precipitation,so it is not only very round,the beating accuracy is up to 0.03mm,high durability,long life,the grooving accuracy is +/-0.05mm .

4. Digital indicator help user to get the best precise positioning up to +/-0.01mm,easy for confirm knife position (include cutting depth and left & right moving distance) , keep the surface of drum smooth without any scratch from knife , enhance speed of adjusting the knife .

5. Automatic receiving part for collecting the final board.

6. Automatic groove waste delivery out of the machine,save labor,improve output.

| Model no.: | SLZ-928/938 |

| Material size: | 120X120-550X850mm(L*W) |

| Thickness: | 200gsm---3.0mm |

| Best Accuracy: | ±0.05mm |

| Normal Accuracy: | ±0.01mm |

| Fastest Speed: | 100-120pcs/min |

| Normal Speed: | 70-100pcs/min |

| Groove degree: | 85°-130° adjustable |

| Power: | 3.5kw |

| Max grooving lines: | 9 grooving lines max (928 model install 9sets knife holder ) |

| 12 grooving lines max(938 model install 12 sets knife holder)

|

|

| Knife holder standard of 928 model : | 9 sets knife holder(5set of 90º +4 set of 120º) |

| Knife holder standard of 938 model : | 12 sets knife holder(6 set of 90º +6 set of 120º) |

| V shape min distance: | 0:0(no limited) |

| Grooving knife position device: | Digital indicator |

| Machine size: | 2100x1400x1550mm |

| Weight: | 1750 kgs |

| Voltage: | 380V/3 phase/50HZ |

Saili Company is providing professional grooving solution for packaging industry.The machine can be customized.

Let's make your packaging much more beautiful and professional than others.

To feed the material by belt automatically, it is simple for operating and adjust for user.

Design the automatic correction system as guider in order to keep the cardboard which is conveyor straightly.

Automatic correction guider system

Drum type structure with 2 girders

2 girders with 12sets knife holder for grooving, the grooving knife distance between 2 knives: 0:0(no limited), Standard knife holder with 6sets of 90º knife holder and 6sets of 120º knife holder

Knife holder with digital indicator for user to confirm the grooving depth and knife position through more easily.

Grooving knife holder with digital indicator

Automatic Grinder of knife together with machine

Grooving blade

Blade Life: usually the blade can working 20000-25000pcs after 1 time sharping. And 1pc blade can been sharpened about 25-30 times with good user.

Standard Machine parts together with machine for user:

|

Name |

Qty |

|

Grinder of knife |

1ea |

| Tool box((including 1set Allen wrench,straight screwdriver of 4 inch, open spanner,adjustable wrench,grater) |

1pc |

|

Grooving blade |

24pcs |

| Roller material: | Shanghai BAOSTEEL |

| Frequency changer: | Hope brand (If customer need change the brand, we also can use Schneiderbrand or another brand) |

| Low-voltage apparatus: | Eaton Muller brand |

| Machine main motor: | CHENGBANG,TAIWAN BRAND |

| Belt: | XIBEK,CHINA |

| Knife: | Special Tungsten alloy steel |

| Collector belt motor | ZHONGDA brand,China |

V shape on cardboard

V shape on material of the min thickness 200gsm

Two material two can make it, thickness from 200gsm to 3.0mm

Delivery time: within 7-15 days after receiving the deposit

Payment terms: 30% TT in advance, 70% payment before delivery

Installation: If the buyer need our factory to sent engineer go to install, the buyer will cover all expense of engineers visiting including round-trip tickets, local transportation, meals and loading expenses.