China New Product Automatic Stripping Machine – HTQF-1080CTR Automatic Stripping with Double Heads Blanking Machine for carton – Eureka

China New Product Automatic Stripping Machine – HTQF-1080CTR Automatic Stripping with Double Heads Blanking Machine for carton – Eureka Detail:

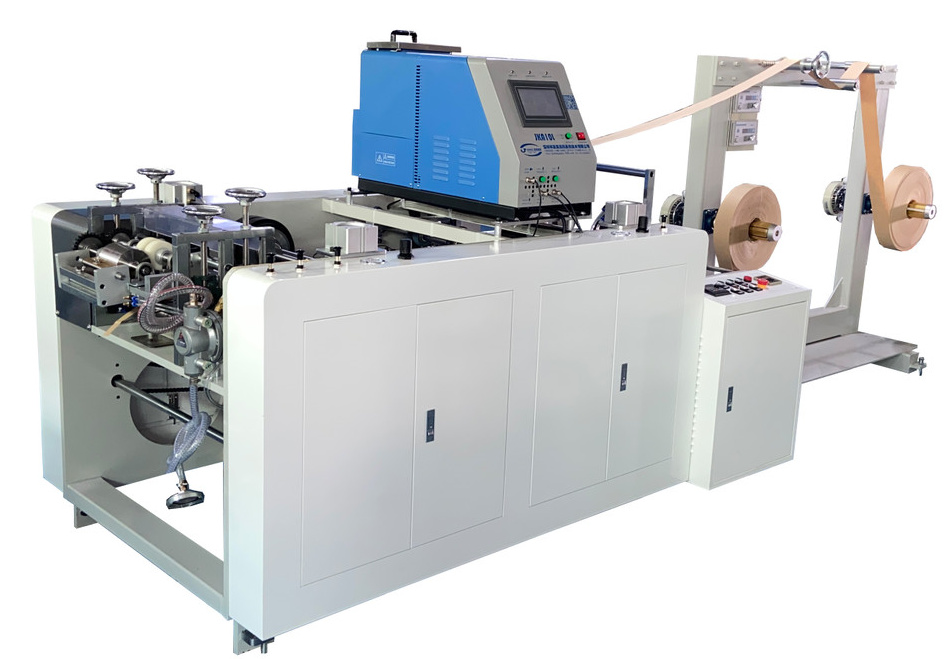

1. Taking out finished products after die cutting process, for waste stripping.

2. Applied for many die-cutted product such as labels, hang tags, business cards, gift boxes, food boxes, paper cups and other die cutting products in paper or plastic, PU leather.

3. Two work heads: one inner hole cleaning + one stripping head

4. Rotary head of stripping to take out the opposite direction die cutting products easily .

5.Automatically taking out product with manipulator arm and stack product onto delivery belt.

6. PLC controlled with smart & easy operation.

7. Automatic lubrication system for machine better maintenance.

8. Different shapes can be custom-made as customer requirement.

| Model | HTQF-920CTR | HTQF-1080CTR |

| Machine Size | L4200xW2250xH2020 | L4290xW2490xH2020 |

| Max sheet size (X x Y) mm | 920 x 680 | 1080 x 780 |

| Min sheet size (X x Y) mm | 550 x 400 | 650 x 450 |

| Max pile height / mm | 100 | 100 |

| Min pile height / mm | 40 | 40 |

| Work table height mm | 850 | 850 |

| Max product size to be punched out | 420 x 420 | 390 x 390 |

| Min. product size to be punched out | 30*30 | 30*30 |

| Stripping speed times/min | 15-22 | 15-22 |

| Max. force (bar) | 70 | 70 |

| Air consumption L/min | 3 | 3 |

| Manipulator Grip Range /mm | 30-260mm | 30-300mm |

| Manipulator Grip Weight | 50-1500g | 50-1800g |

| Max Power | 5kw 380V | 5kw 380V |

| Net Weight | 2.9T | 3.2T |

| Package Size | 3700x1900x2200 | |

| Gross Weight | 2.5T | 3T |

| Gross Weight | 3.6T | 4.0T |

1. Taking out finished product after die cutting process,for waste stripping.

2. Applied for many die-cut products such as labels, hang tags, business cards, gift box, food box, paper cups and other die cutting products in paper or plastic, PU leather.

3. PLC controlled with smart & easy operation.

4. Automatic lubrication system for machine better maintenance.

5. Different shape products can be custom-made as customer requirement.

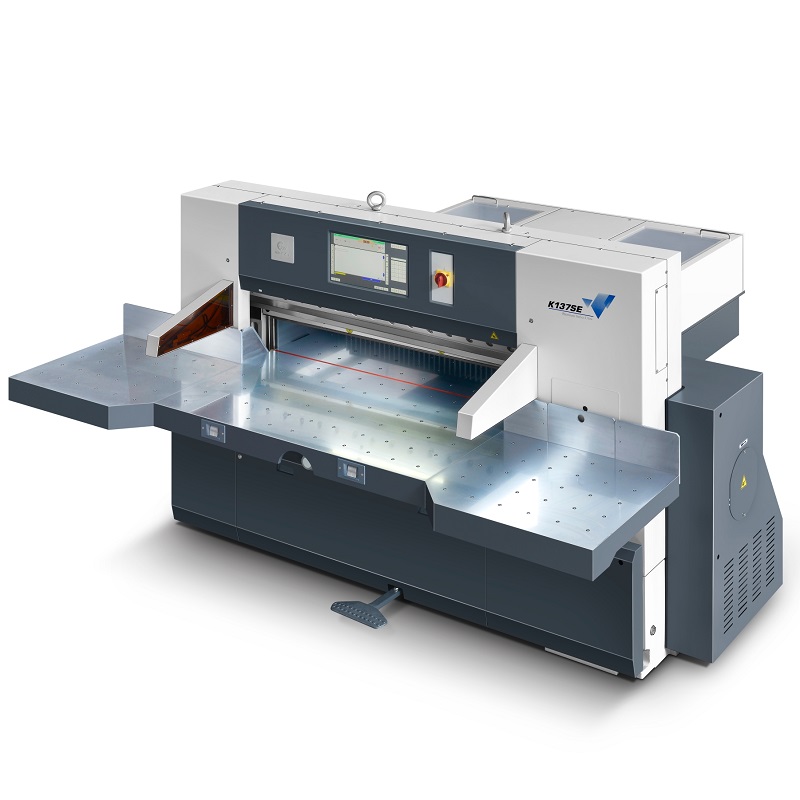

Adjustable hydraulic system

Safety fence

Centralized lubrication system

Paper gauge with hidden motor and ball screw

Product detail pictures:

Related Product Guide:

Our solutions are widely recognized and trusted by consumers and will meet up with constantly developing financial and social requires for China New Product Automatic Stripping Machine – HTQF-1080CTR Automatic Stripping with Double Heads Blanking Machine for carton – Eureka , The product will supply to all over the world, such as: Wellington, Milan, Sri Lanka, As an experienced manufacturer we also accept customized order and we could make it the same as your picture or sample specification. The main goal of our company is to live a satisfactory memory to all the customers, and establish a long term business relationship with buyers and users all over the world.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.