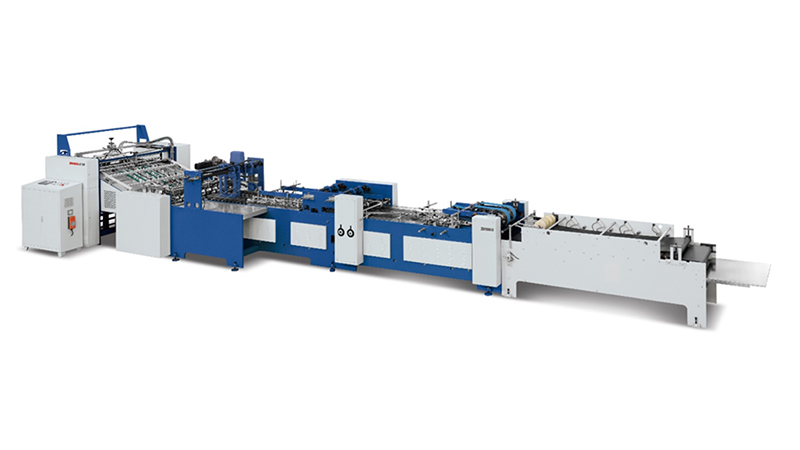

China New Product Automatic Vertical Laminating Machine – VISTEN Automatic Flexo High Speed printing &slotting & glue in line – Eureka

China New Product Automatic Vertical Laminating Machine – VISTEN Automatic Flexo High Speed printing &slotting & glue in line – Eureka Detail:

|

Name |

Amount |

| Feeding unit( Lead Edge Feeder ) |

1 |

| Printer unit( Steel anilox roller +rubber roller) |

6 |

| Slotting unit |

1 |

| Auto gluer |

1 |

Automatic Flexo Printing & Slotter & Die cutter Machine of VISTEN

Functional configuration and technical parameters.

I. Computer operation control unit

1.Memory to zero: the machine wipe version or a small amount of plate changing in the course of their work for open machine, after the close of the machine can automatically restore the original position.

2.Controlled anilox roller lift: when a group of temporary does not require printing, can control the group anilox roll need not decline, and thus do not need to clean the ink roller.

3.Automatically trimming paper: freely set the time of trimming paper interval to make the operation more flexible, suitable for the individual operating habits

4.Position to zero: the machine can make the plate position to zero so that the location of the plate can be a place, the test printed two cardboard can search the correct place.

5.Main motor screen display speed, feed, trimming, skip.

6.The screen display the number of orders and set the number of actual production, and the machine can stop automatically after completion printing, anilox automatically far away the plate.

7.Orders default: you can required for processing orders on computer color screen only need to enter the carton length, width, height and angle cutting width, trimming the width of five each data intelligence data to complete nearest homing; (can store 999 orders)。

Data comprises:

(1) The printing position of each color.

(2) Slotter position.

(3) Box high position.

(4) The cartons front width, side width.

(5)The cardboard’s height, width and so on

Intelligent nearest homing directly after the input is complete without host first positioning one direction to zero and knife disk, baffle and first go back to the origin of the re-positioning of the low work efficiency.

8.Data Retention: When the data has been correctly processed products, the current data is automatically saved for the next use; automatically adjusted in accordance with the directive when used again, saving tune regulation time.

II. Feeding unit (one unit )

Feed accuracy:±1mm

1.Machine clutch

(1)Electric control machine clutch attached bells, the marching continued ringing warning, to ensure the safety of the operating personnel.

(2)Every landline and Taiwan, Devices emergency stop switch can be internal control to stop the machine moving, to ensure the security of the internal operations staff.

(3)The pneumatic interlock device.

(4)The whole total lock manner.

2 .Absorbing dust system

(1)Equipped with a fine crumbs dust removal machine, a large number to eliminate the the cardboard printing surface impurity, and improve the printing quality.

3.Feeding roller

The outer diameter of the upper feeding roller is Φ142.68mm.(1200)

(2)Seamless pipe, wrapped wearable rubber, and to do the balancing correction。

The under feeding roller is Φ157.45mm and embossed hard chrome plating.(1200)

(4)The feed roller gap the scale worm gear adjustment, the adjustment range of 0-12mm

.4.Second set of upper and lower feed roller

(1)Seamless pipe, wrapped in wear-resistant rubber, and to do the balancing correction.

The lower roller the outside diameter is Φ157.45mm and embossed hard chrome plating.(1200)

(3)The feed roller gap adjust by person , the adjustment range of 0-12mm.

5.The automatic feeding’ s operational control

(1), feed around the bezel, push the cardboard after the block carton electric adjustment, and paper trimming function

(2), the back kick suction assisted feeding system, according to the degree of cardboard bending, do the adjustment of air volume. (Optional servo control lead edge feeder system)

(Our company produces the leading edge of the paper feeding mechanism servo control, with independent intellectual property rights, and the economy is very obvious, only to replace the standard timing belt that can ensure the normal use of the edge feeder with a synchronous tracking, replace the feed roller seamless transmission and other new features, can effectively ensure the correctness of the feed, to avoid the backlash can not be solved by a mechanical cam transmission, mechanical wear and tear after long-term use, the feed roller replacement inconvenience, high-speed transmission instability and other factors.)

III.Printer unit(one colour one set)(Optional scraper system)

Printing precision:±0.5mm

1.Printing roller

1)、The outer diameter Φ393.97mm (containing plate diameter is Φ393.97mm)。(1200)

The outer diameterΦ443.2mm(containing plate diameter isΦ457.6mm)。(1400)

2), surface grinding, hard chrome plating.

3),Dynamic and static balance correction, smooth operation.

4),Ratchet fixed volume version of the shaft.

5), Adopts hanging mechanism to convenient and fast install, for 10mm hanging version of the article

6), loading and unloading printing plate, foot switch electric control reversing.

2. Printing embossing roller

1)Outer diameter ofΦ172.2mm。(1200)

2)、Steel pipe surface grinding, hard chrome plating.

3)、Balance correction, smooth operation

4)、Scale manually adjust the printing impression roller gap adjustment range of 0-12mm

3、Steel anilox roller(Optional ceramic anilox roller)

1)Outer diameter ofΦ206.65mm。(1200)

2)、The engraving textured steel surface with a special processing。

3), dot, even on ink, durable, and durable.

4), extend the time within which a plate and rubber roller life, sculptured by a special process.

4, rubber roller

1)Outer diameter of外径为Φ211mm。(1200)

2), steel coated with corrosion-resistant rubber.

3), special grinding rubber roller, ink effect.

5, the phase adjusting mechanism

1)Planetary gear structure.

2) The phase of the digital display instructions to make the operation more convenient, intuitive and accurate.

3)、The printing phase with PLC touch screen control and electric digital 360 adjustment (operation stop can be adjusted). Phase modulation accuracy of up to 0.15 mm.

4)、Print roller inverter is used to adjust the phase, dynamic and static under any position adjustments, fine-tuning accuracy up to 0.10 mm, such as location dislocation can always reset to zero after the unit has been removed, accuracy up to 0.5 mm.

6、Ink circulation

1), pneumatic ink pump, ink stability, simple operation and maintenance.

2), the provincial ink cleaning device, which can effectively save ink.

3), the ink filter, filter the impurities.

7, the printing phase fixtures

1), electromagnetic the brake brake mechanism.

8, the axial adjustment mechanism

1), electric axial adjustment mechanism.

2), digital display type position indicator, make the operation more convenient, intuitive and accurate.

IV. Slotter unit(one set)

Slotting precision: ± 1.5mm

1, wire wheel

Shaft diameterΦ154mm,after two grinding, hard chrome plated, smooth move. (1200)

2)、Line pressing roller gap the scale manual adjustment, the adjustment range 0-12mm.

3)、The pressure line round the use of quality imported polyurethane

2.Slot knife sliding adjustment mechanism

1)Shaft diameter Φ174mm after two grinding, hard chrome plated, smooth move. (1200)

2)、Slotted knife width of 7mm.

3)、Alloy tool steel heat-treated, grinding toothed slotted knife, hardness and toughness is superb. (Taiwan )

4)、Alloy steel after heat treatment, grinding trimming knife, sharp knife, and high precision.

5)、Pressure line wheel, guide roller, slot knife traverse position, the use of electric button synchronization control.

6)、Pressure line wheel, guide roller, slot knife traverse position, the use of electric button synchronization control.

Slotted phase adjusting mechanism

1), the planetary gear structure.

2), before slotting phase, after the knife with touch screen and electric button dual control and electric digital 360 degrees (stop can be adjusted dynamically).

3), slotted knife horizontal movement adopts electric adjustment (stop dynamic can be adjusted).

VI.Glue System:

1.Simple maintenance, reducing maintenance costs.

2.Peristaltic pump suction cycle, reducing paste waste.

Transport Unit:

Can cope with various thickness of cardboard with a gap adjusting device, receives from the press out of the vertical cardboard.

Folding Unit:

1.Installation new folding system, in line at the precise folding, trimming the gap can be up and down.

2.Using suction type main belt, the smooth discharge of the final stage in the folding carton, cardboard edges to prevent distortion.

3.Left and right two fold belt with a separate motor drive, according to the length and width dimensions individually controlled speed.

Counting and Eject unit

1.Small cardboard can achieve high-speed running smoothly.

2.Externally bonded type, portable hole, vent-type can also be stable, smoothly stick the paper box.

Operation Unit:

1.Configure color LCD touch screen, you can display a variety of alarm information and operational information.

2.Achieve remote control.

VII. Transmission gear

The main drive gear

1), by 20CrMnTi alloy steel, carburizing and grinding gears.

2), six precision (similar) with auto gearbox gear smooth operation, low noise, hardness HRC58-62, long life, not less than 10 years of basic wear and tear, can achieve long-term printing marks.

2.Connection ring

1),Free connection ring, can be connected to the shaft and the gear, the use of the large torque will not gap, installation and maintenance more convenient, allows the machine to drive long-term high precision to ensure print registration.

VIII. Main technical parameters

|

Specification |

2500*1200 |

|

|

Max speed (pcs/min) |

160 |

|

|

Max feeding size(mm) |

2500*1200 |

|

|

Min feeding size (mm) |

650*330 |

|

|

Skip feeding size(mm) |

2500*1400 |

|

|

Thickness of paper(mm) |

2-10 |

|

|

Max printing size (mm) |

2450*1150 |

|

|

Print plate depth (mm) |

7.2 |

|

|

Min slotter interval(mm) |

(mm)Positive cut |

120*120*120*120 |

|

(mm)Reverse cut |

200*80*200*80 |

|

Product detail pictures:

Related Product Guide:

With this motto in mind, we've come to be one of quite possibly the most technologically innovative, cost-efficient, and price-competitive manufacturers for China New Product Automatic Vertical Laminating Machine – VISTEN Automatic Flexo High Speed printing &slotting & glue in line – Eureka , The product will supply to all over the world, such as: New York, Lebanon, Surabaya, We have been very responsible for all details on our customers order no matter on warranty quality, satisfied prices, quick delivery, on time communication, satisfied packing, easy payment terms, best shipment terms, after sales service etc. We provide one-stop service and best reliability to our every customers. We work hard with our customers, colleagues, workers to make a better future.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!