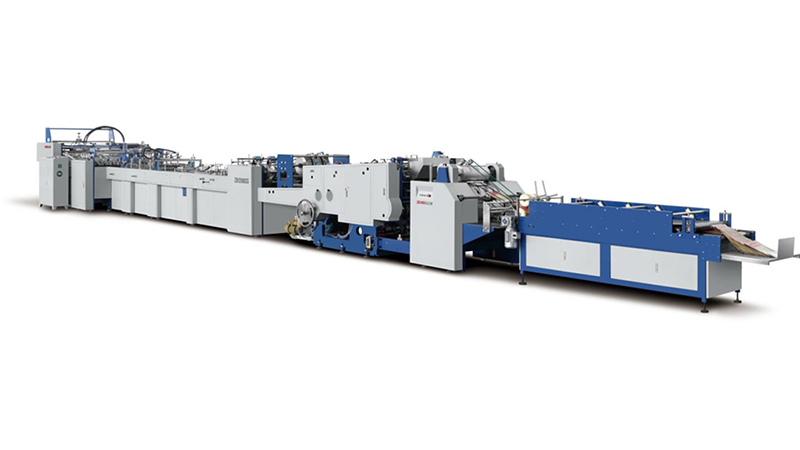

China New Product Flute laminator – Semi-Automatic Flute Laminating machine(Height top Feeder) for corrugated cardboard – Eureka

China New Product Flute laminator – Semi-Automatic Flute Laminating machine(Height top Feeder) for corrugated cardboard – Eureka Detail:

1. The heightened top paper feeding table facilitates the stacking of the bottom paper during the production process and improves the production efficiency.

2. Flip-up bridge board, easy to clean. Intermittent water circulation cleaning system,.

3. The humanized design that the bottom paper is automatically fed and the top paper is pushed forward manually makes the paper feeding easier and the positioning more accurate.

4. The flexible front position is specified, the bottom paper is not advanced; and the bottom and top paper are adjustable before and after they are laminated.

5. It is suitable for bonding the bottom cardboard and cardboard of 350 grams or more, the cardboard and A/B/C/D/E/F and double-layer corrugated cardboard, and the corrugation and corrugation.

6. Intelligent control and flattening can save electricity and control the stacking distance.

7. Adopt high-precision glue blocking device to save glue.

8. You can choose the way of side feeding paper.

※ Optional: Optional PLC integrated program module control, extended flattening section, auxiliary lifting of the paper stacking table.

|

Model |

FMB-1300-G |

FMB-1450-G |

FMB-1650-G |

|

Max. Sheet Size |

1300x1100mm |

1450x1100mm |

1650x1300mm |

|

Min. Sheet Size |

350x400mm |

350x400mm |

350x400mm |

|

Total power |

9kw |

9kw |

12kw |

|

Speed |

0-108m/min |

0-108m/min |

0-90m/min |

|

Weight |

3.1t |

3.5t |

5.3t |

|

Dimensions |

9000x1950x1900mm |

9000x2150x1900mm |

9200x2500x1900mm |

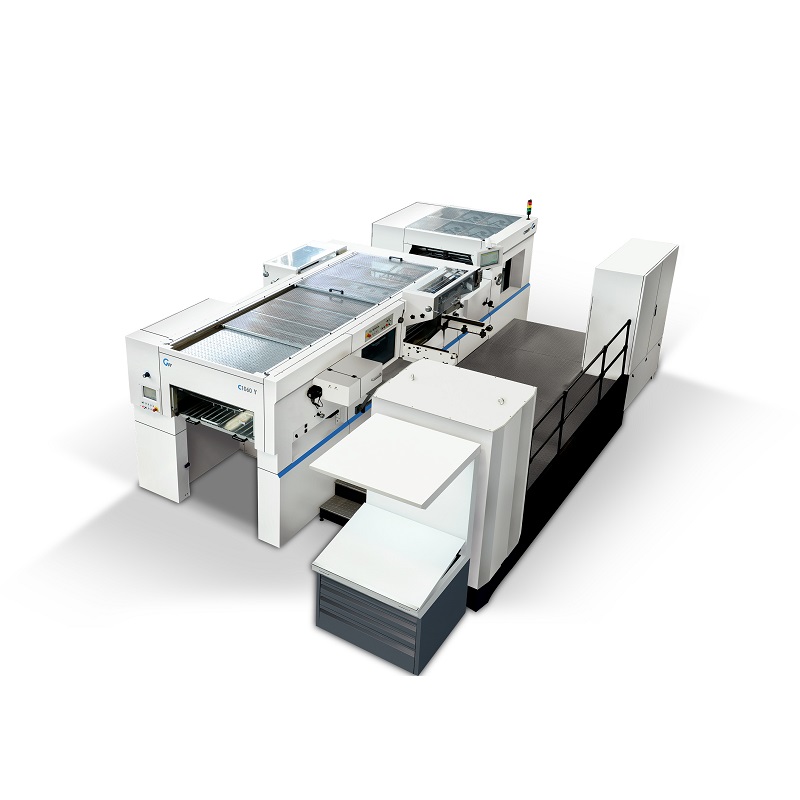

Bottom paper feeding motor

PLC CONTROL

Gluing pump motor

Main motor and machine are with dust cover

Floating pressing unit, automatic pressure adjust

Product detail pictures:

Related Product Guide:

To regularly increase the management program by virtue from the rule of "sincerely, good religion and high quality are the base of enterprise development", we greatly absorb the essence of linked products internationally, and constantly produce new goods to satisfy the calls for of shoppers for China New Product Flute laminator – Semi-Automatic Flute Laminating machine(Height top Feeder) for corrugated cardboard – Eureka , The product will supply to all over the world, such as: Georgia, Cologne, Zurich, We are your reliable partner in international markets with the best quality products. Our advantages are innovation, flexibility and reliability which have been built during the last twenty years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sales and after-sales service ensures strong competitiveness in an increasingly globalized market.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!