China New Product Flute laminator – ZGFM Automatic high speed flute laminating machine – Eureka

China New Product Flute laminator – ZGFM Automatic high speed flute laminating machine – Eureka Detail:

Sizes Available

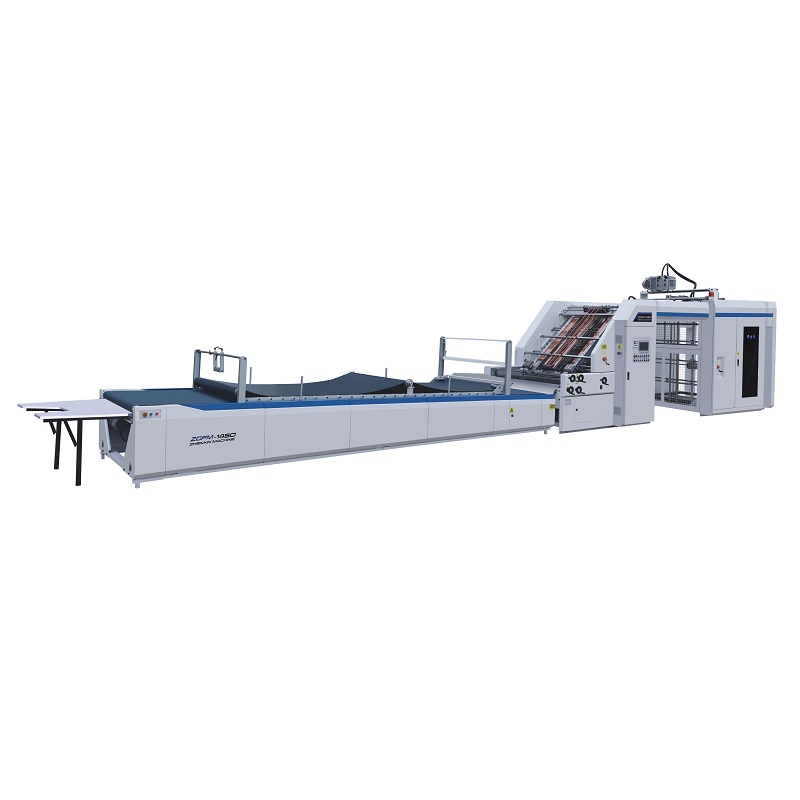

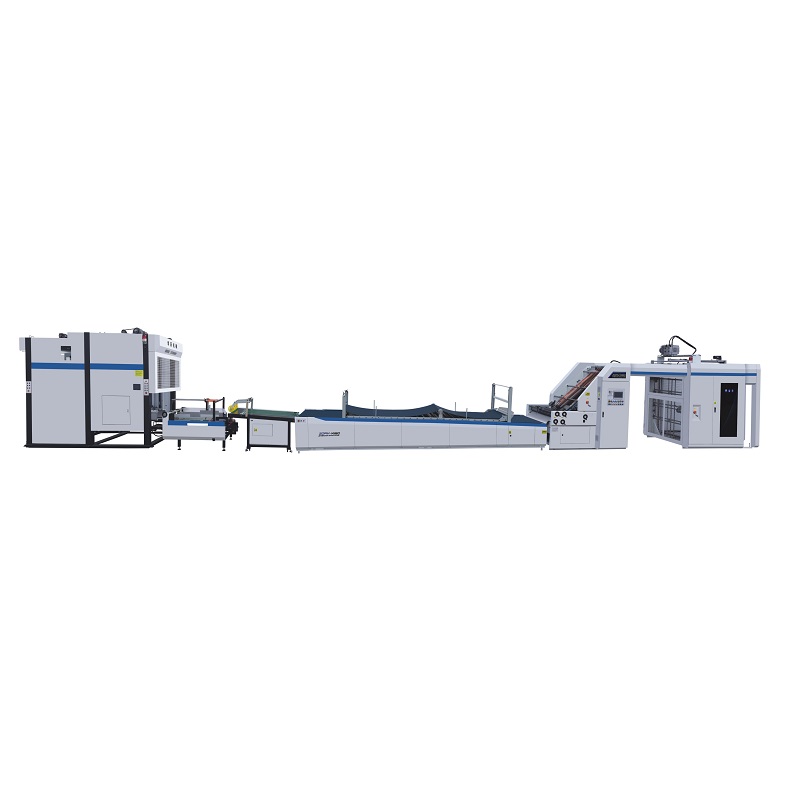

ZGFM series flute laminator come in three sheet sizes.

1.1 Function:

The paper can be laminated with paperboard to increase the strength and thickness of the material or special effects. After the die-cutting, it can be used for packaging boxes, billboards and other purposes.

1.2 Structure:

A. Top sheet Feeder: It can send stacks of 120-800gsm paper from above.

B. Bottom sheet feeder: It can send 0.5~10mm Corrugated/paperboard from below.

C. Gluing mechanism: The glued water can be applied to the fed paper. Glue roller is stainless steel.

D. Calibration structure-Fits the two papers according to the set tolerances.

E. Pressurizing Conveyor: Presses the attached paper and conveys it to the delivery section.

The frames of this series of products are all processed at one time by a large-scale machining center, which ensures the accuracy of each station and ensures more stable operation of the equipment

1.3 Principles:

The top sheet is sent out by the upper feeder and sent to the start detector of the positioning device. Then the bottom sheet is sent out; after the bottom paper is coated with glue, the top paper and the bottom paper are respectively conveyed to the paper Synchronous detectors on both sides, after the detection, the controller calculates the error value of the top and bottom sheet, servo compensation device on both sides of the paper adjusts the paper to a predetermined position for splicing, and then pressurizes the conveying. The machine presses the paper and conveys it to the delivery machine to collect the finished product.

1.4 applicable materials for laminating:

Paste paper — 120 ~ 800g/m thin paper, cardboard.

Bottom paper—≤10mm corrugated ≥300gsmpaperboard, single-sided cardboard, multi-layer corrugated paper, pearl board, honeycomb board, styrofoam board.

Glue – resin, etc., PH value between 6 ~ 8, can be applied to the glue.

Structural features:

Adopting the world’s leading transmission control system, input paper size and system will auto-tuning

Computerized high-speed laminating, up to 12,000 pieces per hour.

Stream-type air supply head, with four sets of forward nozzles and four sets of suction nozzles.

Feed Block adopts low stack cardboard, which can fit the paper to the pallet, and can install track-assisted pre-stacker

Use multiple sets of electric eyes to detect the advance position of the bottom line, and make the servo motor on both sides of the face paper to independently rotate to compensate the upper and lower paper alignment, which is accurate and smooth.

Full-function electronic control system, using human-machine interface and PLC program model display, can automatically detect operating conditions and work records.

Automatic glue replenishment system can automatically compensate for lost glue and cooperate with glue recycling.

ZGFM high speed laminating machine can be connected with automatic flip flop stacker to save labor.

| Model | ZGFM1450 | ZGFM1650 | ZGFM1900 |

| Max size | 1450*1450mm | 1650*1650mm | 1900*1900mm |

| Min size | 380*400mm | 400*450mm | 450*450mm |

| Paper | 120-800g | 120-800g | 120-800g |

| Bottom paper | ≤10mm ABCDEF corrugated board ≥300gsm cardboard | ≤10mm ABCDEF corrugated board ≥300gsm cardboard | ≤10mm ABCDEFcorrugated board ≥300gsm cardboard |

| Max laminating speed | 150m/min | 150m/min | 150m/min |

| Power | 25kw | 27kw | 30KW |

| Stick accuracy | ±1.5mm | ±1.5mm | ±1.5mm |

1. BOTTOM SHEET FEEDING

Use imported Servo motor electric controlling system, with Japan NITTA suction belt to make suction power inverter, and belt cleaned by water roller; Patented technology to ensure corrugate and cardboard goes out smoothly and simple operation.

2. TOP SHEET FEEDING MECHANISM

High speed auto dedicated feeder, both paper lifting and feeding nozzle can freely adjust angle to the paper, thick or thin paper can be delivered rapidly and smoothly.

3. ELECTRICAL SYSTEM

Designed in the accordance with European CE requirement, ensure machine stability, high efficiency and low failure. Using human-machine interface and PLC combination, display all the information, such as warning, error detect, failures, and operating speed, etc on the screen at a glance.

4. PRE-STACK PART

Pre-stack pile of paper under the condition of non-stop, improve efficiency.

The special design of the pre stack paper frame, save time and effort.

5. TRANSMISSION

With imported double teeth belt drive and Switzerland ROSTA tension device ensure the drive accurate, stable and low noisy.

6. POSITIONING SYSTEM & GLUE ROLLER

The use of multiple sets of photoelectric sensor at bottom sheets relative position, control top sheets on both sides of the servo motor to do independent compensation action, so that accurate positioning of top paper and the bottom paper.

Stainless steel roller, never rust, after narrowly grinding, guaranteed the minimum amount glue coated evenly.

Down roller be cleaned by water roller.

7. TOUCH SCREEN OPERATION SYSTEM

It adopts the centralized control of the touch screen, realizes the man-machine dialogue with the high-resolution man-machine interface, and realizes the real-time dynamic monitoring of operation and fault, making it more convenient to adjust and troubleshoot

1.LEADING EDGE FEEDING SYSTEM*OPTION

This system is suitable for large size and thick bottom sheets.

2. SHAFTLESS SERVO FEEDER*OPTION

This system is for option, more suitable for long size top sheets.

3. TOP PAPER CORRECTION*OPTION

This system is for option, Fitting more accurately.

4. AUTOMATIC LUBRICATION SYSTEM*OPTION

|

Serial |

Part |

Country |

Brand |

|

1 |

main motor |

Germany |

Siemens |

|

2 |

touch screen |

Taiwan |

WEINVIEW |

|

3 |

servo motor |

Japan |

Yaskawa |

|

4 |

Linear guide slide and guide rail |

Taiwan |

HIWIN |

|

5 |

Paper speed reducer |

Germany |

Siemens |

|

6 |

Solenoid reversing |

Japan |

SMC |

|

7 |

Press front and rear motor |

Taiwan |

Shanteng |

|

8 |

Press motor |

Germany |

Siemens |

|

9 |

Main engine width modulation motor |

Taiwan |

CPG |

|

10 |

Feeding width motor |

Taiwan |

CPG |

|

11 |

Feeding motor |

Taiwan |

Lide |

|

12 |

Vacuum pressure pump |

Germany |

Becker |

|

13 |

Chain |

Japan |

TSUBAKI |

|

14 |

Relay |

Japan |

Omron |

|

15 |

optoelectronic switch |

Taiwan |

FOTEK |

|

16 |

solid-state relay |

Taiwan |

FOTEK |

|

17 |

promixity switches |

Japan |

Omron |

|

18 |

water level relay |

Taiwan |

FOTEK |

|

19 |

Contactor |

France |

Schneider |

|

20 |

PLC |

Germany |

Siemens |

|

21 |

Servo drivers |

Japan |

Yaskawa |

|

22 |

Frequency converter |

Japan |

Yaskawa |

|

23 |

Potentiometer |

Japan |

TOCOS |

|

24 |

Encoder |

Japan |

Omron |

|

25 |

Button |

France |

Schneider |

|

26 |

Brake resistor |

Taiwan |

TAYEE |

|

27 |

Motion controller |

America |

Parker |

|

28 |

Solid-state relay |

Taiwan |

FOTEK |

|

29 |

Air switch |

France |

Schneider |

|

30 |

Thermorelay |

France |

Schneider |

|

31 |

DC power system |

Taiwan |

Mingwei |

Product detail pictures:

Related Product Guide:

We're going to commit ourselves to giving our esteemed customers along with the most enthusiastically considerate providers for China New Product Flute laminator – ZGFM Automatic high speed flute laminating machine – Eureka , The product will supply to all over the world, such as: Sacramento, Swiss, Madagascar, Our company sticks to the principle of "high quality, reasonable price and timely delivery". We sincerely hope to establish good cooperative relationships with our new and old business partners from all parts of the world. We hope to work with you and serve you with our excellent goods and services. Welcome to join us!

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.