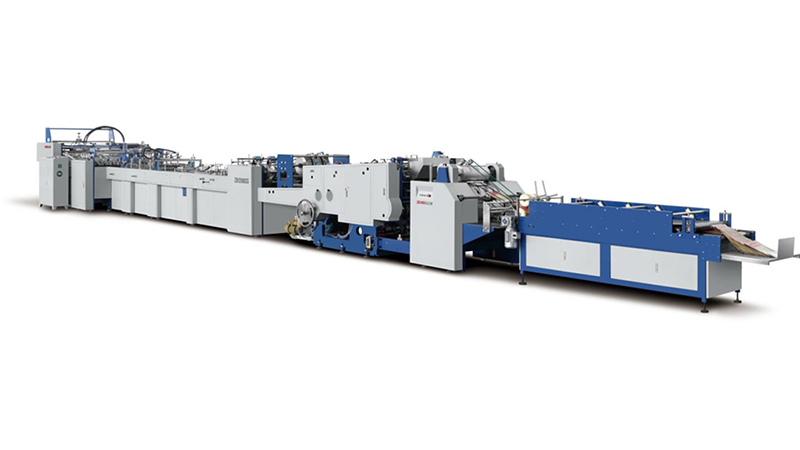

China New Product Window Pasting Machine – STC-650 Window Patching Machine – Eureka

China New Product Window Pasting Machine – STC-650 Window Patching Machine – Eureka Detail:

|

Model |

STC- 650 |

STC-1080A |

|

Max paper size(mm) |

650*650 | 1080*650 |

|

Min paper size(mm) |

100*100 |

100*100 |

|

Max window size(mm) |

380*450 |

780*450 |

|

Min window size(mm) |

40*60 |

40*40 |

|

Cardboard (g/㎡) |

200-1000 |

200-1000 |

|

Corrugated paper(mm) |

≤4.0 |

≤4.0 |

|

Film thickness(mm) |

0.05-0.25 |

0.05-0.25mm |

|

Max working speed(s/h) |

10000 |

10000 |

|

Total power (kw) |

8 |

10 |

|

Total weight (T) |

2 |

3 |

|

Dimension |

4750*1550*1600 |

4958*1960*1600 |

1. Feeder:

◆ The servo feeding type ensure the paper feeding smoothly.

◆ Imported NITTA belt, and imported SMC pneumatic components employed.

◆ Fast, steady and reliable of paper transferring.

◆ Our company has won the national patent for this part.

2. Rotation rubber roller(can pull-out):

◆ Single rubber roller cooperate with baffle to gluing.

◆ Avoid the waste of glue,reduce the volatilization.

◆ When the machine stopped,the rubber roller can rotation driving by the motor. Avoid the glue solidify on the face of rubber roller.

◆ When cleaning the rubber roller, this part can pull-out entirely,reduce cleaning time.

3. Gluing:

◆ Use automatic gluing instead of hand movement.

◆ This part can adjust the glue roller right or left、up or down.

◆ When the photoelectric sensor reacted the paper. If there are papers pass,the machine will use the air cylinder to control platform to uplift.

◆ If there are no papers pass,the platform will decline.

◆ Avoid the glue smear on the belt.

4. Suction belt:

◆ The two suction belts are wide and thick,increase service life.

◆ With the device of adjust the wind power.

◆ Can adjust wind power according to the sizes of papers.

◆ Ensure that no position offset.

5. Film transport:

◆ Film Transport is controlled by the servo motor.

◆ With high precision,make the error of cutting the film is less than 0.5mm.

◆ Adopt the touch screen to adjust the length of the film.

◆ Make the adjustment more convenient and efficient.

6. Roller knife:

◆ Quality alloy steel was adopted special heat treatment process to ensure long working hours.

◆ Use the touch screen to set the film length so that the machine can runs more accurate, stable and reliable.

7. Jog film cutting (Special for tissue boxes):

◆ Special design for the middle cutting of the film, such as tissue boxes point cut or long cut.

◆ Incision length is adjustable, ensure accurate and never shifting.

|

No. |

Model |

Name |

Model |

Quantity |

Remarks |

|

1 |

SQ1 |

Approach switch |

TL-05MB1 |

2 |

OMRON |

|

2 |

SQ2 |

Photoelectric switch |

E32-D61 |

2 |

OMRON |

|

3 |

SQ3 |

Photoelectric switch |

RT318K/P-100.11 EE-5X673A |

1 |

OMRON |

|

4 |

PLC |

PLC |

VBO-28MR DVP-24ES00R2 |

1 |

KINCO |

|

5 |

VFD |

frequency converter |

VFD037EL43A |

1 |

Delta |

|

6 |

RP |

Potentiometer |

PV24YN20S |

1 |

Taiwan |

|

7 |

QS |

Power switch |

GLD11-63/04 63A |

1 |

Gree |

|

8 |

QF1,2 |

circuit breaker |

DZ108-20 5-8A |

3 |

Schneider Tianzheng |

|

9 |

QF3 |

circuit breaker |

GV2-M14 6-10A DZ108-201-1.5A |

3 |

Schneider |

|

10 |

QF6 |

circuit breaker |

DZ47-63.2P |

3 |

Schneider |

|

11 |

QF9 |

circuit breaker |

C65N IP 4A |

1 |

Schneider |

|

12 |

KM1 |

AC contactor |

LC1-D0910 |

|

Schneider |

|

13 |

QF10 |

circuit breaker |

3P 10A |

1 |

Schneider |

|

14 |

KA2,4 |

Intermediate relay |

MY2NJ24VDC 10A |

2 |

OMRON |

|

15 |

TC |

Transformer |

JBK5-150 380V/220 220VA 26V |

1 |

Tianzheng |

|

16 |

HL |

indicator light |

XB2BVM-4C |

1 |

Schneider |

|

17 |

SB1 |

Button switch |

ZB2BA3C+BZ101C green |

1 |

Schneider |

|

18 |

SB2 |

push-button switch |

ZB2BA4C+BZ101C red |

1 |

Schneider Schneider |

|

19 |

SB3 |

Button switch |

ZB2BA3C+BZ101C green |

1 |

Schneider |

|

20 |

SB4 |

Button switch |

ZB2BA4C+BZ101C red |

1 |

Schneider |

|

21 |

SB5 |

Button switch |

ZB2BA3C+BZ101C green |

1 |

Schneider |

|

22 |

SB6 |

Button switch |

ZB2BA4C+BZ101C red |

1 |

Schneider |

|

23 |

SB7 |

Button switch |

ZB2BA3C+BZ101C green |

1 |

Schneider |

|

24 |

SB8 |

Button switch |

ZB2BA4C+BZ101C red |

1 |

Schneider |

|

25 |

SB9 |

Button switch |

ZB2BA5C+BZ101C yellow |

1 |

Schneider |

|

26 |

M1 |

Main motor |

UABP100L2-4P-50H2-3KW 3.0KW B3-Left |

1 |

CDQC |

|

27 |

FM |

Fun |

TA11025SL-2 220V |

1 |

|

|

28 |

M3 |

Whirlpool pump |

HG-1100S 1100KW 380V 2.4A |

1 |

TECO |

|

29 |

M3 |

Whirlpool pump |

HG-2200S 2200KW 380V 2.4A |

1 |

TECO |

|

30 |

M2 |

vacuum pump |

3KW 6.8A ZYB80A-1 |

1 |

Jinma |

|

31 |

M4 |

Roller motor |

CJ-18 380V 90W |

1 |

Jingyan |

|

32 |

|

Touch screen |

|

1 |

KINCO |

|

33 |

SA-5.7A7B |

Contents |

|

1 |

HITECH |

|

34 |

|

Harmonic filter |

|

1 |

CTKM |

|

35 |

|

Chain |

|

|

RENOLDL |

|

36 |

|

DC |

120 |

|

Schneider |

|

37 |

|

Servo motor |

0.75 |

1 |

KINCO |

|

38 |

|

Feed belt |

|

|

NITTA |

|

|

|

Suction belt |

|

|

RAPPLON |

|

|

|

Collection belt |

|

|

RAPPLON |

|

|

|

Rotary encoder |

|

|

MARTIN |

Product detail pictures:

Related Product Guide:

Dedicated to strict high-quality management and considerate shopper company, our experienced team associates are normally available to discuss your requirements and ensure full shopper gratification for China New Product Window Pasting Machine – STC-650 Window Patching Machine – Eureka , The product will supply to all over the world, such as: India, Pretoria, Sri Lanka, Since our establishment, we keep on improving our products and customer service. We are able to provide you with a wide range of high quality hair products at competitive prices. Also we can produce different hair products according to your samples. We insist on high quality and reasonable price. Except this, we provide best OEM service. We warmly welcome OEM orders and customers all over the world to cooperate with us for mutual development in the future.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.