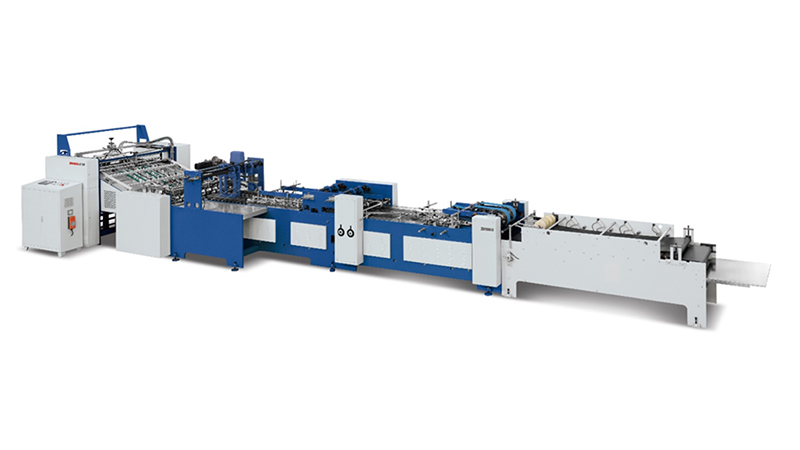

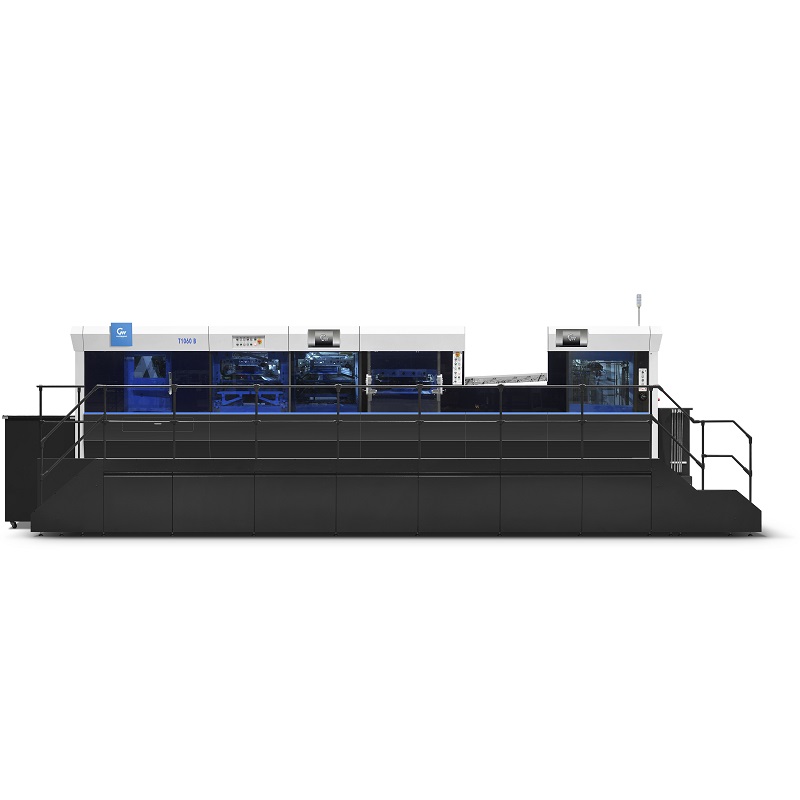

China wholesale Flatbed Diecut - GUOWANG T-1060BF DIE-CUTTING MACHINE WITH BLANKING – Eureka

China wholesale Flatbed Diecut - GUOWANG T-1060BF DIE-CUTTING MACHINE WITH BLANKING – Eureka Detail:

1. FEEDER

High quality MABEG feeder head imported from Germany(option), 4 pick-up suckers and 4 forward suckers, ensure stable and fast feeding.

Pre-loading device to feed paper without stopping the machine, maximum stack height 1600mm

Pre-loading tracks help the operator push paper stack to feeding position accurately and conveniently.

Side lays can be adjusted to fit different paper.

Paper transferred to the front lay will slow down to ensure accurate positioning.

Transferring plate is stainless steel imported from Germany to make the paper conveying smooth and fast.

2. DIE-CUTTING UNIT

Precise and stable control of die cutting pressure, controlled by FUJI servo motor

Easy to use graphic interface by 19 inch touch screen with precision up to 0.01mm.

Die-cutting chase and plate are locked by pneumatic cylinder from Japanese SMC, with misplace sensors to avoid damage caused by human factors.

Die-cutting chase adopts the center-line system for fast positioning , so that the operator don’t need to consider the left-right position of the die board.

Die-cutting boards of non-standard size can also be installed by using auxiliary tools to facilitate applicability of customers’ cutting boards from different models .

Gripper bar, of special aluminum alloy , the surface after oxidation treatmentadopts double-cam opening method to release the paper during running. It can reduce the inertia of paper to collect the thin paper in order easily.

3. STRIPPING UNIT

Pneumatic lifting stripping chase

Center-line system and quick-lock device for stripping board to achieve quick job changing

Stripping chase position memorization.

4. BLANKING UNIT

Center-line system and quick-lock device for blanking board to achieve quick job changing

One button for sample sheet taking, easier for inspection of quality.

Intelligent operation from monitor to choose different mode of inserting sheet.

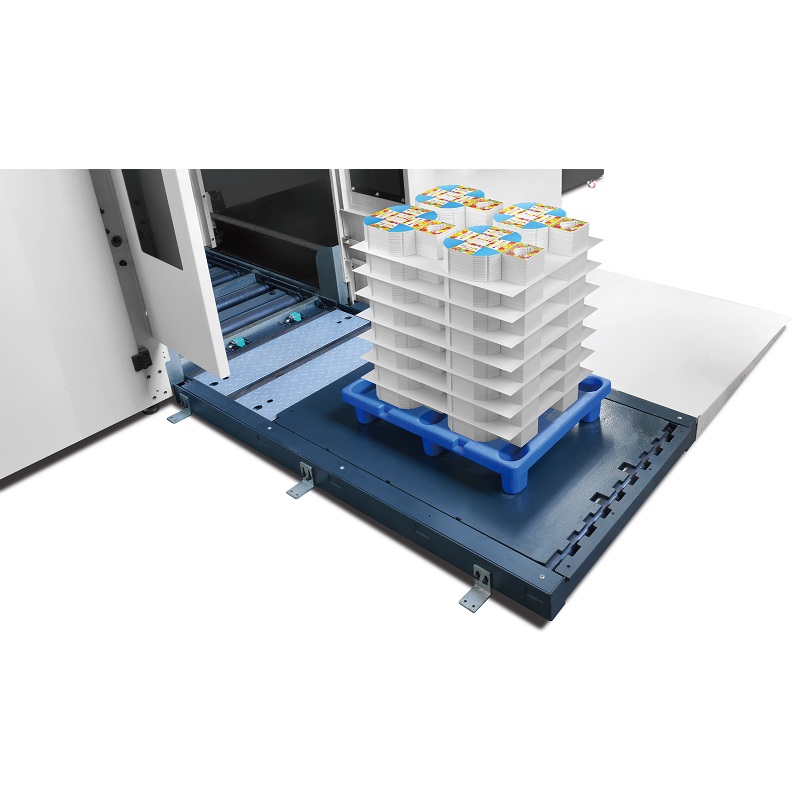

5. DELIVERY UNIT

Non-stop delivery unit.a

Automatic paper pile transfer, transfer working pallet to delivery unit, then place the empty pallet to wait for proceeding, can reduce manual intervention and ensures non-stop delivery.

6. WORK FLOW

| Maximum paper size | 1060*760 | mm |

| Minimum paper size | 400*350 | mm |

| Maximum cutting size | 1060*745 | mm |

| Maximum Die-cutting plate size | 1075*765 | mm |

| Die-cutting plate thickness | 4+1 | mm |

| Cutting rule height | 23.8 | mm |

| First die-cutting rule | 13 | mm |

| Gripper margin | 7-17 | mm |

| Cardboard spec | 90-2000 | gsm |

| Cardboard thickness | 0.1-3 | mm |

| Corrugated spec | ≤4 | mm |

| Maximum working pressure | 350 | t |

| Maximum die-cutting speed | 7500 | S/H |

| Feeding board height (incl. pallet) | 1800 | mm |

| Non-stop feeding height(incl. pallet) | 1300 | mm |

| Delivery height(incl. pallet) | 1400 | mm |

| Main motor power | 18 | kw |

| Whole machine power | 24 | kw |

| Voltage | 600V 60Hz 3ph | v |

| Cable thickness | 16 | mm² |

| Air pressure requirement | 6-8 | bar |

| Air consumption | 300 | L/Min |

| Configurations | Country of origin |

| Feeding unit | |

| Jet-feeding Mode | |

| Feeder head | German Mabeg |

| Pre-loading device, Non-stop feeding | |

| Front & side lay photocell induction | |

| Light guard protecting device | |

| Vacuum pump | German Becker |

| Pull/push switch type side guide | |

| Die-cutting unit | |

| Die chase | German FESTO |

| Centre line alignment system | |

| Gripper mode adopt latest double cam tech | Japan |

| Pre-stretched high quality chain | German |

| Torque limiter and index gear box drive | Japan Sankyo |

| Cutting plate pneumatic ejecting system | |

| Automatic lubrication and cooling | |

| Automatic chain lubrication system | |

| Main motor | German SIEMENS |

| Paper miss detector | German LEUZE |

| Stripping unit | |

| 3-way stripping structure | |

| Centre line alignment system | |

| Pneumatic lock device | |

| Quick lock system | |

| Bottom feeder | |

| Blanking delivery unit | |

| Non-stop delivery | |

| Delivery motor | German NORD |

| Finishing product delivery motor | German NORD |

| Waste collecting motor | Shanghai |

| Secondary delivery motor | German NORD |

| Automatic delivery stack switch function | |

| Automatic feeding device | German FESTO |

| Feeding air sucker motor | |

| Electronic parts | |

| High quality electrical components | EATON/OMRON/SCHNEIDER |

| Safety controller | German PILZ safety module |

| Main monitor | 19 inch AMT |

| Secondary monitor | 19 inch AMT |

| Inverter | SCHNEIDER/OMRON |

| Sensor | LEUZE/OMRON/SCHNEIDER |

| Switch | German MOELLER |

| Low-voltage distribution | German MOELLER |

Product detail pictures:

Related Product Guide:

We've been committed to offering easy,time-saving and money-saving one-stop purchasing service of consumer for China wholesale Flatbed Diecut - GUOWANG T-1060BF DIE-CUTTING MACHINE WITH BLANKING – Eureka , The product will supply to all over the world, such as: Albania, Netherlands, Indonesia, Each year, many of our customers would visit our company and achieve great business advancements working with us. We sincerely welcome you to visit us at any time and together we will prevail to a greater success in the hair industry.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.