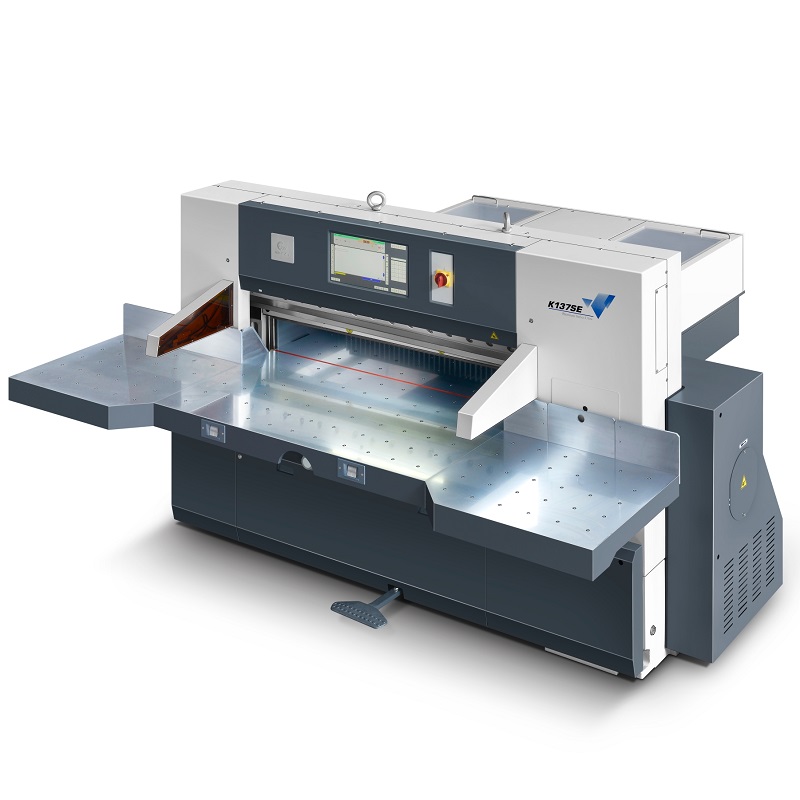

Chinese Professional Royal Paper Cutter - Periphery equipments for high speed cutting line – Eureka

Chinese Professional Royal Paper Cutter - Periphery equipments for high speed cutting line – Eureka Detail:

Our GW-S computer control unit with 19” color touch screen for automating backgauge movement is the most user-friendly system in the industry,50000+ programs for job saving.

GW-S series are all equipped with CIP4 JDF capability and are all networkable with no additional hardware or software required.

Cutting power is provided by a hydraulic clutch and time-tested worm gear design

Cushion contact clamping eliminates pile disturbance.

High-speed steel knives offer extended durability.

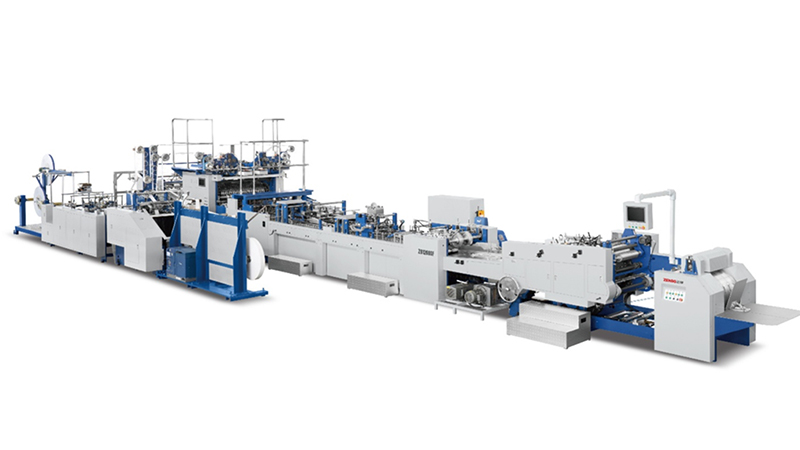

Front feeding cutting line (IPT-2+GW-137S+LG-2)

Front feeding cutting line (IPT-2+GW-137S+LG-2)

Rear feeding cutting line (Q-2+GW-137S+SU-2) L line

IPT-2/IPT-4

INTELLIGENT LOADER

Developed independently by GW Group in the Year 2013,the brand new product,

intelligent loader is a replacement of traditional products of the same type ,

filling the technology gap domestic and abroad ;

it improves its working efficiency ,operation and safety ,

becomes one of the most perfect equipments in automatic cutting system .

1.the machine serves for automating the pile taking

and transporting onto the working table of high speed cutter .

2.The pile loading is fast , safe and precise which reduces labor intensity to a large degree .

3.With laser position detecting device, machine can detect paper position accurately.

4.With flexible anti-collision safety bar, machine can stop immediately when it is touched.

5 The pneumatic gripper runs stable and softly for perfect pile loading and jogging.

6. Operation is convenient with 10.4 touch monitor.

7.Machine adopts German Nord Motor with stable running and low noise.

LG-2/LG-4

UNLOADER

1.Infrared Bar can detect paper position accurately to ensure pile can stack in order.

2.Operation is convenient with 10.4 touch screen.

3.Anti-collision flexible safety bar can avoid machine from hurting itself

and body during machine running.

4.Pneumatic gripper can avoid paper corner from hitting by out force.

5.Machine adopt German Nord motor with stable running and low noice.

Machine has the function including left alignment, middle alignment,

right alignment, free flapping and so on.

JPA-2

JOGGER

Jogger is the special machine for materials ready for cut,

it will help exhaust the air to ensure the continuity

of the cutting material output was improved greatly.

Greatly improve the accuracy of cutting,

laying good foundation for the final quality of the finished product.

LT-1/LT-2/LT-3/LT-4

LIFTER

The machine can move pile up and down with convenient operation.

Operator can transfer material to jogger or guillotine at convenient height

which can rise cutting efficiency by 10%.

Q-2/Q-4

ECONOMICAL INTELLIGENT LOADER

SU-2/SU-4

SMART

UNLOADER

Starting from November 2014, the group company started the third workshop equipment technology upgrade project, introducing CNC from world-renowned brands such as Japan’s Ikegai, Japan’s Mazak, Japan’s Mori Seiki, Switzerland’s Starrag, and Italy’s Mandeli. Processing machine.

Japan Okuma OKUMA-MCR-A5C gantry type 5-sided machining center has excellent processing efficiency of large parts, and is equipped with various extended processing systems to complete 5-sided, curved surface and other three-dimensional processing. The stable machine tool mechanism can maintain its high rigidity, smooth mobility and high precision for a long time. Guowang Group die-cutting machine, paper cutter base, body and other large parts are completed on this machine. The ACC tool change system can easily perform complex machining conversion from powerful cutting to fine boring cycles.

Ikegai NB130T

The high stability and high rigidity of Ikegai NB130T make high-precision boring the advantage of this machining center. Guowang has changed the conventional method of horizontal processing, processing the workpiece standing up, completely making the position in a free state, and avoiding the deformation caused by the workpiece reversed. The standing machining and the rotary table can complete the machining of all sides of the workpiece at one time, which perfectly guarantees the accuracy of the dimensions of the workpiece. It is also equipped with the world’s most advanced machining tools, and every detail is meticulously crafted. ,Strive for perfection.

Mazak

The Mazak machine tool is a CNC machining center with a six-station rotary table. Multiple workpieces can be automatically processed at the same time, eliminating the need to waste clamping time and improving work efficiency to a certain extent. Mainly used for processing the feet of paper cutters. For the machining of the machine feet, automatic indexing completes the precise machining of each surface, achieving 100% accuracy. It effectively ensures that the internal hydraulic system of the machine foot is in a vertical and horizontal state during work, and also ensures that the resistance of the workpiece is reduced when it is running, and it runs smoothly.

Starrag

Starrag has four-axis and five-axis milling technology for complex parts, whether it is engine housing, gearbox housing, cylinder head, or impellers, blisks, blades and aircraft structural parts. It can easily complete the combined processing of various connecting rods, toggle levers and other precision transmission parts of Guowang. The tool change system with up to 200 tools is fully adapted to the complex processing of various parts.

Japan’s Mori Seiki SH-63 Horizontal Boring and Milling Machining Center

Japan’s Mori Seiki SH-63 horizontal boring and milling machining center, with a double-station interchangeable rotary table, is a powerful tool for small and medium-sized complex parts. It can complete the processing of 5 faces at a time, and only needs 2 seconds to change the tool. , Has a place in the world machine tool industry. Through the expansion of automated devices such as APC and unmanned systems such as linear pallet storage tanks, high operating rates can be achieved. It is suitable for high-efficiency production and unmanned operation of batch parts.

Gaoming KAOMING

Gaoming gantry machining center. It mainly processes the most basic part of the paper cutter-the flat plate. The accuracy of the flat plate directly affects the accuracy of the cut object. The plane of the flat plate is the basis of accuracy. It adopts a free-style clamping process, and under the influence of gravity, it is infinitely close to the horizontal plane. When the reverse surface is processed, it can be used as a reference plane to effectively ensure the accuracy of all dimensions.

We use the strength of this processing cluster to ensure the quality of Guowang. Our goal is simple: use good equipment to make high-quality products.

Product detail pictures:

Related Product Guide:

Dedicated to strict quality management and thoughtful client services, our experienced staff customers are generally available to discuss your demands and guarantee full client pleasure for Chinese Professional Royal Paper Cutter - Periphery equipments for high speed cutting line – Eureka , The product will supply to all over the world, such as: Jamaica, Angola, Sacramento, Why we can do these? Because: A, We are honest and reliable. Our products have high quality, attractive price, sufficient supply capacity and perfect service. B, Our geographical position has a big advantage . C, Various types: Welcome your inquiry, It will be highly appreciated.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.