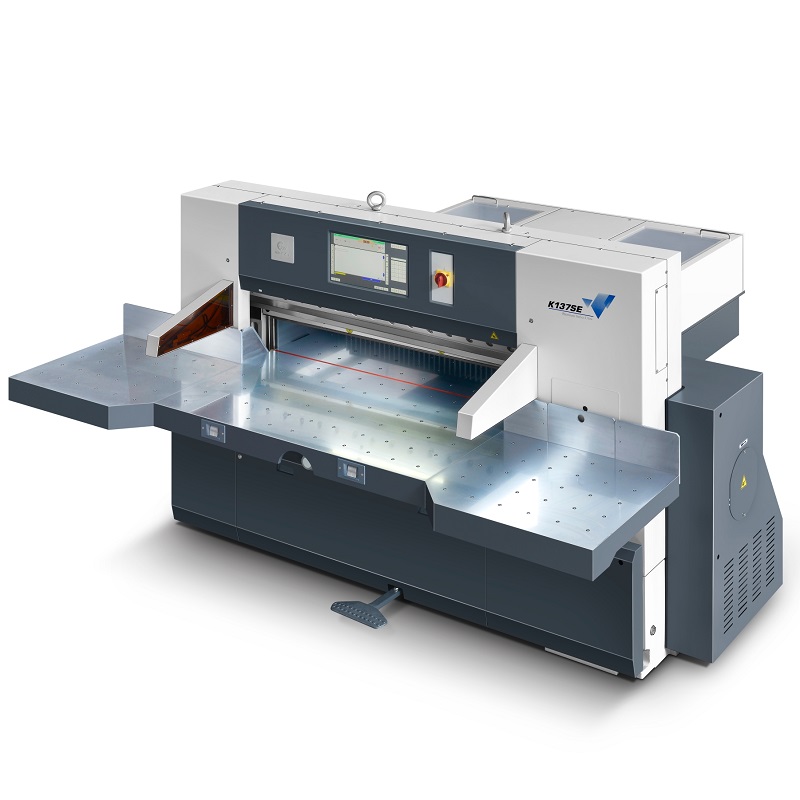

Chinese wholesale High Speed Sheet Cutter - GW PRECISION TWIN KNIFE SHEETER D150/D170/D190 – Eureka

Chinese wholesale High Speed Sheet Cutter - GW PRECISION TWIN KNIFE SHEETER D150/D170/D190 – Eureka Detail:

According to GW product’s technics, The machine are mainly used for paper sheeting in Paper Mill, Printing House and etc, mainly process including: Unwinding—Cutting—Conveying—Collecting,.

1.19″ and 10.4″ dual touch screen at cutting unit and delivery unit controls are used to set and display sheet size, count, cut speed, delivery overlap, and more. The touch screen controls work in conjunction with a Siemens PLC.

2.The high-speed belt is driven by British CT high-power servo to ensure smooth paper output.The pneumatic waste ejecting structure remove waste paper and improves the convenience of operation. The gas spring belt tensioning device ensures that each belt can run smoothly.

3.The TWIN KNIFE cutting unit has a synchronic rotary cutting knife like scissors on the material to make a smooth and accurate cutting for paper from 150gsm and up to 1000gsm.The knife roller and paper pulling roller are separately driven by 2 CT high power servo from UK, adopt a gap-free gear structure design, and with GW’s 5 axis high accuracy CNC to machine the main stand in one piece. to effectively eliminate the shaking gap of the two knives, ensuring the life of the blade and cutting accuracy. which guarantees the stability of the tool body during high-speed operation.

4.Three sets of heavy duty pneumatic slitters ensure stable and clean slitting. Electrical driven automatic cutting width adjustment.(*Option).

5.Dual shaftless back stands with web tension controls and pneumatic brake units are standard.

6.The spray gear lubrication system ensures the gears are fully lubricated during the entireoperation. Effectively extend the service life of the machine.

| Model | GW D150/D170/D190 |

| Type of cutting | Twin knife, Top blade and bottom blade rotary cutting |

| Paper weight range | 150-1000 GSM |

| Reel stand load capacity: | 2 tons |

| Reel diameter | Max 1800mm (71″) |

| Cutting Width | Max 1500/1700/1900mm (66.9″) |

| Cut off length range | Min.400-Max.1700 mm |

| Num. of rolls cutting | 2 rolls |

| Cutting accuracy | ±0.15mm |

| Max. Speed of cutting | 400cuts/min |

| Max. Cutting speed | 300m/min |

| Delivery height | 1700mm(incl.pallet) |

| Voltage | AC380V/220Vx50Hz 3ph |

| Main motor power: | 64kw |

| Total power | 98kw |

| Output | The real output depends on the material, and the weight of the paper, and right operate process |

| 1. | Dual position shaftless pivoting arm unwind stand |

| 2. | Air cooling pneumatic disc brake |

| 3. | Auto tension based on reel diameter |

| 4. | Servo controlled decurler system |

| 5. | EPC web guiding |

| 6. | Twin helical knife cylinders |

| 7. | Three sets of Pneumatic Slitters |

| 8. | Anti-Static Bar |

| 9. | Out feed and overlapping section |

| 10. | Hydraulic delivery unit 1700mm |

| 11. | Auto counting and tap inserter |

| 12. | Dual touch screen |

| 13. | JIJIN PLC, UK CT Servo Driver, Schneider inverter, imported electrical components |

| 14. | Ejecting gate |

1. Dual position shaftless pivoting arm unwind stand

Dual position shaftless pivoting arm unwind stand with in-floor track and trolley system.

2. Air cooling pneumatic disc brake

Air cooled pneumatic controlled disc brakes on each arm.

3. Auto tension based on reel diameter

Auto tension controller gives you fine control on the tension especially for small reel.

4. EPC web guiding

EPC sensor coupled with an independent “swing frame” allows for minimum edge trim of the web, and strict control of the web edge throughout the reel from start to finish.

5. Servo controlled decurler system

Servo controlled decurler system can automatically detect the diameter of paper and adjust the recurve power, the coefficient can also be set by different material gsm, and the recurve power will follow the set material and diameter.

6. Twin Knife driven by servo motor

a.The twin helical knife ensures the very sharp and clean cutting edge with high accuracy

b.The blade is made of special alloy st eel SKH.9 with long life and easy maintenance.Twin knife roller and paper pulling roller are driven by separate servo motor.

7. Three sets of Pneumatic Slitters

Heavy duty pneumatic slitters ensure stable and clean slitting.

9. Out feed and overlapping section

a.Fully synchronized speed between high speed outfeeding and overlap tape section to maintain a proper shingle.

b.Overlapping unit with adjustable overlapping value and jam-stop sensor. Single sheet outlet can be set.

12. Siemens touch screen

Length of cut, quantity, machine speed, cut speed can be displayed and set via touch screen.

8. Anti-Static Bar

10. Hydraulic delivery unit

14. Ejecting gate

11. Auto counting and tap inserte

13. Self designed PLC, Schneider inverter, CT Servo motor, FUJI servo driver

| 1. | Splicer |

| 2. | Mechanical-expanding chuck |

| 3. | Automatic cutting width adjustment |

| 4. | Automatic pallet change |

| 5. | Delivery top belt |

| 6. | Non-stop stacker |

| 7. | Cursor tracking |

| 8. | Redundant safety control and interlock safety system |

1.Splicer

2. Mechanical-expanding chuck

3. Automatic cutting width adjustment

4. Automatic pallet change

5.Delivery Top Belt

6.Non-stop stacker

8. Redundant safety control and interlock safety system

|

PART NAME |

BRAND |

COUNTRY OF ORIGIN |

|

PLC |

JIJIN |

CHINA |

|

Magnetic switch (2 wires) |

Festo |

GERMANY |

|

Proximity switch (NPN) |

Omron |

JAPAN |

|

Solid State Relay (40A) |

CARLO |

Switzerland |

|

Thermo relay |

Eaton |

USA |

|

LED module |

Eaton |

USA |

|

Relay socket |

Omron |

JAPAN |

|

Intermediate relay |

IDEC |

JAPAN |

|

AC/DC contactor |

Eaton |

USA |

|

Hollow reducer |

JIE |

CHINA |

|

Circuit breaker |

Eaton |

USA |

|

Motor protector |

Eaton |

USA |

|

Position switch |

Schneider Electric |

FRANCE |

|

Button (self lock) |

Eaton |

USA |

|

Select switch |

Eaton |

USA |

|

Servo controller |

CT |

UK |

|

Seervo driver |

FUJI |

JAPAN |

|

Servo controller |

CT |

UK |

|

Frequency converter |

Schneider Electric |

FRANCE |

|

Servo driver 0.4kw |

FUJI |

JAPAN |

|

Rotary encoder |

Omron |

JAPAN |

|

Switching power supply |

MW |

TAIWAN.CHINA |

|

Connection terminal |

Weidmüller |

GERMANY |

|

AC contactor |

ABB |

USA |

|

Circuit breaker |

ABB |

USA |

|

Photoelectric sensor |

Leuze |

GERMANY |

|

Hydraulic pressure detector switch |

PAKU |

|

|

Servo motor (CT 18.5kw) |

CT |

UK |

|

Servo motor (CT 64kw) |

CT |

UK |

|

Servo motor (CT 7.5kw) |

CT |

|

|

Centrifugal medium-pressure blower (0.75kw, 2800rpm) |

POPULA |

CHINA |

Through the co-operation with top-level partner in the world, Guowang Group (GW) owns Joint venture company with Germany partner and KOMORI global OEM project. Based on the German and Japanese advanced technology and more than 25 years experience, GW continually offer the best and highest efficient post-press solution.

GW adopts the advanced production solution and 5S management standard, from R&D, purchase, machining, assembling and inspection, every process strictly follow the highest standard.

GW invest a lot in the CNC, import DMG, INNSE- BERADI, PAMA, STARRAG, TOSHIBA, OKUMA, MAZAK, MITSUBISHI etc. from all over the world. Only because pursues the high quality. The strong CNC team is the firm guaranty of the quality of your products. In GW, you will feel the “high efficient and high precision”

Product detail pictures:

Related Product Guide:

We are also specializing in improving the things management and QC method in order that we could retain terrific edge inside the fiercely-competitive small business for Chinese wholesale High Speed Sheet Cutter - GW PRECISION TWIN KNIFE SHEETER D150/D170/D190 – Eureka , The product will supply to all over the world, such as: Kuala Lumpur, Guinea, Greece, With excellent products, high quality service and sincere attitude of service, we ensure customer satisfaction and help customers create value for mutual benefit and create a win-win situation. Welcome customers all over the world to contact us or visit our company. We will satisfy you with our professional service!

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!