Corrugated

-

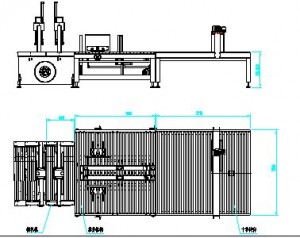

Automatic PE Bundling Machine JDB-1300B-T

Automatic PE Bundling Machine

8-16 bales per minute.

Max Bundle Size : 1300*1200*250mm

Max Bundle Size : 430*350*50mm

-

3-Ply Corrugated Board Production Line

Machine type: 3-ply corrugated production line incl. corrugated making slitting and cutting

Working width: 1400-2200mm Flute type: A,C,B,E

Top paper:100—250g/m2 core paper:100–250g/m2

Corrugated paper:100—150g/m2

Running power consumption: Approx.80kw

Land occupation: Around 52m×12m×5m

-

5-Ply Corrugated Board Production Line

Machine type: 5-ply corrugated production line incl. corrugated making slitting and cutting

Working width: 1800mm Flute type: A,C,B,E

Top paper index:100- 180gsm Core paper index 80-160gsm

In paper index 90-160gsm

Running power consumption: Approx.80kw

Land occupation: Around 52m×12m×5m

-

SAIOB-Vacuum suction Flexo Printing & Slotting &Die cutting & Glue in Line

Max. speed 280sheets/min. Max Feeding size(mm) 2500 x 1170.

Paper thickness:2-10mm

Touch screen and servo system control operation. Each part is controlled by PLC and adjusted by servo motor. One-key positioning, automatic reset, memory reset and other functions.

The light alloy material of the rollers is sprayed with wear-resistant ceramics, and the differential rollers are used for vacuum adsorption and transmission.

Able to implement remote maintenance and connect to the entire plant management system.

-

VISTEN Automatic Flexo High Speed printing &slotting & glue in line

Name Amount Feeding unit( Lead Edge Feeder ) 1 Printer unit( Steel anilox roller +rubber roller) 6 Slotting unit 1 Auto gluer 1 Automatic Flexo Printing & Slotter & Die cutter Machine of VISTEN Functional configuration and technical parameters. I. Computer operation control unit 1.Memory to zero: the machine wipe version or a small amount of plate changing in the course of their work for open machine, after the close of the machine can automatically restore t... -

Full-servo vacuum suction high speed flexo Printing& Slotter of ORTIE-II

Feeding unit( Lead Edge Feeder ) 1 Printer unit( Ceramic anilox roller +Blade) 3 Slotter unit 1 Auto Gluer unit 1 Full-servo vacuum suction High speed Flexo printing &Slotter&Gluer Of ORITE-II(Fixed) I.Computer-controlled operation unit 1, the machine adopts computer control, the Japan servo driver; 2, each unit is equipped with a man-machine interface, easy to operate, accurate adjustment, after the completion of the input can be directly intelligent nearest homin... -

XT-D Series high-speed flexo printing slotting stacking machine

High speed flexo printing slotting and stacking

Sheet size: 1270×2600

Working speed:0-180 sheets/min

-

Automatic PP Strapping Machine for Corrugated YS-LX-500D (in line,double strap heads,5mm width tape)

Automatic PP corrugated strapping with double strap heads, 15pcs/min for 1 strap, 10 pcs/min for 2 straps

-

2-Ply Single Facer Corrugated Board Production Line

Machine type: 2-ply corrugated production line incl. single facer making slitting and cutting

Working width: 1400-2200mm Flute type: A,C,B,E

Single facer Facial tissue:100—250g/m² core paper:100–180g/m²

Running power consumption: Approx.30kw

Land occupation: Around 30m×11m×5m

-

Automatic Folder Gluer and Stitcher for corrugated box (JHXDX-2600B2-2)

Suitable for folding and gluing and stitching for A,B,C,AB Flute

Max. Stitching speed: 1050 nails/min

Max. Size: 2500*900mm Min. Size: 680*300mm

Fast carton forming speed and fine effect. Eight suctions at the leading edge feeder are adjustable for accurate feeding. Strengthened folding section, and the size of the mouth is well controlled, reducing waste. Arm sorting function for fast job changing and neat sheet. Main power driven by servo motor. PLC& human-machine interface for easy operation.

-

Automatic Folder Gluer for corrugated box(JHX-2600B2-2)

Suitable for A.B.C.AB. flute,3-ply, 5-plc corrugated sheets folding gluing

Max. Size: 2500*900mm

Min. Size: 680*300mm

Fast carton forming speed and fine effect. Eight suctions at the leading edge feeder are adjustable for accurate feeding. Strengthened folding section, and the size of the mouth is well controlled, reducing waste. Arm sorting function for fast job changing and neat sheet. Main power driven by servo motor. PLC& human-machine interface for easy operation. Stepless speed regulation, secondary correction.