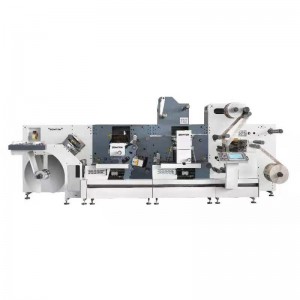

Dragon 320 Flat Bed Die Cutting Machine

|

Model |

DRAGON-320 |

|

Max speed |

120M/MIN |

|

Max effective paper width |

330MM |

|

Silk screen printing speed |

60-100 times / min |

|

Accuracy of adhesive cutting Accuracy of IML cutting |

±0.15mm ±0.25mm |

|

Registration |

Sensor |

|

Max hot foil dia |

300mm |

|

Hot foil feeding direction |

0 dgree/90 dgree |

|

Foil jump adjustment |

Support by servo |

|

Accuracy of foil register |

±0.15mm |

|

Heat range |

0-200 dgree |

|

Semi rotary flexo area 144 Z |

400mm*320mm |

|

Semi rotary die cutting area 144Z |

400*320 MM |

|

Air supply |

0.4-0.6pa |

|

Dimension |

11275*1510*1820MM |

|

weight |

8000 kgs |

| Servo driver | Panasonic Japan (including unwinding /feeding / rewinding / flexo /die cutting) totallu10 pcs |

| Control system | Trio UK |

| PLC | Panasonic Japan |

| Transducer | Panasonic Japan |

| Contactor | Schneider France |

| Air switch | Schneider France |

| Value | Schneider France |

| Touch screen | Pingtong Taiwan |

| Web guide | BST Germany |

| Button | Schneider France |

|

No. |

Product |

|

1 |

DRAGON -320 converting production line include: The base configuration: Unwinding + flat bed hot stamping unit + Rewinder |

|

2 |

Semi rotary flexo unit |

|

3 |

Silk screen unit |

|

4 |

Semi rotary flexo unit |

|

5 |

Flat bed hot foil unit |

|

6 |

Flat bed die cutting unit |

|

7 |

Semi rotary die cutting unit |