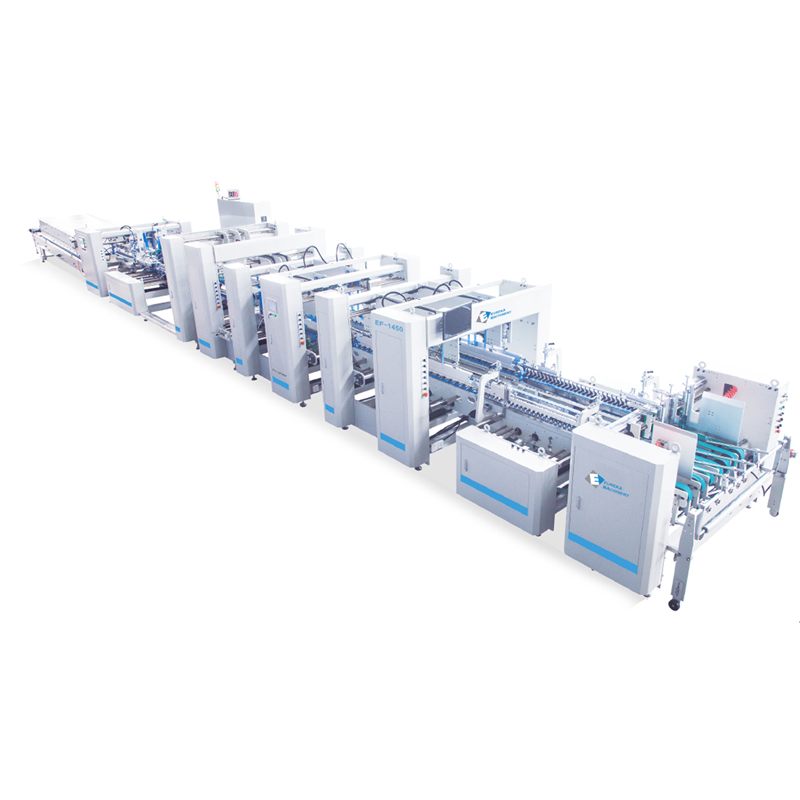

EF series large format (1200-3200) Automatic Folder Gluer

1)Feeding section:

Folder gluer Feeding section is driven by independent AC motor with controller, widened belts, knurl rollers and vibrator for smooth and accurate speed adjustment. The left and right thick metal boards can be easily moved according to the paper width; three feeding blades can adjust the feeding size according to the paper length. The suction belts by vacuum pump cooperating with the motor, ensures the feeding continuous and stable. Stacking height up to 400mm. Vibration Can operate by remote controller at any position of the machine.

2)Paper side alignment section:

The alignment section of folder gluer is three-carrier structure, using push-side way for regulation, guides paper to accurate position with stable running.

3)Pre-Creasing section (*Option)

Independently driven scoring section, mounted after alignment section, before folding, to deepen scoring lines which are shallow and improve folding and gluing quality.

4) Pre-folding section (*PC)

The special design can pre-fold the first folding line at 180 degrees and the third line at 135 degrees that can makes box easier to open on our folder gluer

5)Crash lock bottom section:

Crasg lock bottom section of our EF series folding gluing machine is three-carrier structure, with the upper-belt transmission, wider lower belts, ensures stable and smooth paper transport. Completed hook devices with accessories to fit wide range of regular and irregular boxes. Upper belt carriers can be lifted by pneumatic device to accommodate different thickness material.

Lower gluing devices (at left and right) of large capacity, adjustable glue amount with various thickness wheels, simple maintenance.

6)4/6 corner section(*PCW):

4/6 corner folding system with intelligent servo-motor technology. It allows accurate folding of all back flaps by means of hooks installed in two independent shafts controlled electronically.

Servo system and parts for 4/6 corner box

Yasakawa servo system with motion module ensure high speed response to match high speed request

Independent touch screen facilitate the adjustment and make operation more flexible on our folder gluer

7)Final-folding :

Three-carrier structure, special extra-long folding module to ensure paper board have enough space. Left and right outward folding belts are driven by independent motors with variable speed control for straight folding and to assist to avoid “fish-tail” phenomenon on folder gluer.

8)Trombone:

Independent driving. Upper and lower belts can be moved forward and backward for easier adjustment; Quick switch between different modes of stacking; Automatic belt tension adjustment; Jogging device for accurate closing of crash lock bottom boxes, Auto counter with kicker or inkjet to mark; Paper jam detector is equipped with pneumatic roller to press boxes to be perfect status.

9)Pressing conveyor section:

With upper and lower independent driving structure, it’s convenient to adjust upper conveyor to fit different box length. Soft and smooth belt avoid scratching on the box. Optional sponge belt to strengthen pressing effect. Pneumatic system ensure well balanced and perfect pressing quality. The conveyor speed can be synchronized with the main machine for automatic follow-up by optical sensor as well as be adjusted by manual.

Model EF series folder gluer machines are multi-functional, mainly for medium-size packages of 300g -800g cardboard, 1mm-10mm corrugated, E,C,B,A,AB,EB five facer corrugated material, can produce 2/4 folds, crash lock bottom, 4/6 corner box, printed slotted carton. The separated driving and functional module’s structure provides powerful output and simple, convenient operation by graphic HMI, PLC control, online-diagnosis, multi-function remote controller. The transmission with independent motor driving creates smooth and quiet running. The carrier upper belts under stable and easy pressure-control are achieved by independent pneumatic devices. Equipped with high-performance servo motors for definite sections, this series machines can satisfy the demands of highly stable and efficient production. The folder gluer are produced according to European CE standards.

- Modulation structure design can upgrade machine functions according to customer’s requirements.

- The whole folder gluer driving way adopts independent synchronized motor driving.

- Specially equipped with paper side alignment section.

- Strengthen, broadened upper and lower belt driving, suitable for corrugated cartons.

- The whole machine carrier’s adjustment is motorized for easy commissioning.

- Upper and lower carrier movement adopts linear guide-rail system, to ensure the mechanical accuracy.

- Humanized design for easy installation and operation, one hexagon spanner can adjust the whole machine.

- Final folding, trombone sections with independent motors for adjustment, and pressing conveyor section with squaring device, can effectively avoid the “fish-tail” phenomenon of corrugated products.

- Pressing conveyor section adopts pneumatic cylinders system, is easy to adjust pressure, and make the products can be tight-stick effectively.

- Touch screen, graphic HMI, remote controller with multi-function for convenient operation.

A.Technical data:

|

Performance/models |

1200 |

1450 |

1700 |

2100 |

2800 |

3200 |

|

Max. Sheet size(mm) |

1200*1300 |

1450*1300 |

1700*1300 |

2100*1300 |

2800*1300 |

3200*1300 |

|

Min. Sheet size(mm) |

380*150 |

420*150 |

520*150 |

|||

|

Applicable paper |

Cardboard 300g-800g corrugated paper F、E、C、B、A、EB、AB |

|||||

|

Max. Belt speed |

240m/min. |

240m/min |

||||

|

Machine length |

18000mm |

22000mm |

||||

|

Machine width |

1850mm |

2700mm |

2900mm |

3600mm |

4200mm |

4600mm |

|

Total power |

35KW |

42KW |

45KW |

|||

|

Max. Air displacement |

0.7m³/min |

|||||

|

Total weight |

10500kg |

14500kg |

15000kg |

16000kg |

16500kg |

17000kg |

Basic box size range (mm):

Remark: can customize for the boxes of special sizes

EF:1200/1450/1700/2100/2800/3200

Note for model: AC—with crash lock bottom section; PC—with pre-folding, crash lock bottom sections; PCW--with pre-folding, crash lock bottom, 4/6 corner box sections

|

No. |

Configuration List | Remark |

|

1 |

4/6 Corner box device by Yaskawa servo | For PCW |

|

2 |

Motorized adjustment | Standard |

|

3 |

Pre-folding Unit | For PC |

|

4 |

Motorized adjustment with Memory function | Option |

|

5 |

Pre-Creasing unit | Option |

|

6 |

Jogger at trombone | Standard |

|

7 |

LED panel display | Option |

|

8 |

90 degree turning device | Option |

|

9 |

Pneumatic squaring device at conveyor | Option |

|

10 |

NSK Up pressing bearing | Option |

|

11 |

Upper glue tank | Option |

|

12 |

Servo driven trombone | Standard |

|

13 |

Mitsubishi PLC | Option |

|

14 |

Transformer | Option |

Machine doesn’t include cold glue spray system and inspection system, you need to choose from these suppliers, we will make offer according to you combination

|

1 |

KQ 3 glue gun with high pressure pump(1:9) | Option |

|

2 |

KQ 3 glue gun with high pressure pump(1:6) | Option |

|

3 |

HHS cold gluing system | Option |

|

4 |

Gluing inspection | Option |

|

5 |

Other inspection | Option |

|

6 |

Plasma system with 3 guns | Option |

|

7 |

KQ Application of adhesive label | Option |

1.

Main components brand and data

|

Out Source list |

|||

|

Name |

Brand |

Place of origin |

|

|

1 |

Main motor |

CPG |

Taiwan |

|

2 |

Frequency converter |

JETTECH |

USA |

|

3 |

HMI |

PANELMASPER |

Taiwan |

|

4 |

Step belt |

continental |

Germany |

|

5 |

Main bearing |

NSK/SKF |

Japan / Switzerland |

|

6 |

Main shaft |

Taiwan |

|

|

7 |

Feeding belt |

NITTA |

Japan |

|

8 |

Converting belt |

NITTA |

Japan |

|

9 |

PLC |

FATEK |

Taiwan |

|

10 |

Electrical components |

Schneider |

France |

|

11 |

Straight track |

Hiwin |

Taiwan |

|

12 |

nozzle |

Taiwan |

|

|

13 |

Electronic Sensor |

Sunx |

Japan |

|

|

|||

|

Accessories and specification |

Quantity |

unit |

|

|

1 |

Operating toolbox and tools |

1 |

set |

|

2 |

optical counter |

1 |

set |

|

3 |

Box-kick counter |

1 |

set |

|

4 |

Spray counter |

1 |

set |

|

5 |

Horizontal pad |

30 |

pcs |

|

6 |

15m horizontal tube |

1 |

strip |

|

7 |

Crash-lock bottom function set |

6 |

set |

|

8 |

Crash-lock bottom function mold |

4 |

set |

|

9 |

Computer monitor |

1 |

set |