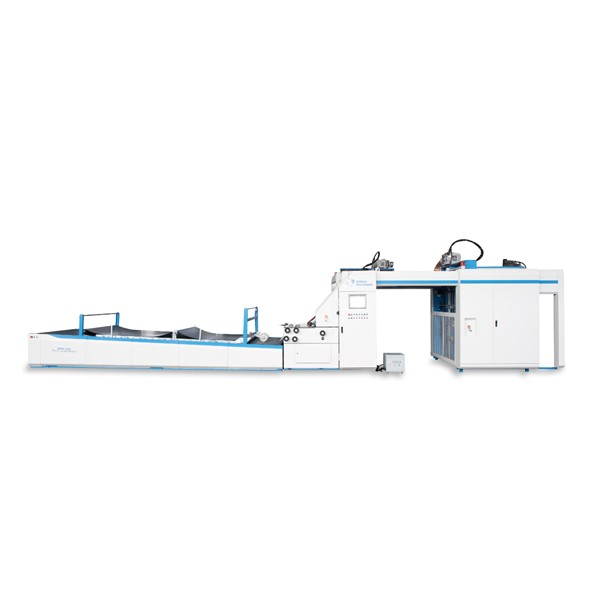

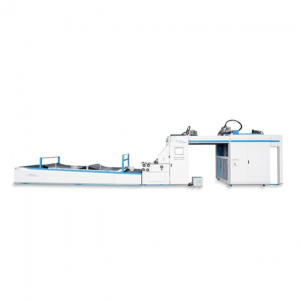

EUFM Automatic high speed flute laminating machine

The paper can be laminated with paperboard to increase the strength and thickness of the material or special effects. After the die-cutting, it can be used for packaging boxes, billboards and other purposes.

| Model | EUFM1450 | EUFM1650 | EUFM1900 |

| Max size | 1450*1450mm | 1650*1650mm | 1900*1900mm |

| Min size | 380*400mm | 400*450mm | 450*450mm |

| Paper | 120-800g | 120-800g | 120-800g |

| Bottom paper | ≤10mm ABCDEF corrugated board ≥300gsm cardboard | ≤10mm ABCDEF corrugated board ≥300gsm cardboard | ≤10mm ABCDEF

corrugated board ≥300gsm cardboard |

| Max laminating speed | 150m/min | 150m/min | 150m/min |

| Power | 25kw | 27kw | 30KW |

| Stick accuracy | ±1.5mm | ±1.5mm | ±1.5mm |

1.BOTTOM SHEET FEEDING

Use imported Servo motor electric controlling system, with Japan NITTA suction belt to make suction power inverter, and belt cleaned by water roller; Patented technology to ensure corrugate and cardboard goes out smoothly and simple operation.

2.TOP SHEET FEEDING MECHANISM

Both paper lifting and feeding nozzle of high speed auto dedicated feeder can be freely adjusted to be adapted to both thin and thick paper. Together with Becker pump, ensure top feeding paper run fast and smoothly.

3.ELECTRICAL SYSTEM

Designed and adopt U.S.A Parker motion controller together with Yaskawa Servo system and inverter, Siemens PLC to ensure machine run at max. speed and accuracy as premium performance and running stability.

4.PRE-STACK PART

Pre-pile system with preset function can be set as paper size through touch screen and oriented automatically to reduce set-up time efficiently.

5.Transmission System

Gates synchronical belt together with SKF bearing as main transmission is adopted to ensure stability. Both pressure rollers, dampening roller and glue value can be easily adjusted by handle with mechanical encoder.

6.POSITIONING SYSTEM

Photocell together with Parker Dynamic module and Yaskawa Servo system ensure the accuracy of orientation of top and bottom paper. Stainless steel glue roller with fine anilox grinding to guarantee even glue coating even at min. glue quantity

7.TOUCH SCREEN AND AUTOMATIC ORIENTATION

Paper format can be set through 15inch Touch Monitor and oriented through inverter motor automatically to minimize set-up time. The Auto orientation is applied to pre-pile unit, top feeding unit, bottom feeding unit and positioning unit. Eaton M22 series button ensure long duty time and machine beauty.

8.CONVEYOR

Lifted convey unit facilitate operator to unload paper. Long convey unit together with pressure belt to make laminated job dry rapidly.

9.AUTOMATIC LUBRICATION SYSTEM

Automatic lubrication pump for all main bearing ensure machine strong endurance even under heavy duty working condition.

OPTIONS:

1.LEADING EDGE FEEDING SYSTEM

Lead edge ensure thick corrugated board like 5 or 7 layers run smoothly even under very curing condition.

2.SHAFTLESS SERVO FEEDER

Shaftless servo feeder is utilized for extra long sheet at flexible motion.

3.EXTRA SAFETY GUARD AND SAFETY RELAY

Extra closed cover around the machine for additional safety assistance. Safety relay to ensure door switch and E-stop function redundantly.