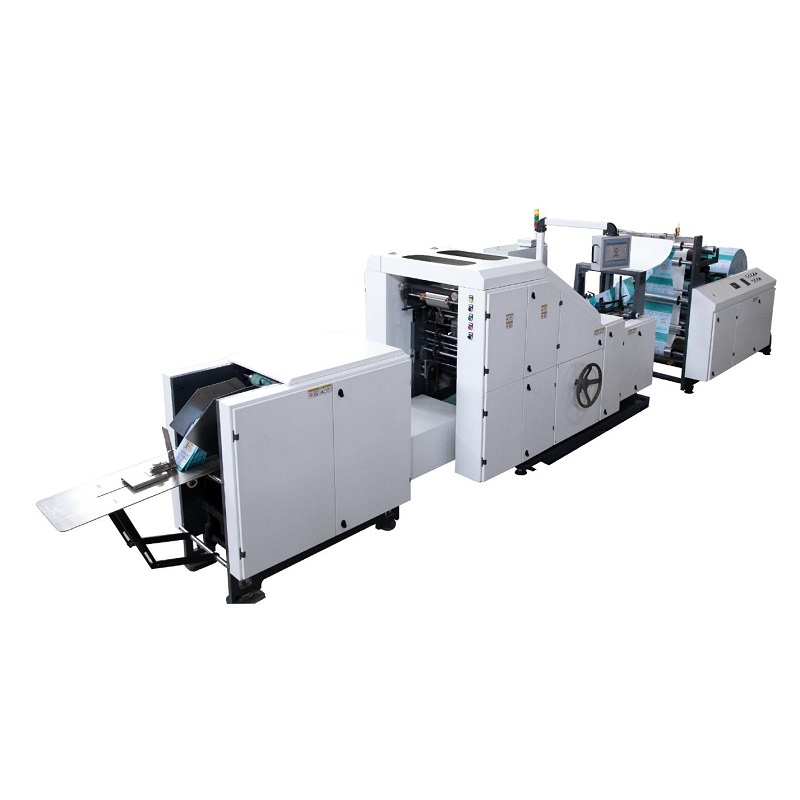

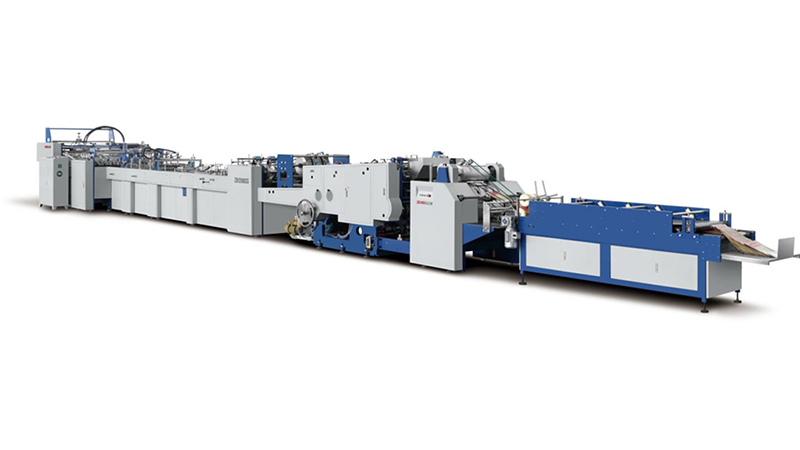

factory Outlets for Printech Paper Bag Machine - ZB1200CS-430 Automatic Sheet Feeding Paper Bag Making Machine – Eureka

factory Outlets for Printech Paper Bag Machine - ZB1200CS-430 Automatic Sheet Feeding Paper Bag Making Machine – Eureka Detail:

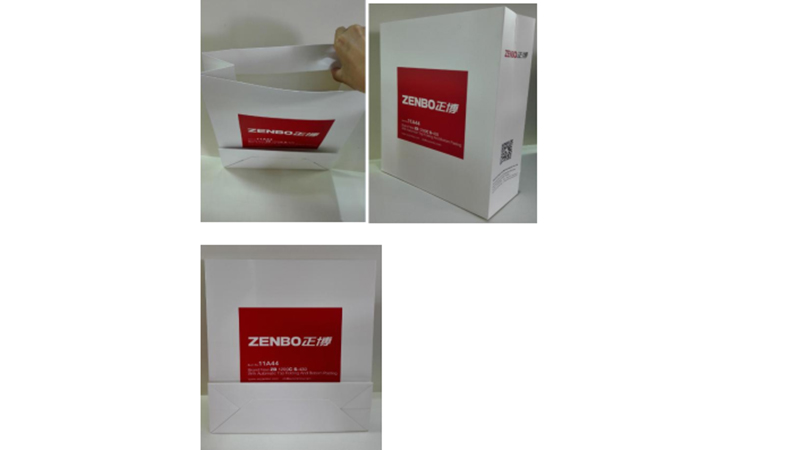

Art paper, white board and ivory board need lamination. Over 170gsm need die-cutting in advance. 140/150gsm craft paper and 150/157gsm art paper no need die-cutting.

| Input Max.Sheet Size |

1200x600mm |

| Input Min. Sheet Size |

540x320mm |

| Sheet Weight |

140-300gsm |

| Bag Width |

180-430mm |

| Bottom Width |

80-175mm |

| Bag Length |

220-500mm |

| Top Folding Depth |

30-70mm |

| Speed |

50-80pcs/min |

| Working Power |

11KW |

| Machine Weight |

12T |

| Machine Size |

17500x2400x1800mm |

| Glue Type |

Water soluble cold glue(hot-melt glue) |

Main Part and Origin

| No. | Item | Origin | Brand | No. | Item | Origin | Brand |

| 1 | Feeder | China | RUN | 8 | Main Bearings | Germany | BEM |

| 2 | Motor | China | Fangda | 9 | Convey Belt | Japan | NITTA |

| 3 | PLC | Japan | Mitsubishi | 10 | Touch Screen | Taiwan China | WEINVIEW |

| 4 | Frequency Converter | France | Schneider | 11 | Vaccum Pump | Germany | BECKER |

| 5 | Button | Germany | Eaton Moller | 12 | Pneumatic Elements | Taiwan China | AIRTAC |

| 6 | Electric Relay | Germany | Weidmuller | 13 | Photoelectric Sensor | Korea/Germany | Autonics/SICK |

| 7 | Air Switch | Germany | Eaton Moller | 14 | Hote melt glue system | Amercia | Nordson |

Our company reserves the right to change technical characteristics without further notice.

1. Automatic feeder unit

2. Automatic top folding unit

3. Automatic side pasting unit

4. Automatic gusset forming unit

5. Automatic bottom folding unit

6. Automatic bottom gluing unit

7. Automatic bottom pasting unit

8. Screw rod adjusting bottom clip system(can save adjustment time)unit

Product detail pictures:

Related Product Guide:

We constantly carry out our spirit of ''Innovation bringing advancement, Highly-quality guaranteeing subsistence, Administration selling advantage, Credit rating attracting buyers for factory Outlets for Printech Paper Bag Machine - ZB1200CS-430 Automatic Sheet Feeding Paper Bag Making Machine – Eureka , The product will supply to all over the world, such as: Panama, Kyrgyzstan, Jamaica, After years' creating and developing, with the advantages of trained qualified talents and rich marketing experience, outstanding achievements were gradually made. We get good reputation from the customers due to our good solutions quality and fine after-sale service. We sincerely wish to create a more prosperous and flourishing future together with all the friends home and abroad!

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!

Write your message here and send it to us