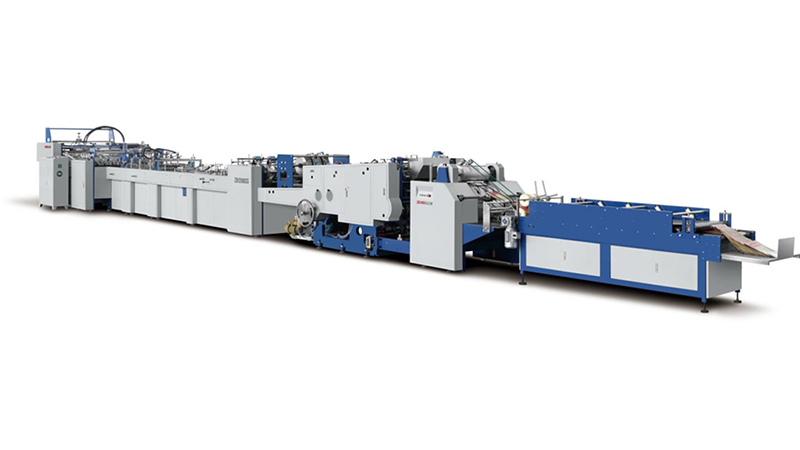

Factory source Paper Bag Folding Machine - ZB1200CS-430 Automatic Sheet Feeding Paper Bag Making Machine – Eureka

Factory source Paper Bag Folding Machine - ZB1200CS-430 Automatic Sheet Feeding Paper Bag Making Machine – Eureka Detail:

Art paper, white board and ivory board need lamination. Over 170gsm need die-cutting in advance. 140/150gsm craft paper and 150/157gsm art paper no need die-cutting.

| Input Max.Sheet Size |

1200x600mm |

| Input Min. Sheet Size |

540x320mm |

| Sheet Weight |

140-300gsm |

| Bag Width |

180-430mm |

| Bottom Width |

80-175mm |

| Bag Length |

220-500mm |

| Top Folding Depth |

30-70mm |

| Speed |

50-80pcs/min |

| Working Power |

11KW |

| Machine Weight |

12T |

| Machine Size |

17500x2400x1800mm |

| Glue Type |

Water soluble cold glue(hot-melt glue) |

Main Part and Origin

| No. | Item | Origin | Brand | No. | Item | Origin | Brand |

| 1 | Feeder | China | RUN | 8 | Main Bearings | Germany | BEM |

| 2 | Motor | China | Fangda | 9 | Convey Belt | Japan | NITTA |

| 3 | PLC | Japan | Mitsubishi | 10 | Touch Screen | Taiwan China | WEINVIEW |

| 4 | Frequency Converter | France | Schneider | 11 | Vaccum Pump | Germany | BECKER |

| 5 | Button | Germany | Eaton Moller | 12 | Pneumatic Elements | Taiwan China | AIRTAC |

| 6 | Electric Relay | Germany | Weidmuller | 13 | Photoelectric Sensor | Korea/Germany | Autonics/SICK |

| 7 | Air Switch | Germany | Eaton Moller | 14 | Hote melt glue system | Amercia | Nordson |

Our company reserves the right to change technical characteristics without further notice.

1. Automatic feeder unit

2. Automatic top folding unit

3. Automatic side pasting unit

4. Automatic gusset forming unit

5. Automatic bottom folding unit

6. Automatic bottom gluing unit

7. Automatic bottom pasting unit

8. Screw rod adjusting bottom clip system(can save adjustment time)unit

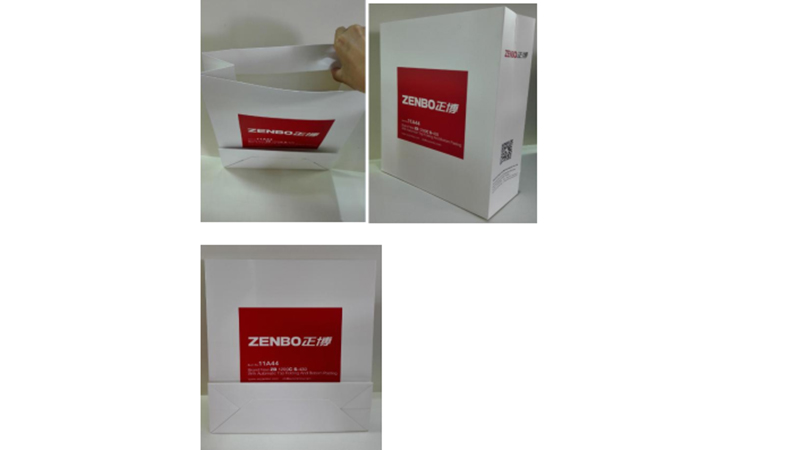

Product detail pictures:

Related Product Guide:

we are able to provide good quality items, aggressive rate and best shopper assistance. Our destination is "You come here with difficulty and we provide you with a smile to take away" for Factory source Paper Bag Folding Machine - ZB1200CS-430 Automatic Sheet Feeding Paper Bag Making Machine – Eureka , The product will supply to all over the world, such as: Lisbon, French, Luxembourg, We've got constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. In depth Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Portugal for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.

Write your message here and send it to us