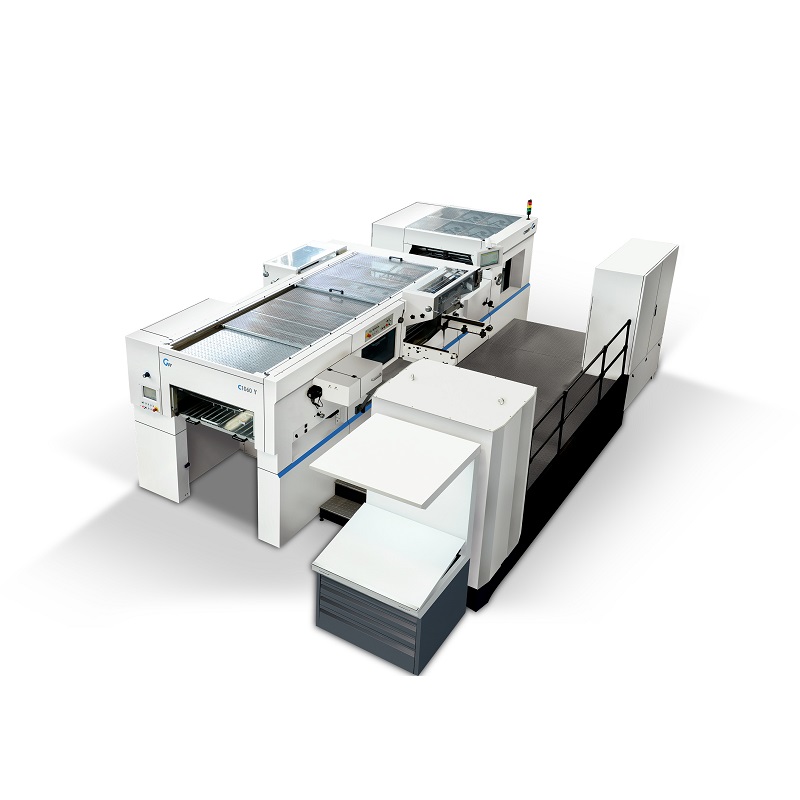

Factory Supply Used Flat Bed Die Cutting Machine - GUOWANG T-1060Q DIE-CUTTER WITH STRIPPING – Eureka

Factory Supply Used Flat Bed Die Cutting Machine - GUOWANG T-1060Q DIE-CUTTER WITH STRIPPING – Eureka Detail:

This machine combines the new technical advantages of T1060B, is the first model with stripping function in domestic market. Adopting double cam gripper technology.

Clearance box can optional use Japan Sankyo. Can make the machine more stable and reliable when the operation meets emergency stops. Stripping chase adopt automatic pneumatic lifting function, quick lock system and center line alignment positioning system. It can make operation easier and more convenient. Operation screen adopts 19 inches HD LED Touch screen, makes the most complex settings simple and intuitive, greatly improve the efficiency of equipment. Auxiliary delivery table is with automatic delivery function.

| Maximum paper size | 1060*760 | mm |

| Minimum paper size | 400*350 | mm |

| Maximum cutting size | 1060*745 | mm |

| Maximum Die-cutting plate size | 1075*765 | mm |

| Die-cutting plate thickness | 4+1 | mm |

| Cutting rule height | 23.8 | mm |

| First die-cutting rule | 13 | mm |

| Gripper margin | 7-17 | mm |

| Cardboard spec | 90-2000 | gsm |

| Cardboard thickness | 0.1-3 | mm |

| Cirrugated spec | ≤4 | mm |

| Maximum working pressure | 350 | t |

| Maximum die-cutting speed | 8000 | S/H |

| Feeding board height (incl. pallet) | 1800 | mm |

| Non-stop feeding height(incl. pallet) | 1300 | mm |

| Delivery height(incl. pallet) | 1400 | mm |

| Main motor power | 11 | kw |

| Whole machine power | 17 | kw |

| Voltage | 380±5% 50Hz | v |

| Cable thickness | 10 | mm² |

| Air pressure requirement | 6-8 | bar |

| Air consumption | 200 | L/Min |

FEEDER UNIT

High quality feeder, 4 pick-up suckers and 4 forward suckers, ensure stable and fast feeding.

Pre-loading device to feed paper without stopping the machine, maximum stack height 1800mm

Pre-loading tracks help the operator push paper stack to feeding position accurately and conveniently.

Side lays can be adjusted to fit different paper.

Paper transferred to the front lay will slow down to ensure accurate positioning.

Transferring plate is stainless steel imported from Germany to make the paper conveying smooth and fast.

DIE-CUTTING UNIT

Japanese Fuji servo motor, to achieve the precision and stable control of die cutting pressure,

Makes accurate adjustment through the 19 inch touch screen with precision to 0.01mm.

Die cutting chase and plate are locked by Japanese SMC pneumatic cylinder, to avoid the upper and lower chases out of position and operating losses caused by human factors.

Die cutting chase adopts the center-line device for fast positioning , so that the operator don’t need to consider the left-right position of the die board.

Die cutting boards of non-standard size can also be installed by using auxiliary tools to facilitate applicability of customers’ cutting boards from different models .

Gripper bar, of special aluminum alloy , the surface after oxidation treatment, adopts double-cam opening method to release the paper during running. It can reduce the inertia of paper to collect the thin paper in order easily.

Intermittent box from Japan SanDex to assure precise positioning even in high speed die-cutting.

DELIVERY UNIT

Motorized curtain style Non-stop delivery unit.

Max. pile height is up to 1600mm to reduce the loading time for operator and raise efficiency.

Max. pile height is up to 1600mm to reduce the loading time for operator and raise efficiency.

10.4” high resolution touch screen. The operator can observe all the setting in different position redue the time for job changing and improve working efficiency.

STRIPPING UNIT

Adopts pneumatic lifting function.

Adopts center-line positioning and quick-lock device for stripping board .

Stripping chase position memorization.

| Configurations | Country of origin |

| Feeding unit | |

| Jet-feeding Mode | |

| Feeder head | China/German MABEG(option) |

| Pre-loading device, Non-stop feeding | |

| Front & side lay photocell induction | |

| Light guard protecting device | |

| Vacuum pump | German Becker |

| Pull/push switch type side guide | |

| Die-cutting unit | |

| Die chase | Japan SMC |

| Centre line alignment system | |

| Gripper mode adopt latest double cam tech | Japan |

| Pre-stretched high quality chain | German |

| Torque limiter and index gear box drive | Japan Sankyo |

| Cutting plate pneumatic ejecting system | |

| Automatic lubrication and cooling | |

| Automatic chain lubrication system | |

| Main motor | German SIEMENS |

| Paper miss detector | German LEUZE |

| Stripping unit | |

| 3-way stripping structure | |

| Centre line alignment system | |

| Pneumatic lock device | |

| Quick lock system | |

| Bottom feeder | |

| Delivery unit | |

| Non-stop delivery | |

| Delivery motor | German NORD |

| Secondary delivery motor | German NORD |

| Electronic parts | |

| High quality electrical components | EATON/OMRON/SCHNEIDER |

| Safety controller | German PILZ safety module |

| Main monitor | 19 inch AMT |

| Secondary monitor | 19 inch AMT |

| Inverter | SCHNEIDER/OMRON |

| Sensor | LEUZE/OMRON/SCHNEIDER |

| Switch | German MOELLER |

| Low-voltage distribution | German MOELLER |

Product detail pictures:

Related Product Guide:

We strive for excellence, services the customers", hopes to be the top cooperation team and dominator business for personnel, suppliers and prospects, realizes benefit share and continual promotion for Factory Supply Used Flat Bed Die Cutting Machine - GUOWANG T-1060Q DIE-CUTTER WITH STRIPPING – Eureka , The product will supply to all over the world, such as: Chile, Honduras, Belgium, We have constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Portugal for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.