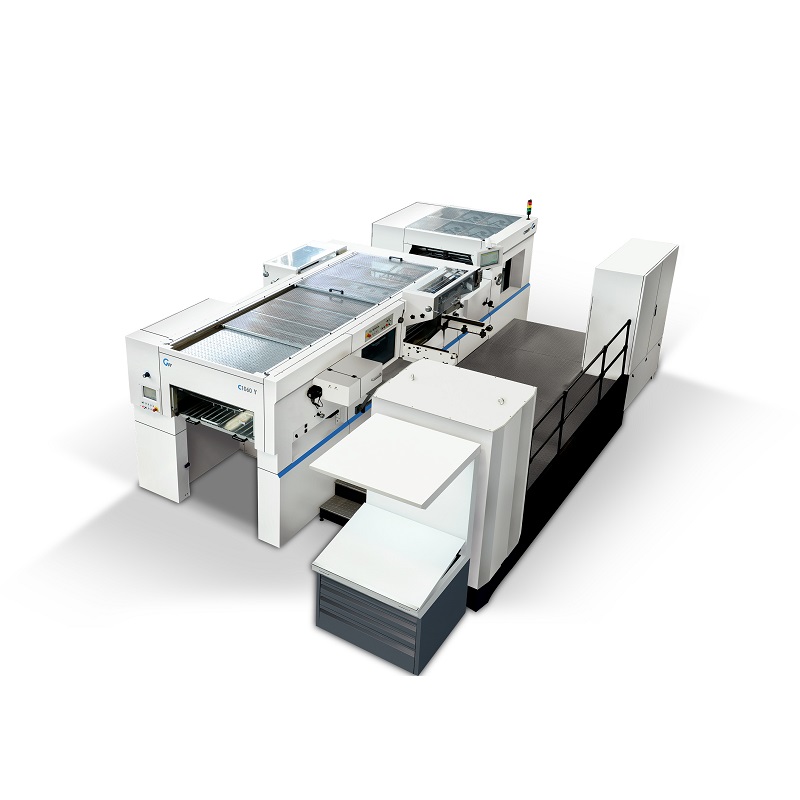

Factory wholesale Paper Sheeter - GW PRECISION SHEET CUTTER S140/S170 – Eureka

Factory wholesale Paper Sheeter - GW PRECISION SHEET CUTTER S140/S170 – Eureka Detail:

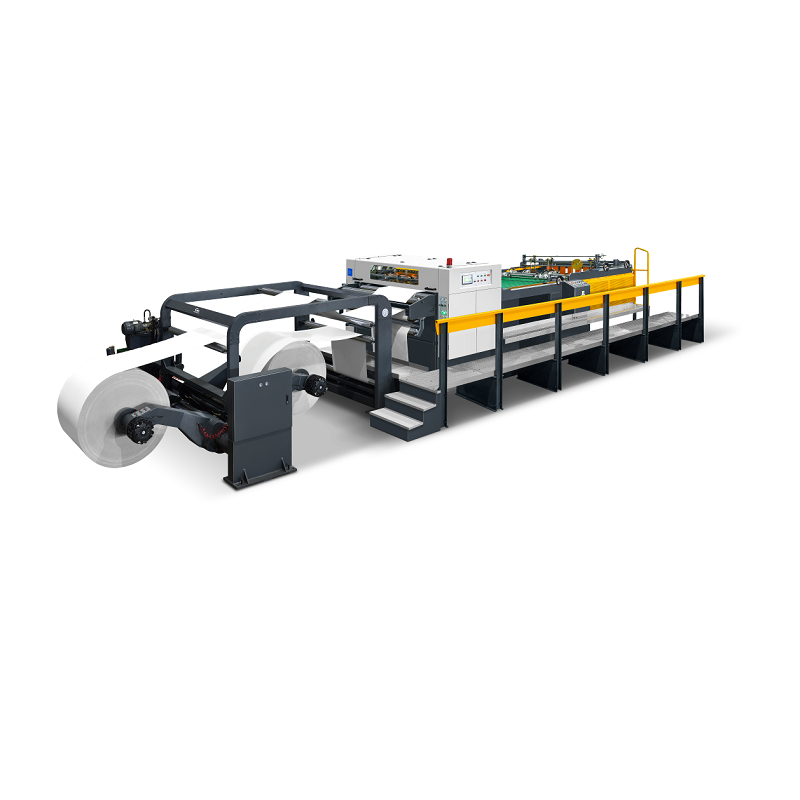

According to GW product’s technics, The machine are mainly used for paper sheeting in Paper Mill, Printing House and etc, mainly process including: Unwinding—Cutting—Conveying—Collecting,.

1.19″ touch screen controls are used to set and display sheet size, count, cut speed, delivery overlap, and more. The touch screen controls work in conjunction with a Siemens PLC.

2. Three sets of shearing type slitting unit to have a high speed, smooth and powerless trimming and slitting, with quick adjustment and locking. High rigidity knife holder is suitable for 300m/min high speed slitting .

3.The fast/slow speed belt is controlled by the stepless frequency converter, which automatically tracks the knife speed and adjusts the belt speed, so that the paper can be perfectly overlapped.

4. Upper knife roller has the British cutter method to effectively reduce the load and noise during paper cutting, and to extend the life of the cutter. The upper knife roller is welded with stainless steel for precision machining, and is dynamically balanced during high-speed operation.

Lower tool seat is made of cast iron integrally formed and cast, and then precision processed, with good stability.

Active roller surface is designed with expansion lines, and the cylinder is used to control the pressure and paper clamping of the roller body.

Rotary cutting knife is made of special alloy steel precision machining, with long service life and easy adjustment of the blade.Safety cover will automatically shut down when the safety cover is opened, ensuring safety.

| Model | GW-S140/S170 |

| 1. Type of cutting | Top blade rotary, bottom blade fixed |

| 2. weight of paper | 60-550 GSM |

| 3..reel diameter | Max 1800mm |

| 4. Finished width | Max 1400mm/1700mm |

| 5. Finished sheet-Length | Min.450-Max.1650 mm |

| 6. Num.of rolls cutting | 2 rolls |

| 7. Cutting accuracy | ±0.3mm |

| 8. Max.speed of cutting | 350cuts/min |

| 9. Max.cutting speed | 300m/min |

| 10.Delivery pile height | 1500mm |

| 11. Requirement of the air pressure | 0.8MPa |

| 12. Voltage | AC380V/220Vx50Hz |

| 13. Main motor power: | 11KW |

| 13. Output | The real output depend on the material, and the weight of the paper, and right operate process |

| 1. | Dual position shaftless pivoting arm unwind stand |

| 2. | Middle Slitting And Waste Edge Collecting System |

| 3. | High precision single rotary sheet cutter |

| 4. | Squareness Adjustment System |

| 5. | Static Eliminator System |

| 6. | Paper Conveyer System |

| 7. | Auto counting and Label inserting device |

| 8. | Delivery and Auto Jogger System |

| 9. | Driving Motor system |

| 10. | Driving Motor system |

| 11. | Motorized double decurler |

| 12. | Auto-tension control |

| 13. | Auto-EPC (Edge Paper Control) |

1. Dual position shaftless pivoting arm unwind stand

1)Max Reel Diameter: 1800mm

2)Max Reel width: 1400mm/1700mm

3)Min Reel width: 500mm

4)Core size : 3″6″12″

5)Hydraulic driving : 3.5kw

6)Clip arm move forward or back driven by hydraulic

7)Clip arm up or down driven by hydraulic

8)Pneumatic brake system

9)Dancing roll with related bracket

2. Middle Slitting And Waste Edge Collecting System

1)Style Adjustable slitting knife and exhaust tube for waste edge on both sides

2)Top slitter Adjustable up or down, slitting width can be adjusted manually

3)Bottom slitter The slitter are fixed, slitting width can be adjusted by manual

4)Trimming waste vacuum blower: driven by 1.5kw motor

5)Type-Y collecting pipe for waste edge

3. High precision single rotary sheet cutter

1)Top Rotary Knife Adopting cutting way of British, so as to decrease noise and load and prolong life of knife,

2)Bottom Tool Tool Apron cast on time, then processing, with characteristic of stability.

3)Main driving roller: grainy surface, controlled by the air Pressure so as to grip the paper

4. Squareness Adjustment System

1)Type:Tool Apron fixed as the way of British, more efficiency。

2)Control Way:Squareness of paper according to calibration through the staff gauge.

5. Static Eliminator System

1)Type: Anti-static bar, can eliminate static in the sheets.

6. Paper Conveyer System

1)Type: Horizontal conveying with multi-stage so as to counting and piling conveniently (high efficiency dust collecting equipments)

2)The first conveying stage To separate cutting paper quickly

3)The Second conveying stage To conveyer paper like shape of tile with slow speed, single or linkage acting control

4)Delivery conveying stage Refined separating device can strengthen stability and avoid deviation of paper.

7. Siemens PLC, INVT Servo Driver and motor, Schneider inverter, imported electrical components

8. Auto counting and Label inserting device

1)Type: Insert after counting precisely

2)Function:

A、After inputting number of paper pieces in HMI,

then it can work according to requirements.

B、Refill defective product

9. Delivery and Auto Jogger System

1)Type: Automatically goes down when paper piling up to a certain height.

2)Height of paper stack

3)Size of finished paper

4)Weight of Stacker

5)Jogger: Max.1500mm, W=1400mm, L=1450mm, 2500kg, Dynamic type jogger for front and both sides; adiustable type tailgate.

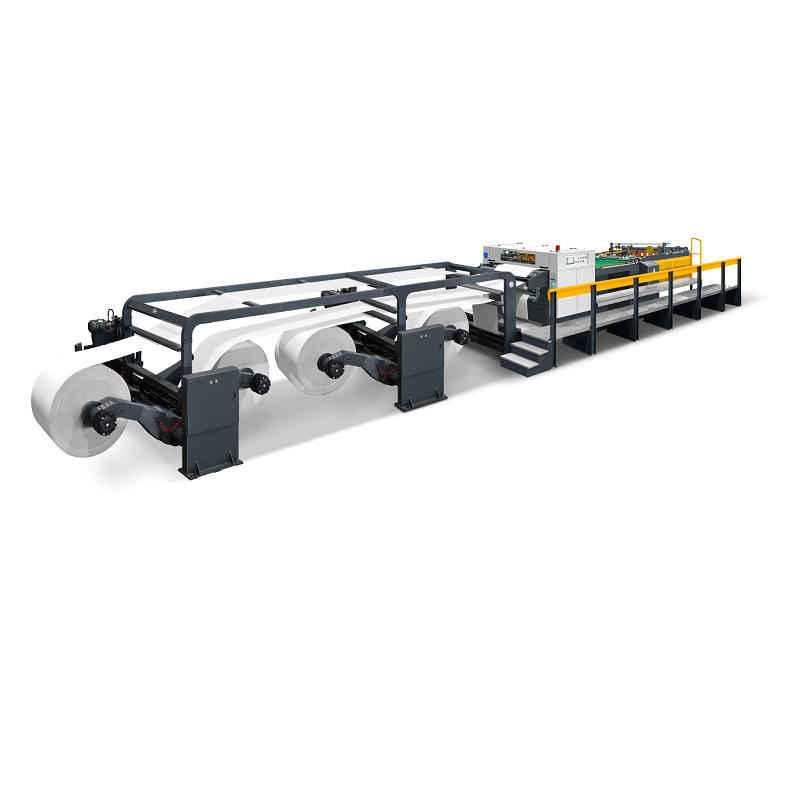

10. Motorized double decurler

This newly designed decurler can flatten the thick paper

with a much better result than the conventional decurler

system, which enable this machine practically to run thick

board till 1000gsm

11. Auto-EPC (Edge Paper Control)

Precision sensing nozzle which easily available and sensitive

Fast detects various web lines for EPC system.

12. Auto-tension control

Put the paper roll diameter and paper weight number into touching screen, the tension will be controlled by computer Automatically. Picture for 4 rolls web guiding system.

13. Driving Motor system

1)AC servo motor for reclaiming blade 2)AC motor for conveyer paper 3)Inverter motor for the secondly conveyer strap 4)AC motor for up and down of Stacker 5)AC motor for front jogger 6)AC motor for windmill of collecting waste edge 7)AC motor for unwind stand

| 1. | HCT Blade |

| 2. | Pneumatic slitter |

| 3. | 2000mm cutting length |

| 4. | 1650mm Pile height |

| 5. | Dust removal |

| 6. | Cursor tracking |

| 7. | Redundant safety control and interlock safety system |

1. HCT Blade

2. Pneumatic slitter

3. 2000mm cutting length

4. 1650mm Pile height

5. Dust removal

6. Cursor tracking

7. Redundant safety control and interlock safety system

|

PART NAME |

BRAND |

COUNTRY OF ORIGIN |

|

Bearing |

NSK/HRB |

Japan/China |

|

Servo driver |

INVT |

China |

|

Relay |

IDEC |

Japan |

|

PLC |

Siemens |

Germany |

|

Frequency Converter |

INVT |

China |

|

Frequency Converter |

INVT |

China |

|

Servo motor |

INVT |

China |

|

Thermaorelay |

TAIAN |

Taiwan |

|

Switch power supply |

MW |

Taiwan |

|

Monitor |

Siemens |

Germany |

|

AC contacor |

TAIAN |

Taiwan |

|

Inverter motor |

Siemens |

Germany |

|

Pneumatic control |

SMC |

Japan |

|

Circuit breaker |

LS |

Korea |

|

Proximity switch |

FOTEK |

Taiwan |

|

Timing belt |

OPIT |

Germany |

|

Conveyor belt |

Sampla |

joint venture |

|

Motor |

WANSHSIN |

Taiwan |

2 reels unwinder

4 reels unwinder

Through the co-operation with top-level partner in the world, Guowang Group (GW) owns Joint venture company with Germany partner and KOMORI global OEM project. Based on the German and Japanese advanced technology and more than 25 years experience, GW continually offer the best and highest efficient post-press solution.

GW adopts the advanced production solution and 5S management standard, from R&D, purchase, machining, assembling and inspection, every process strictly follow the highest standard.

GW invest a lot in the CNC, import DMG, INNSE- BERADI, PAMA, STARRAG, TOSHIBA, OKUMA, MAZAK, MITSUBISHI etc. from all over the world. Only because pursues the high quality. The strong CNC team is the firm guaranty of the quality of your products. In GW, you will feel the “high efficient and high precision”

Product detail pictures:

Related Product Guide:

Our firm sticks on the theory of "Quality will be the life in the enterprise, and status could be the soul of it" for Factory wholesale Paper Sheeter - GW PRECISION SHEET CUTTER S140/S170 – Eureka , The product will supply to all over the world, such as: Durban, Melbourne, Uruguay, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we will continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.