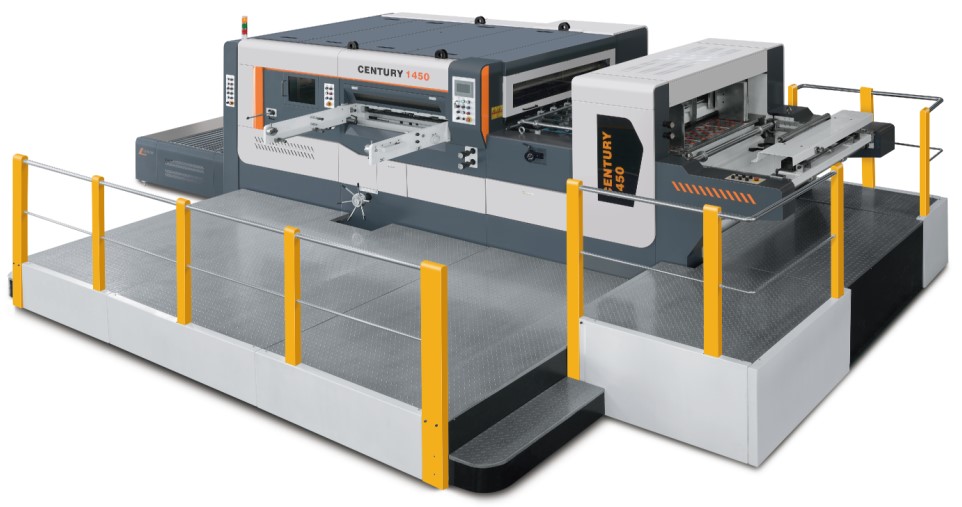

Fast delivery Flat Bed Die - MWZ1620N Lead Edge Automatic Die Cutting Machine with Full Stripping Section – Eureka

Fast delivery Flat Bed Die - MWZ1620N Lead Edge Automatic Die Cutting Machine with Full Stripping Section – Eureka Detail:

| Model | MWZ1620N |

| Max. Paper Size | 1650*1210 mm |

| Min. Paper Size | 650*500 mm |

| Max. Cutting Size | 1620*1190 mm |

| Max. Cutting Pressure | 300×104 N |

| Stock Range | 1mm ≤ Corrugated board ≤ 8.5 mm |

| Die Cutting Accuracy | ±0.5 mm |

| Max. Mechanical Speed | 4000 s/h |

| Pressure adjustment | ±1 mm |

| Minimum Front Margin | 9 mm |

| Inner Chase Size | 1650*1220 mm |

| Total Power | 34.6 KW |

| Machine Dimension | 8368*2855*2677 mm (exclude the work platform, turning frame) |

| Machine Dimension | 10695*2855*2677 mm (include the platform) |

| Total Weight | 27t |

|

No. |

Main Parts |

Brand |

Supplier |

|

1 |

Main driving chain |

Renold |

England |

|

2 |

Bearing |

NSK |

Japan |

|

3 |

Inverter |

Yaskawa |

Japan |

|

4 |

Electrical components |

Omron/Schneider/Siemens |

Japan/Germany |

|

5 |

PLC |

Siemens |

Germany |

|

6 |

Pneumatic Clutch |

OMPI |

Italy |

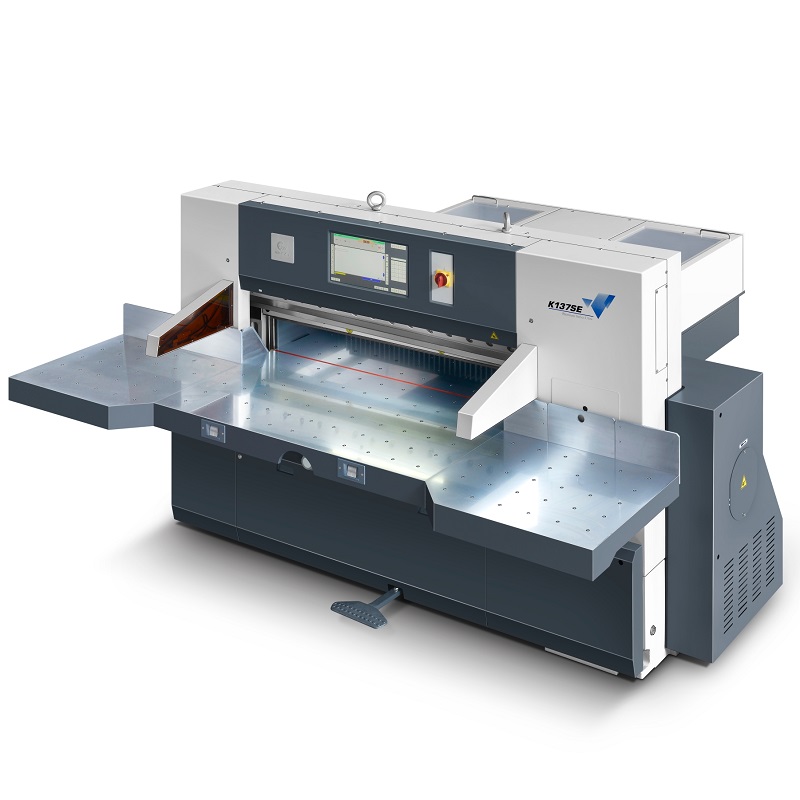

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our firm to the long-term to develop together with consumers for mutual reciprocity and mutual advantage for Fast delivery Flat Bed Die - MWZ1620N Lead Edge Automatic Die Cutting Machine with Full Stripping Section – Eureka , The product will supply to all over the world, such as: Saudi Arabia, New York, Slovenia, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We've got established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance might be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.

Write your message here and send it to us