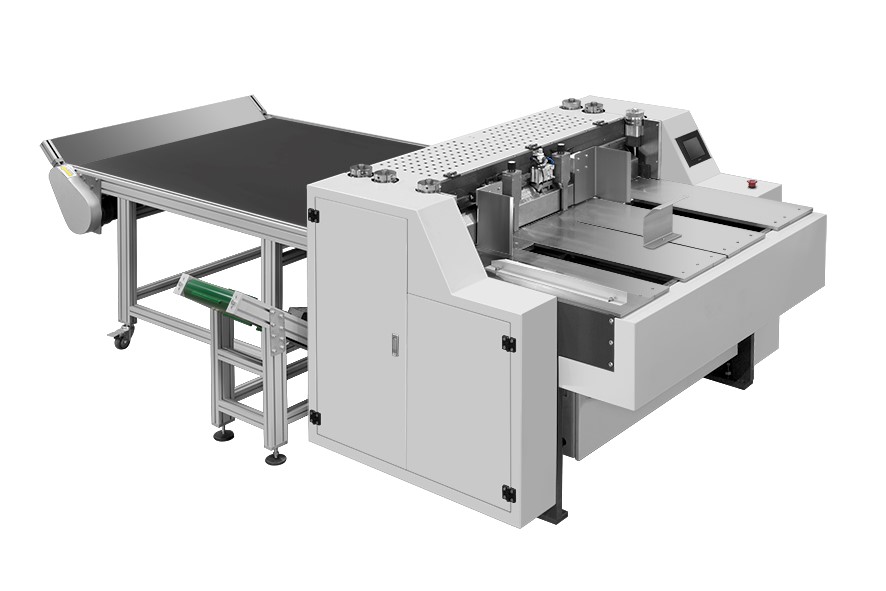

FD-KL1300A Cardboard cutter

1. Feeding large size cardboard by hand and small size cardboard automatically. Servo controlled and setup via touch screen.

2. Pneumatic cylinders control the pressure, easy adjustment of cardboard thickness.

3. The safety cover is designed according to European CE standard.

4. Adopt the concentrated lubrication system, easy to maintain.

5. Main structure is made of casting iron, stable without bending.

6. The crusher cuts the waste into small pieces and discharges them with conveyor belt.

7. Finished production output: with a 2 meter conveyor belt for collecting.

| Model | FD-KL1300A |

| Cardboard width | W≤1300mm, L≤1300mmW1=100-800mm, W2≥55mm |

| Cardboard thickness | 1-3mm |

| Production speed | ≤60m/min |

| Precision | +-0.1mm |

| Motor power | 4kw/380v 3phase |

| Air supply | 0.1L/min 0.6Mpa |

| Machine weight | 1300kg |

| Machine dimension | L3260×W1815×H1225mm |

Remark: We don’t provide air compressor.

|

Name |

Model and function characteristics. |

| Feeder | ZMG104UV,Height: 1150mm |

| Detector | convenient operation |

| Ceramic rollers | Improve printing quality |

| Printing unit | Printing |

| Pneumatic diaphragm pump | safe, energy-saving, efficient and durable |

| UV lamp | improves the wear resistance |

| Infrared lamp | improves the wear resistance |

| UV lamp control system | wind cooling system (standard) |

| Exhaust ventilator | |

| PLC | |

| Inverter | |

| main motor | |

| The counter | |

| The contactor | |

| The button switch | |

| Pump | |

| bearing support | |

| Cylinder diameter | 400mm |

| Tank |

Write your message here and send it to us