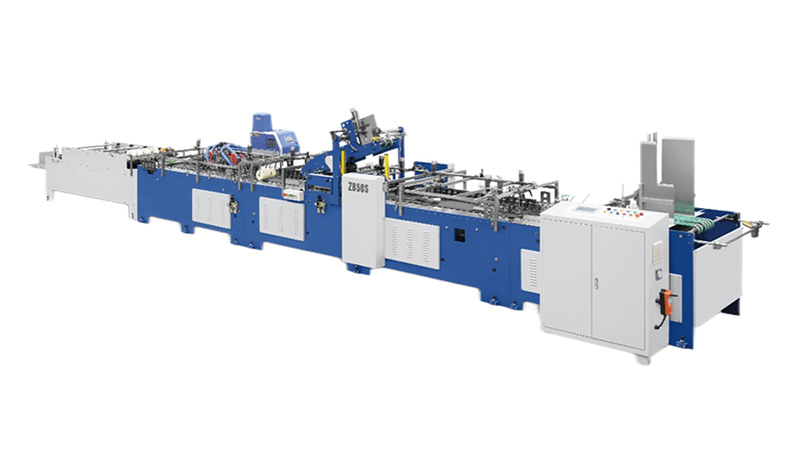

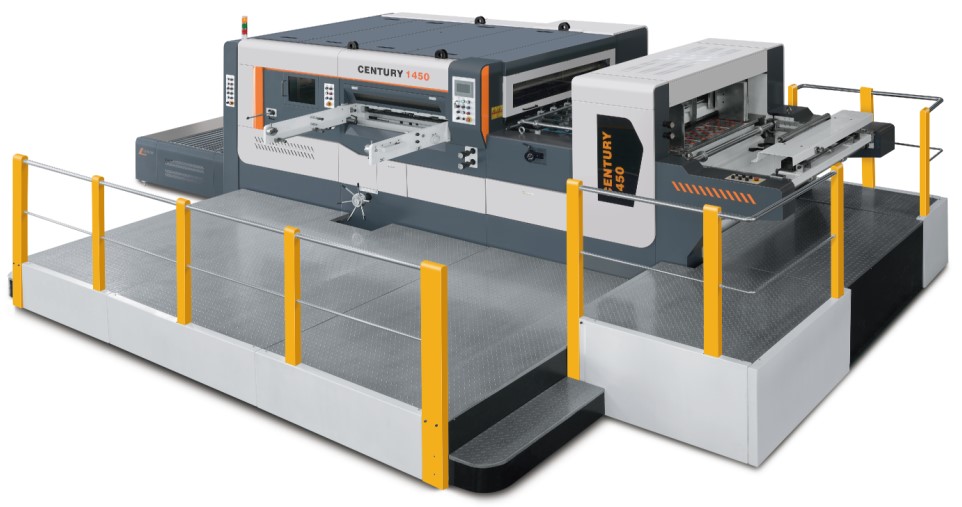

Good quality Flat Bed Die Cutting Machine - MWZ1620N Lead Edge Automatic Die Cutting Machine with Full Stripping Section – Eureka

Good quality Flat Bed Die Cutting Machine - MWZ1620N Lead Edge Automatic Die Cutting Machine with Full Stripping Section – Eureka Detail:

| Model | MWZ1620N |

| Max. Paper Size | 1650*1210 mm |

| Min. Paper Size | 650*500 mm |

| Max. Cutting Size | 1620*1190 mm |

| Max. Cutting Pressure | 300×104 N |

| Stock Range | 1mm ≤ Corrugated board ≤ 8.5 mm |

| Die Cutting Accuracy | ±0.5 mm |

| Max. Mechanical Speed | 4000 s/h |

| Pressure adjustment | ±1 mm |

| Minimum Front Margin | 9 mm |

| Inner Chase Size | 1650*1220 mm |

| Total Power | 34.6 KW |

| Machine Dimension | 8368*2855*2677 mm (exclude the work platform, turning frame) |

| Machine Dimension | 10695*2855*2677 mm (include the platform) |

| Total Weight | 27t |

|

No. |

Main Parts |

Brand |

Supplier |

|

1 |

Main driving chain |

Renold |

England |

|

2 |

Bearing |

NSK |

Japan |

|

3 |

Inverter |

Yaskawa |

Japan |

|

4 |

Electrical components |

Omron/Schneider/Siemens |

Japan/Germany |

|

5 |

PLC |

Siemens |

Germany |

|

6 |

Pneumatic Clutch |

OMPI |

Italy |

Product detail pictures:

Related Product Guide:

With our outstanding administration, powerful technical capability and strict top quality handle procedure, we go on to provide our purchasers with reliable good quality, reasonable selling prices and excellent services. We goal at becoming certainly one of your most responsible partners and earning your gratification for Good quality Flat Bed Die Cutting Machine - MWZ1620N Lead Edge Automatic Die Cutting Machine with Full Stripping Section – Eureka , The product will supply to all over the world, such as: Burundi, Detroit, Singapore, We provide good quality but unbeatable low price and the best service. Welcome to post your samples and color ring to us .We will produce the goods according to your request. If you are interested in any products we offer, please feel free to contact us directly by mail, fax, telephone or internet. We are here to answer your questions from Monday to Saturday and looking forward to cooperating with you.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.

Write your message here and send it to us