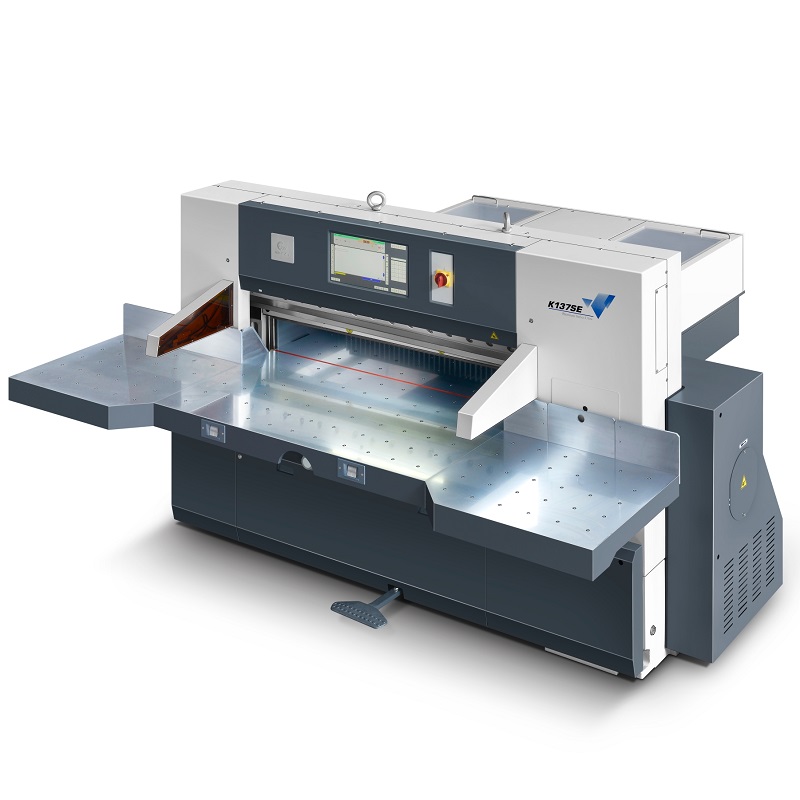

Good Quality Flatbed Diecutting - Automatic Flatbed Die-cutting Machine MWZ-1650G – Eureka

Good Quality Flatbed Diecutting - Automatic Flatbed Die-cutting Machine MWZ-1650G – Eureka Detail:

Built for quick set-up, safety, wide range stock and high productivity.

-The lead edge feeder is able to transfer F flute to double wall corrugated sheets, laminated sheets, Plastic board and heavy industrial board.

-Side push lays and powerless brush wheels for registration.

-Gear driven systems for stable and accurate performance.

-Center line system equipped to be compatible with cutting forms used in flatbed die cutters of other brands. And to offer quick machine setup and job changes.

-Automatic and independent self-lubrication system built to save maintenance job.

-Automatic and independent Self-lubrication system for main drive chain.

-Servo motors of the feeder and frequency inverter and electrical parts of Siemens, which offers higher compatibility with Siemens PLC system and better motion control.

-Double action stripping system with heavy duty movements for positive stripping work.

-Front waste was transferred out of machine via conveyor system.

-Optional device: Automatic waste conveyor system to transfer the waste out under stripping section.

-Auto-batch delivery system.

-Strong and heavy cast-iron built machine body for long life span and stable performance.

-All the parts selected and assembled are built for stable performance and long run.

-Maximum sheet size: 1650 x 1200mm

-Minimum sheet size: 600 x 500mm

-Maximum cutting force: 450Tons

-Applicable to corrugated board converting with thickness from 1-9mm.

-Maximum mechanic speed: 5,500 s/h, which offers a 3000 -5300 s/h production speed depending on sheets quality and operator’s skill.

Lead edge feeder

Height-adjustable back stopper with newly designed for warped sheets.

Surface treated for smooth sheet feeding

High precision and high speed-built lead edge feeder with feeding table make this machine

applicable not only to corrugated board but also to laminated sheets.

With powerful photo-sensors from Panasonic equipped, the machine will stop when the paper

sheet was not fed to the gripper or sheet was not fed flat to the gripper.

Left and right-side joggers will always keep the sheets in alignment. They work together and

also work alone depending on different sheets sizes.

The vacuum suction area support 100% full format: 1650 x 1200mm

Adjustable front gate for sheets with different thickness.

Adjustable support bar to support big format sheets feeding.

Siemens servo motor and Siemens inverter for precise sheets feeding to die cutter

Left and right-side push lays to ensure accurate alignment and power registration.

Micro-adjustment device equipped for micro-adjustment when machine is running in production.

Gripper edge adjust wheel for precise control size of front waste.

Rubber wheel and brush wheel for smooth and accurate sheets feeding to die cutter.

Safety door equipped with magnetic switch for accurate detect and longer service time.

Safety door and die chase safety locking system to ensure safe operation.

Gear driven technology for higher productivity and precision.

Global standard Center line system and self-lock-up system for quick change of cutting die and

short set up. Applicable to the cutting dies from other brand die cutting machines.

Air Floating Device can make easy withdrawing cutting plate

7+2mm hardened cutting steel plate for recycle use.

10’ inch Siemens Human machine interface for easy operation, speed and job monitoring and

malfunctions diagnosis and problems solutions.

Knuckle system with worm gear and worm wheel structure. Maximum cutting force can reach

450T.

Automatic and independent self-lubrication system built to save maintenance job.

Air clutch from Italy brand OMPI

Main bearing from NSK from Japan

Siemens main motor

Automatic and independent Self-lubrication system for main drive chain.

Center line system for quick stripping die set up and job change over and applicable to stripping

dies of other brands die cutting machines.

Safety door equipped with magnetic switch for accurate detect and longer service time.

Motorized upper frame suspending hoister.

Upper stripping frame can be lifted by 400mm, which offers more space for operator to change

stripping tools and solve problems at this section.

Photo sensors for paper waste detecting and keep machine running in neat condition.

Heavy duty double action stripping system to ensure positive stripping.

Male and female type stripping plate for different stripping jobs.

Front waste separator device removes and transfers waste edge to machine drive side by

conveyor belt.

Optional device: Automatic waste conveyor system to transfer the waste out under stripping

section.

Non-stop batch delivery system

Safety door equipped with magnetic switch for accurate detect and longer service time.

Safety window for safety, monitoring delivery action and adjusting the side joggers

Use belt for paper batch transfer to prevent paper scratches.

Press spring chain tensioner and chain safety protection limit switch for longer lifespan of drive

chain and requires less maintenance job for the operator.

Upper knock-off wooden plate to punch off sheets from gripper. Wooden plate to be supplied by

customers themselves.

Siemens touch Panel

Siemens Servo motor

Siemens Electrical part

Siemens inverter

Siemens PLC technology.

All electrical components meet CE standard.

1) Two sets of gripper bars

2) One set of work platform

3) One pc of cutting steel plate (material: 75 Cr1, thickness: 2mm)

4) One set of tools for machine installation and operation

5) One set of consumable parts

6) Two waste collect boxes

7) One set of hydraulic scissors lift for sheets feeding.

| Model NO. | MWZ 1650G |

| Maximum sheet size | 1650 x 1200mm |

| Minimum sheet Size | 650 x 500mm |

| Maximum Cutting Size | 1630 x 1180mm |

| Maximum Cutting Pressure | 4.5 MN (450 Tons) |

| Stock range | E, B, C, A Flute and double wall corrugated board (1-8.5mm) |

| Cutting Precision | ±0.5mm |

| Maximum mechanical Speed | 5,500 cycles per hour |

| Production speed | 3000~5200 cycles/hour (subject to working environment, sheet quality and operation skills, etc.) |

| Pressure Adjusting Range | ±1.5mm |

| Height of Cutting Rule | 23.8mm |

| Minimum Front Waste | 10mm |

| Inner Chase Size | 1660 x 1210mm |

| Machine Dimension (L*W*H) | 11200 x 5500 x 2550mm (including operation platform) |

| Total Power consumption | 41 KW |

| Power supply | 380V, 3PH, 50Hz |

| Net Weight | 36T |

| Part name | Brand |

| Main drive Chain | IWIS |

| Air clutch | OMPI/Italy |

| Main motor | Siemens |

| Electrical Components | Siemens |

| Servo motor | Siemens |

| Frequency Inverter | Siemens |

| Main Bearing | NSK/Japan |

| PLC | Siemens |

| Photo sensor | Panasonic |

| Encoder | Omron |

| Torque Limiter | Customized made |

| Touch screen | Siemens |

| Gripper bar | Aerospace Grade Aluminum |

Automatic pallet supply system

A leading specialist manufacturer and supplier of flatbed die cutters and complete solution for post-press converting lines for corrugated packaging industry for decades.

47000 m2 manufacturing space

3,500 installations completed worldwide

240 employees (February, 2021)

Product detail pictures:

Related Product Guide:

We pursue the administration tenet of "Quality is exceptional, Provider is supreme, Name is first", and will sincerely create and share success with all clientele for Good Quality Flatbed Diecutting - Automatic Flatbed Die-cutting Machine MWZ-1650G – Eureka , The product will supply to all over the world, such as: Bangladesh, Salt Lake City, Cambodia, We are sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy you with our high-quality products and perfect service . We also warmly welcome customers to visit our company and purchase our products.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.