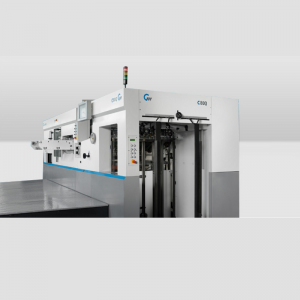

GUOWANG C80Q AUTOMATIC DIE-CUTTER WITH STRIPPING

High quality feeder head

Centre line system

Pneumatic lock die chase

Non-stop feeding and delivery

7500Sheets/H

Max.150T pressure

Dual touch screen for easy operation

HT500-7 ductile casting iron

FEEDER HEAD High quality feeder, 4 sucker and 4 forwarder

FEEDER Pre-pile device, Non-stop feeding Max. Pile height 1600mm

AIR PUMP German BECKER

FEEDING TABLE Nitta convey belt Stainless steel slope convey table

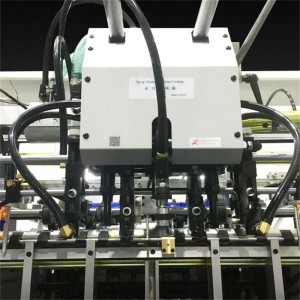

STRIPPING SECTION Center line system Pneumatic upper chase lifting Separate cam to control position for upper, middle, lower chase Higher product quality by automatic stripping

DIE-CUTTING SECTION Servo motor from Japan FUJI Pressure can be adjusted on 15” touch screen, adjusting tolerance up to 0.01mm Max.300T pressure

LED TOUCH SCREEN MONITOR ●15” high definition LED touch screen , the operator can observe all the settings in different position, reduce the time for job changing and improve working efficiency.

LUBRICATION SYSTEM Automatic lubrication system controlled by computer Easy maintanance

DIE-CUTTING SECTION Centre line system Pneumatic lock for upper and lower die chase Switch to detect plates are locked in right position

DELIVERY Max. Pile height 1350mm Non-stop delivery

High quality feeder with 4 suckers for lifting paper and 4 suckers for forwarding paper ensure stable and fast feeding paper. The height and angle of suckers are easily adjustable to keep sheets absolutely straight.

Mechanical double-sheet detector, sheet-retarding device, adjustable air blower ensure sheets transfer to the belt table steadily and precisely.

Vacuum pump is from German Becker.

Lateral pile can be adjusted by motor for accurate sheet feeding.

Pre-piling device makes non-stop feeding with high pile (Max. pile height is up to 1300mm).

Perfect piles can be formed on pallets which run on rails for pre-piling. This makes a significant contribution to smooth production and let operator move the prepared pile to feeder accurately and conveniently.

Single position engagement pneumatic operated mechanical clutch insures the first sheet after every re-start of machine is always fed to front lays for easy, time-saving and material-saving make-ready.

The side lays can be switched directly between pull and push mode on both sides of the machine simply by turning a bolt without having to add or remove parts. This provides the flexibility for processing a wide range of material: irrespective of whether the register marks are to the left or right of the sheet.

l Side and front lays are with precision optical sensors, which can detect dark color and plastic sheet. The sensitivity is adjustable.

Optical sensors with automatic stop system on feeding table enable you to optimize system monitoring- for comprehensive quality control over the entire sheet width and paper jam. Operation panel for feeding part is easier to control the feeding process with LED displayer. PLC and electronic cam for timing control.

Anti-obstacle device can avoid the machine damage.

Swiss Rapplon convey belt for feeder and the speed is adjustable

Pneumatic lock system makes easier lock-up and release of cutting chase and cutting plate.

Centerline system on die-cutting chase with transversal micro adjustment ensures accurate registration that result in quick job changeover.

Accurate positioning of Cutting chase controlled by precision optical sensors with automatic check-lock device

Die chase turnover device.

Siemens main motor controlled by Schneider inverter.

Micro-adjustment of cutting force (pressure accuracy can be up to 0.01mm of encoder, Max. die-cutting pressure can be up to 300 tons) by worm gear driven by servo motor and controlled easily by 15 inch touch screen.

Crankshaft is made of 40Cr steel.

HT300 ductile iron for machine frames and platens.

7 sets of gripper bars with grippers made of lightweight and durable aluminum alloy with ultra hard coat and anodized finish ensure accurate and consistent paper registration.

High quality gripper bar from Japan with long life.

Uniquely designed gripper bar need no spacer for compensation to insure accurate paper registration.

High quality Renold chain from England with pre-extended treatment ensures stability and accuracy in long run.

High pressure index drive system for gripper bar positioning control

Overload protection device with torque limiter creates the highest level of security for operator and machine.

Automatic lubrication and cooling system for main drive and automatic lubrication for main chain.

3-action movement structure with upper, middle and lower stripping frame which are driven respectively by 3 cam wheels which is more tolerant in long run.

Match with the centerline registration system in die-cutting section, the same system also apply to the stripping station to minimize changeover time. Accurate positioning can increase production efficiency.

Stripping pins or male/female die can be used for different stripping jobs.

Configurations

——————————————————————————————————————————————————————————————————————————————–

TAIWAN INDEX BOX U.S.A Synchronical Belt SIEMENS MOTOR

U.K. Renold Chain JAPANESE GRIPPER Becker Pump

——————————————————————————————————————————————————————————————————————————————–

DIEBOARD& STRIPPING BOARD STANDARD

FlOOR LAYOUT

FLOOR PLAN

——————————————————————————————————————————————————————————————————————————————–

Delivery Unit

Adjustable braking brush controlled by AC motor help to unload paper from gripper and piling up paper in higher speed and perfect alignment .

Delivery pile height is up to 1050mm.

Photoelectric devices preventing over-ascending and over-descending of delivery paper pile

Pile can be counted by optical sensor (standard).

The whole machine can be adjusted by 10.4 inch touch monitor in rear side

Auxiliary delivery rack is configured for non-stop delivery.

Electric Parts

Electronic detectors, micro switched and photoelectric cells controlled by PLC on entire machine

Omron Electronic cam switch and encoder

All the major operation can be done by 15 and 10.4 inch touch monitor.

PILZ safety relay as standard ensure highest safety standard.

Internal inter-lock switch fulfill CE requirement.

Applies electric parts including Moeller, Omron, Schneider relay, AC contactor and air breaker to assure stability in long run.

Automatic fault display and self-diagnose.

Installation Data

——————————————————————————————————————————————————————————————————————————————–

Main material

——————————————————————————————————————————————————————————————————————————————–

Paper Cardboard Heavy solid board

Semi-rigid plastics Corrugated board Paper file

——————————————————————————————————————————————————————————————————————————————–

Application Samples