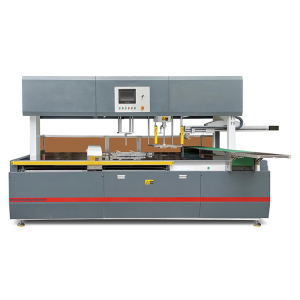

JB-1020 with JB-1050UVJW Stepless UV Dryer and JB-1050S

| Model | JB-1020 | JB-720 | JB-780 |

| Max. Printing area | 1020x700mm | 720x500mm | 780x520mm |

| Size of screen frame | 1280x1140mm | 880x880mm | 940x940mm |

| Paper weight | 120~400g/m2 | 108x400g/m2 | 108~400g/m2 |

| Paper margin | ≤15mm | ≤15mm | ≤15mm |

| Printing speed | 1000~3000pcs/h | 1000~3600pcs/h | 1000~3300pcs/h |

| Power | 3P 380V 50Hz 11.09Kw | 3P 380V 50Hz 6.69Kw | 3P 380V 50Hz 6.69Kw |

| Total weight | 4900kg | 3500Kg | 3800kg |

| Overall dimension | 4.57x2.3x1.52m | 4.1x1.81x1.48m | 4.2x1.87x1.48m |

1. Classical swing cylinder structure with stable and accurate performance. Meanwhile, the photocell is configured on both side layers to detect the orientation status of printing matter to reduce printing waster efficiently.

2. High compatibility with the printing matter of different thickness to ensure well running at high speed. Front single sheet feeder or stream feeder adjustable. Double paper pile is able to be applied to raise efficiency.

3. Together with paper pushing and pressing structure, feeding table has smooth transportation of all kinds of material.

4. Mechanical double sheet and empty sheet detector on the infeeding section.

5. Pneumatic screen and master frame locking

6. Net frame is running along the imported linear guide rail and ball bearing to reduce the noise and vibration at high speed to ensure printing stability.

7. Puller/pusher side layer on the left and right and infinitely adjustable from outside.

8. Outfeeding table move up and down by pneumatic cylinder.

9. The whole machine applies auto-lubrication system to make machine life longer.

10. Imported inverter, PLC and other famous brand electrical components, the whole machine design conform to CE standard.

11. Main parts of machine are built by CNC production equipment to ensure running accuracy.

JB-1050UVJW is specially designed for using with automatic screen printing machine, offset machine and other equipments. It's widely used for dying, dehumidifying and UV curing etc in the field of screen printing, printing and dyeing, electroplating, electronic circuit board and so on.

1. Three groups of stepless regulating light source, independent control, digital instrument real-time indication of the working state and service life.

2. Adopt special aluminum magnesium alloy lampshade, focusing design, high production efficiency.

3.Equipped with a reasonable cooling system, two groups of independent lampshade heat dissipation, the lower part of the adsorption system, to prevent the work chamber temperature is too high, resulting in substrate deformation.

4. The conveyor belt automatic correction system with adsorption system, easy to use, more conducive to the paper conveying; imported Teflon (TEFION) mesh belt, high temperature resistance, friction resistance, stable use to ensure long time.

5. Conveyor frequency stepless speed regulation, visual production adjustment, conveying speed, up to 60 meters/min.

The advantages of stepless variable power light source compared with common transformer controlled UV light source:

Wide energy range output: the output power of the lamp tube is 30% to 100%, stepless adjustable;

High power conversion rate: about 20% higher than traditional transformer drive UV energy, and can effectively extend the lamp life;

High efficiency, energy saving and environmental protection: effectively reduce the loss and reactive power of traditional transformers, save about 40% of the power consumption compared to the same year;

Comprehensive intelligent protection: more than 20 professional protection alarm mechanism, such as overheating of tube, parameter error of lamp tube, disconnection of lamp tube, etc.;

high intelligent power adaptation: standby settings, no material input, 30% power standby; the material is in, within 0.5 seconds automatically to set the power;

The perfect use of safety: avoid the traditional transformer heating and wiring complex caused by security risks.

|

JB-1050UVJW |

|

|

Convey speed |

60m/min |

|

UV lamp power |

9.7 KW×3pcsXstepless type |

|

Wrinkle lamp power |

80W×3pcs×2level |

|

IR heating for ink smooth power |

1.5 KW×3pc |

|

Curing width |

1100 mm |

|

Convey motor power |

400 W |

|

Adsorption fan power |

2.2 KW |

|

Exhaust fan power |

0.37 KW ×3 |

|

Small fan |

40 W×13pcs |

|

Total power |

380V 50Hz 95A |

|

Total Weight |

1200 Kg |

|

Overall size (L*W*H) |

(4.2+0.75) ×1.91×1.78 m |

|

JB-1050S |

|

|

Max. Paper size |

1100×750㎜² |

|

Min. Paper size |

560×350㎜² |

|

Max. Pile height |

700㎜ |

|

Top speed |

3600sheet/h |

|

Installed power |

3P 380V 50Hz 0.92KW |

|

Total weight |

650㎏ |

|

Overall size |

2000×1600×1050㎜³ |

1. The whole machine is controlled by PLC, collecting printing substrate and making the paper in order automatically.

2. Photoelectricity monitoring, two sides of baffles run when the paper come into the plate.

3. Paper conveying system is controlled by inverter with stepless speed regulation and conveyor belt guide the idler wheel to feed the paper.

4. Pneumatical elements control the jogger action, which avoid paper to be broken or other damage.

5. Following all kinds of paper size, paper jogging device can be adjusted from back, left and right easily and conveniently.

6. Induction sensor make the stacking board down automatically and keep paper collect smoothly.

7. Paper stacker has limitation safety mechanism at up and down position to avoid the machine from damaged.

8. Paper jam and paper pile height supervision and make the printing press stop in-line.

9. Connected with the printing part which can control the printing part's running.

10. Paper counting function.