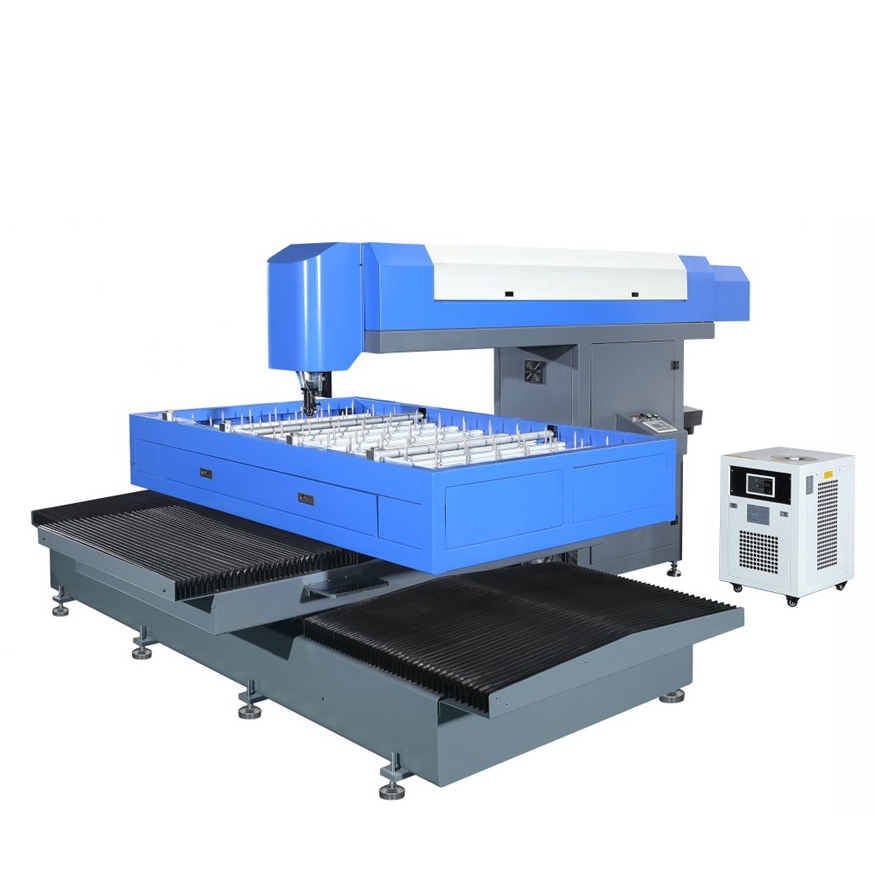

JLDN1812-400W-F Laser Dieboard Cutting Machine

|

1 |

Laser power |

Laser tube power: 400W |

|

|

2 |

Platform |

Across form,laser head fixed.it can prove the laser light’s have maximum stabilization when the machine is working, the across form dirver by X and Y axis move,working area: 1820x1220 mm。the working area by the software and hardware positioning swich curb。 |

|

|

3 |

Transmission |

Use subdivision stepper motor or servo motor ;Double direction import precision ball screw transmission, motor connect with ball screw directly. |

|

|

4 |

Measurement |

Muti-direction following tech. the electronic and light installlation’s calibration precision.seals designs and dust-proof |

|

|

5 |

Abstraction |

By collecting exhaust blower to platform and around place’s smog ,blower can dependence upon place. |

|

|

6 |

Cooler |

The machine is included one set cooler system. Digital program/precision discover’s electron thermostat.exclusive using the air-poof compressor of the laser system | |

|

7 |

Speed |

Cutting speed 50-60cm/min,the cut speed upon to the laser power and, performance and laser light direction , material basis, thickness and shape. |

|

|

8 |

Precision |

Positioning precision:±0.02 mm,repeat precision:±0.02mm,above all of parameter got by 20℃ house digress situation,cut precision belongs to what style material, basis, thickness and shape |

|

|

9 |

Weight |

2.0 tons |

|

|

10 |

Machine Size |

3400mm * 4250mm |

|

|

11 |

Cutting material and thickness |

6-22mm plywood, PVC board and acrylics etc non-metal materials |

|

|

12 |

Input and output file format |

DXF,PLT, AI |

|

|

13 |

Supply power |

Single phase 220V±5% 50HZ-60HZ 15 A (include the machine, water cooler and exhaust fans) |

|

|

14 |

Operating System |

Microsoft windows2000/XP/Vista/WIN7 |

|

|

15 |

Loss part |

Laser tube, reflect mirror,focus lens |

|

|

16 |

Accessorycondition |

Environment |

working interspace: 4300mm×4400mm; about 20 square meter;need install the exhaust fan. |

| Accessory equipment | Equip One 3P air compressor; 5000W regulator、computer(computer and air compressor need to purchase by customer) | ||

Note:This laser cutting machine just can use for die making, if customer want to use for another,must confirm with supplier.