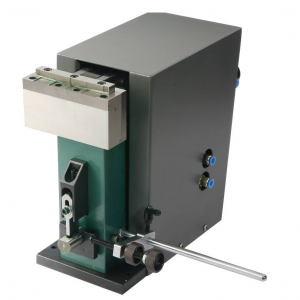

JLSN1812-SM1500-F Laser Dieboard Cutting Machine

1.Fixed laser light road (Laser head is fixed, cutting materials move); laser path is fixed, guarantee the cutting gap is same.

2.Imported high precision grounded ballscrew, precision and used life is higher than rolled ballscrew.

3.High quality linear guideway need not maintenance for 2 years; predigest work time of maintenance

4.High strength and stabilization machine body, cross slipway structure, weight about 1.7T.

5.Electronic floating laser head cutting system, Automatic suitable for bend, different thickness and height materials, guarantee cutting gap all same.

6.Autocephaly dustproof machine control system, airproof grade: IP54, guarantee machine control system working stabilization.

7.German digital control system, included laser cutting power control, machine body operation, laser system operation and expert cutting technology function etc; high speed, high precision and high stabilization, realize perfect laser cutting gap.

8.Laser head adopt drawer style for lens; it is very convenient for replacing and cleaning.

| Laser type | 1500W NT laser generator |

| Working area | 1820*1220MM |

| Laser line path | Fixed laser line path (the laser head fixed, the machine body moved) |

| Drive style | Imported high precision grounded ballscrew |

| Cutting material and thickness | 6-9-15-18-22mm plywood, PVC board, acrylics and less than 4mm steel materials |

| Environment temperature | 5℃-35℃ |

| Cooling water temperature | 5℃-30℃ |

| Cooling water | Pure water |

| Protection gas | non-oil and dry air |

| Relatively humidity | ≤80% |

| Supply power | Three phase 380V±5% 50/60HZ、30KVA |

| Cutting speed | 0-18000mm/min (software setting, 18mm plywood: 1600mm/min) |

| Cutting tolerance | 0.025mm/1250 |

| Repeat tolerance | ≤0.01mm |

| Operation control panel | 15’ LCD, professional control panel of laser cutting system |

| Transmission port | RS232 Net line transmission/USD connection |

| Control software | German PA8000 digital laser control system/Chinese professional digital laser control system |