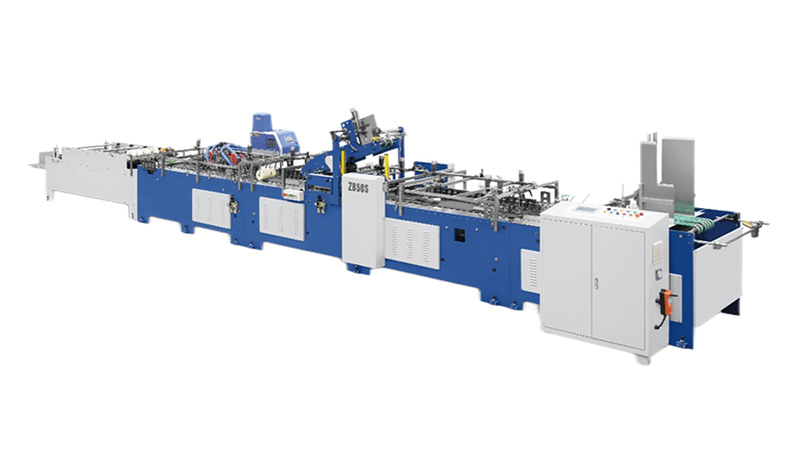

Manufactur standard Sbl Folder Gluer - EF-2800 PCW High Speed Automatic Folder Gluer – Eureka

Manufactur standard Sbl Folder Gluer - EF-2800 PCW High Speed Automatic Folder Gluer – Eureka Detail:

Model EF-2800 machine is multi-functional, mainly for medium package, including 300g -800g cardboard, 1mm-10mm corrugated package. Can produce two folds, crash lock bottom box packaging. The machine also produces on E,C,B,A,AB,EB five facer corrugate board, or Die-cutting and flex-printing slotted corrugated board material, straight line, two folds, crash lock bottom cartons. The whole machine has various set up, it is simple, convenient for operation. The machine is equipped with paper feeding correction locator, continuous box organizing stacker, IHM and PLC system, (option: online diagnose system). With remoter, the transmission structure is with independent motor driver, create smooth and quiet operation. The conveyer’s upper belt is with independent pressure pneumatic control. Equipped with motorized platen, high-power servo motors for crash lock function, high stability, and efficiency, and fulfill convenient operation requirement. This machine is produced according to European CE standards.

● Modulation structure design, can upgrade machine function according to customer’s requirement.

● The whole machine driveway adopts independent synchronized motor drive.

● Special equipped with paper regulator device.

● Strengthen the broadening upper and lower belt drive, suitable for corrugated cartons. The whole machine guide board adjust is electric mobile system, easy commissioning.

● Upper and lower board movement adopts straight line rail system, to ensure the mechanical accuracy of movement .

● Humanized design attachment installation, easy operation.

● A hexagon spanner can adjust the whole set of machine, easy operation.

● Pressing unit has regulator, and collecting unit has patting device, can effectively avoid the “scissors mouth” phenomenon of corrugated products.

● Collecting paper unit adopts cylinder type pressing system, easy for adjust pressure,and make the products can pasted effectively.

● Touch screen control panel.

Remote control convenience for operators to remote control the start and stop of machine.

Technical data:

|

Performance/models |

EF-2800 |

|

Max.sheet size(mm) |

2800*1300 |

|

Min.sheet size(mm) |

520X150 |

|

Applicable paper |

Cardboard 300g-800g |

|

Max.belt speed |

240m/min |

|

Machine length |

22000mm |

|

Machine width |

4200mm |

|

Total power |

45KW |

|

Max.air displacement |

0.7m³/min |

|

Total weight |

16500kg |

The machine is divided into six units, they are feeding, paper regulation, Crash lock folding, pressing and conveyor.

1. Feeding :

Feeding section is driven by12 60mm-width vacuum belts. And 10mm-thickness metal platen to set carton width, embossing wheels to drive the paper belts. The left and right platen can easily move according to the box design. The feeding unit is equipped with three box-feeding knives, can adjust the length according to the box shape and size. The vacuum suction device can cooperate quickly and easily with the motor, feeding continuously and automatically. The feeding stacker can hold cartons up to 400MM height in total. And the upper feeding pressure is pneumatic, ensuring stable and smooth paper feeding, the operator can control the feeding unit by remoter in any position of the machine.

Three-plate structure, using push-side regulation ,can correct paper to ensure feeding stably and smoothly.

Three-plate structure, based on the upper belt is drive type, to ensure stable and smooth paper transport all detachable paste tube; Equipped with lower paste around each cylinder, they have a large capacity. the amount of paste tube can be adjusted, stable, maintenance is simple; provided paste wheel thickness is 10mm-25mm, customers can choose by special requirements; paste tube made of sturdy, durable material; bottom posted by four bottom hook device, cooperated with the completion device. Bottom lower band is 50MM, the upper band is 30MM, the pneumatic pinch plate moves up or down to accommodate different thickness cardboard.

The machine takes three board structure, based on the belt drive type, to ensure stable and smooth paper transport choice and 75 mm wide with an 80mm bottom abduction combination. Left and right sides of the completion of the second fold 180 degrees, 180 degrees fully integrated fourth fold line. Around guide wheel Depending on the position adjusted to fit more smoothly folding box; the bottom bearing support the correct operation of the belt guide. Stealing is independently driven, speed can be adjusted independently abduction. The product does not appear trumpet mark.

Upper and lower drive can adjust the length; equipped with belt straightforward to correct paper at folding progress. Production end affixed to a pneumatic gear box with front flush device box approach ensures continuous automatic product box neatly into the delivery unit. The machine is adopted by electric counter automatic devices with a compressed air system and pressing road transport system. According to different cartridge type, adjust the paper pressure roller, so that the box is pressed against a more perfect.

The machine is with upper and lower independent drive structure. The upper belt may move back and forth the length according to the production of cardboard boxes. The import belt is soft and smooth, will not scratch the final boxes’ surface; The press pressure is well balanced and smoothly transport, to ensure perfect quality. The conveyor unit speed is synchronized with the main machine, will automatic follow up by optical sensor. It can also be adjust by manual. The front part of the conveyor is with two set of press units. Simple and easy to operate and adjust.

|

Outsource list |

|||

|

name |

brand |

Place of origin |

|

|

1 |

main motor |

CPG |

Taiwan |

|

2 |

Frequency converter |

JETTECH |

USA |

|

3 |

HMI |

PANELMASPER |

Taiwan |

|

4 |

Step belt |

continental |

Germany |

|

5 |

Main bearing |

NSK/SKF |

Japan / Switzerland |

|

6 |

Main shaft |

Taiwan |

|

|

7 |

Feeding belt |

NITTA |

Japan |

|

8 |

Converting belt |

NITTA |

Japan |

|

9 |

PLC |

FATEK |

Taiwan |

|

10 |

Electrical components |

Schneider |

France |

|

11 |

Straight track |

Hiwin |

Taiwan |

|

12 |

nozzle |

Taiwan |

|

|

13 |

Electronic Sensor |

Sunx |

Japan |

Standard accessories:

|

Standard accessories: |

|||

|

Accessories and specification |

Quantity |

unit |

|

|

1 |

Operating toolbox and tools |

1 |

set |

|

2 |

optical counter |

1 |

set |

|

3 |

Box-kick counter |

1 |

set |

|

4 |

Spray counter |

1 |

set |

|

5 |

Horizontal pad |

30 |

pcs |

|

6 |

15m horizontal tube |

1 |

strip |

|

7 |

Crash-lock bottom function set |

6 |

set |

|

8 |

Crash-lock bottom function mold |

4 |

set |

|

9 |

Computer monitor |

1 |

set |

Product detail pictures:

Related Product Guide:

We constantly function like a tangible group to ensure that we can give you the very best high-quality and also the very best cost for Manufactur standard Sbl Folder Gluer - EF-2800 PCW High Speed Automatic Folder Gluer – Eureka , The product will supply to all over the world, such as: Panama, America, Armenia, Actually need to any of those objects be of interest to you, make sure you allow us to know. We'll be delighted to present you a quotation on receipt of one's comprehensive specs. We've our individual specialist R&D enginners to meet any of the requriements, We look forward to receiving your enquires soon and hope to have the chance to work together with you inside the future. Welcome to take a look at our organization.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.