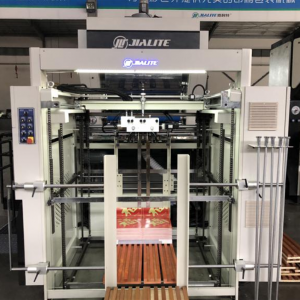

NFM-H1080 Automatic Vertical Laminating Machine

| Model | FM-H |

| FM-1080-Max. paper size-mm | 1080×1100 |

| FM-1080-Min. paper size-mm | 360×290 |

| Speed-m/min | 10-90 |

| Paper thickness-g/m2 (round knife slitting) | 80-500 |

| Paper thickness-g/m2 (hot knife slitting) | ≥115gms |

| Overlap precision-mm | ≤±2 |

| Film thickness (common micrometer) | 10/12/15 |

| Common glue thickness-g/m2 | 4-10 |

| Pre-gluing film thickness-g/m2 | 1005,1006,1206 |

| Non-stop Feeding height-mm | 1150 |

| Collector paper height (incl. pallet)-mm | 1050 |

|

Power |

380V-50Hz-3Pheating power:20Kwworking power:35-45KwTotal power stand by:75Kw

Circuit breaker:160A |

| working pressure-Mpa | 15 |

|

Vacuum pump |

80psiPower: 3kw |

|

Air compressor |

Volume flow:1.0m3/min,Rated pressure:0.8mpaPower:5.5kwIntake pipe Dia. 8mm

(suggest use the Centralized air source) |

| Cable thickness-mm2 | 25 |

| Weight | 9800kgs |

| Dimension (layout) | 8400*2630*3000mm |

| Loading | 40HQ |

FEEDING UNIT

1. Servo Motor Feeder, 4 suckers for lifting and 4 suckers for conveying structure. Max Speed 12000 sheets/h.

2. The paper feeding table has upper and lower over-limit protection.

3. The height of non-stop feeding can reach 1150mm, pre-stacking device, non-stop feeding.

4. Intelligent adjustment of front and rear positions of Feeder, just input product data on the control panel

5. BECKER VACUUM PUMP

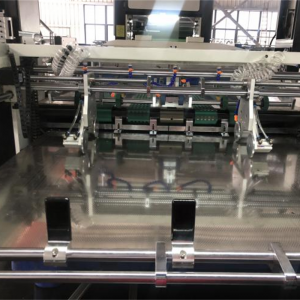

CONVEYING TABLE AND OVERLAP

1.The conveying table adopts customized stainless steel corrugated board.

2.The brush wheel and rubber pressing wheel move smoothly.

3.Servo motor overlap, improve accuracy of lap, error≤±2mm.

DUST REMOVER AND WINDOW LAMINATING(OPTIONAL) Podwer remover window coator and dryer

Single heating roller powder remover device (optional) has a compact structure, the platform has a suction function to ensure that the paper through powder removal device does not shift.

Dust remover can remove the dust on the surface of the paper after printing to avoid white spots after the paper is coated.

According customer demand install inkjet device on dust remover table, inkjet and laminating machine is realized by one machine.

Inkjet table can also be selected independently.

Window coating (optional), composed of gluing machine head and infrared oven. After the paper is glued, it is bonded to the film after passing through an infrared oven.

Drying unit with 12 pcs IR light, Total heating power 14.4kw.

When not using window products, this part can be used as a water powder removing device.

LAMINATOR HOST

Drying roller diameter increased to 1000mm, using electromagnetic heating system.

The heating press roller adopts a segmented heating system, efficient and energy-saving.

Max pressure of press roller is 12T.

Glue roller and metering roller are driven by dual independent motors, making adjustment more convenient.

Gluing system Teflon process treatment, easy to clean and non-sticky.

Waste film winding device.

CUTTING UNIT

The paper cutter is equipped with a tension controller and an anti-curl device to ensure that the paper is flat and not curled.

The paper cutting part contains grinding wheel, disc knife and hot knife for slitting, meeting customers' requirements for slitting films of different materials.

The bounce roller is controlled by an independent motor, and the paper can be separated by using the speed difference.

Hot knife low pressure direct heating and slitting without tail film, detecting paper thickness and slitting, accurate and efficient.

NON-STOP COLLECTOR

The non-stop collector height can reach 1050mm. When the stack is almost full, the delivery conveyor belt will automatically extend to accept the paper. The collector platform will drop. After the tray is replaced, the platform will recycle and complete the non-stop collector.

Adopt pneumatic paper sorting structure to ensure the neatness of the paper and facilitate the next process, with a reduction wheel to prevent the paper from being damaged due to too fast hitting the baffle.

Counting electric eye, the number of running paper is displayed on the display screen at the take-up machine, which can be cleared and accumulated.

Induction electric eye, sensing the length of the paper, if the length of the paper changes, the belt will accelerate, and the baffle of the take-up machine will overturn and lift the paper.

Film lifter

Spare parts