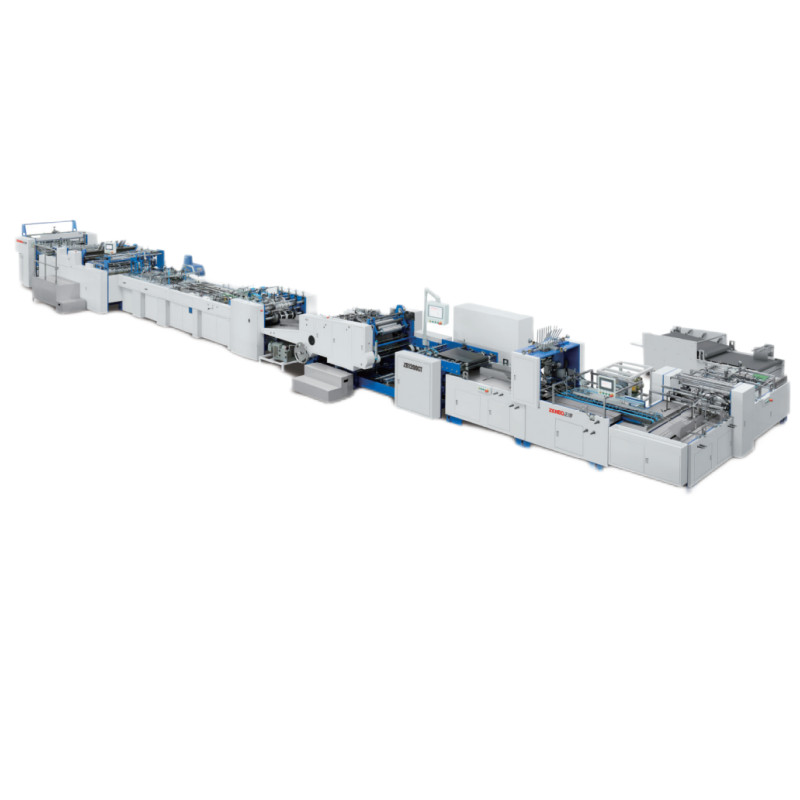

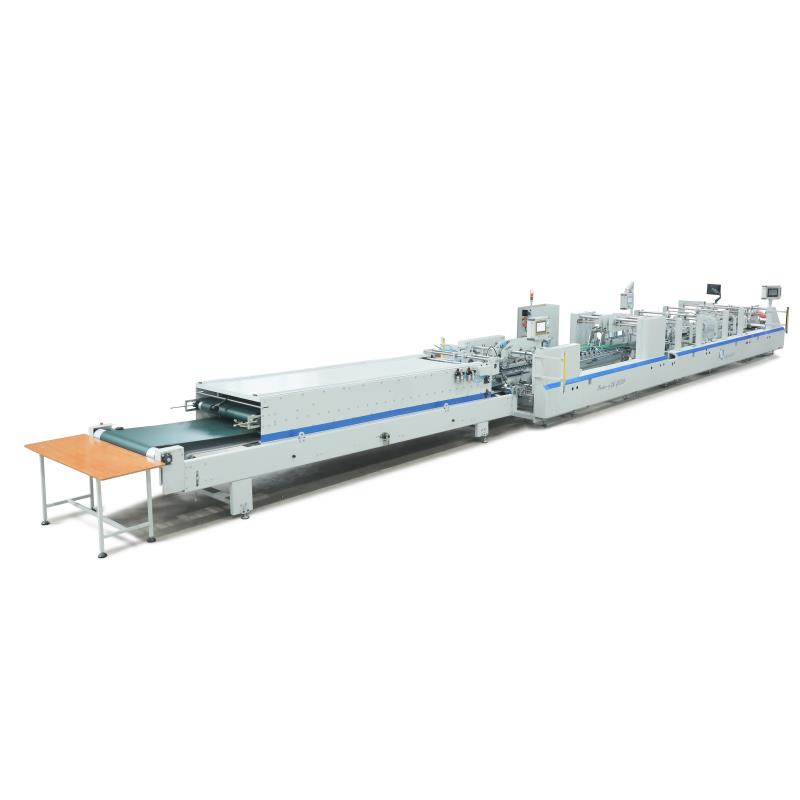

OEM/ODM China Gluer Machine - EF-650/850/1100 Automatic Folder Gluer – Eureka

OEM/ODM China Gluer Machine - EF-650/850/1100 Automatic Folder Gluer – Eureka Detail:

|

EF-650 |

EF-850 |

EF-1100 |

|

|

Maximum Paperboard Size |

650X700mm |

850X900mm |

1100X900mm |

|

Minimum Paperboard Size |

100X50mm |

100X50mm |

100X50mm |

|

Applicable Paperboard |

Paperboard 250g-800g; Corrugated paper F, E |

||

|

Maximum Belt Speed |

450m/min |

450m/min |

450m/min |

|

Machine Length |

16800mm |

16800mm |

16800mm |

|

Machine Width |

1350mm |

1500mm |

1800mm |

|

Machine Heigth |

1450mm |

1450mm |

1450mm |

|

Total Power |

18.5KW |

18.5KW |

18.5KW |

|

Maximum Displacement |

0.7m³/min |

0.7m³/min |

0.7m³/min |

|

Total Weight |

5500kg |

6000kg |

6500kg |

| Configuration |

Units |

Standard |

Optional |

|

|

1 |

Feeder section |

|

√ |

|

|

2 |

Side register section |

|

√ |

|

|

3 |

Pre-folding section |

|

√ |

|

|

4 |

Crash lock bottom section |

|

√ |

|

|

5 |

Lower gluing unit left side |

|

√ |

|

|

6 |

Lower gluing unit right side |

|

√ |

|

|

7 |

Grinder device with dust extractor |

|

√ |

|

|

8 |

HHS 3 Guns cold glue system |

|

|

√ |

|

9 |

Folding and closing section |

|

√ |

|

|

10 |

Motorized adjustment |

|

|

|

|

11 |

Pneumatic Press section |

|

|

|

|

12 |

4 & 6-corner device |

|

|

|

|

13 |

Servo Driven Trombone unit |

|

√ |

|

|

14 |

Lock bottom squaring device at conveyor |

|

|

√ |

|

15 |

Pneumatic square device at conveyor |

|

|

|

|

16 |

Mini-box device |

|

|

|

|

17 |

LED display production |

|

|

|

|

18 |

Vacuum feeder |

|

√ |

|

|

19 |

Ejection channel on trombone |

|

|

|

|

20 |

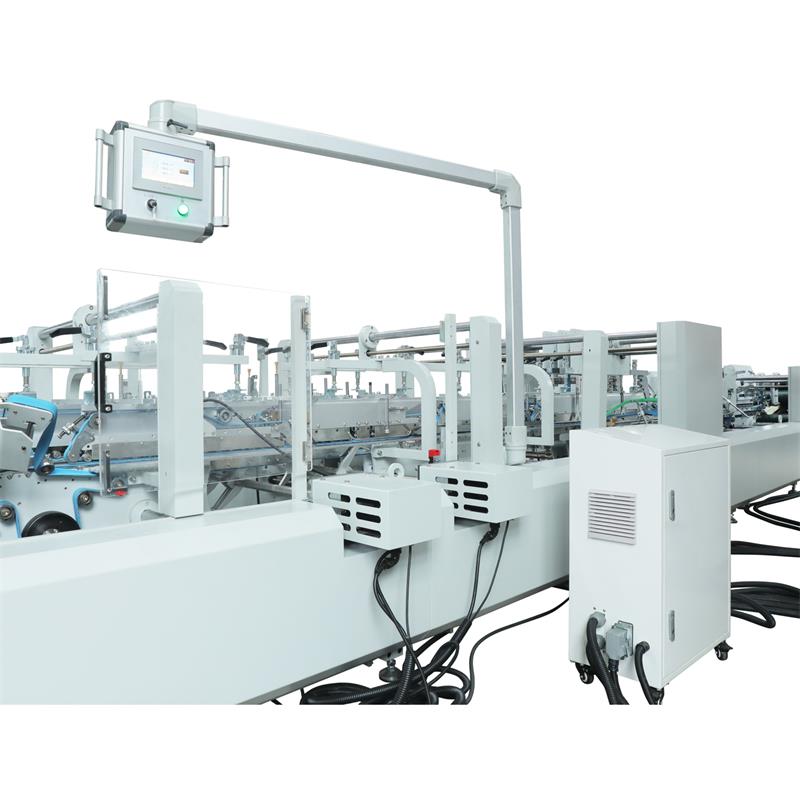

Main touch screen with graphic design interface |

|

√ |

|

|

21 |

Extra feeder and carrier belt |

|

|

|

|

22 |

Remote Control and Diagnose |

|

√ |

|

|

23 |

Plasma system with 3 guns |

|

|

√ |

| 24 | Memory function to save repetitive jobs |

|

||

| 25 | Non-hook crash bottom device |

|

||

| 26 | Light barrier and safety device |

√ |

||

| 27 | 90 degree turning device |

√ |

||

| 28 | Adhesive tape attach |

√ |

||

| 29 | Pressing bearing roller from Japan NSK | √ |

|

|

| 30 | KQ 3 glue system with high pressure pump |

√ |

1) Feeder Section

Feeder section has an independent motor drive system and keep synchronization with main machine.

7 pcs of 30mm feeding belt and 10mm metal plate to move laterally to set width.

The embossed roller guides the feeding belt. Two side apron match the products design.

Feeder section is equipped with three out-feeding blade to adjust according to the product sample.

Vibration device keep paper feeding quickly, easily, continuously and automatically.

Feeder section with 400mm height and brush roller anti-dust device ensure smooth paper feeding.

The operator can operate feeding switch in any area of machine.

Feeder belt can be equipped with sucking function(Option).

Independent monitor can inspect the performance at the tail of the machine.

2)Side register unit

The paper from feeding unit can be rectified at side register unit to ensure accurate feeding.

The driven pressure can be adjusted up and down to fit with different thickness of board.

3)Pre-fold section

The special design can pre-fold the first folding line at 180 degrees and the third line at 165 degrees that can makes box easier to open. 4 corner folding system with intelligent servo-motor technology. It allows accurate folding of all back flaps by means of hooks installed in two independent shafts controlled electronically.

4) Crash lock bottom section

Lock-bottom folding with flexible design and rapid operation.

Crash-bottom can be finished together with 4 set of kits.

20 mm outer belts and 30mm bottom belts. Outer belts platecan be adjusted up and down to fit with different thickness of board by cam system.

5) Lower glue unit

Left and right glue unit are equipped with 2 or 4mm glue wheel available.

6) Folding and closing section

The second line is 180 degrees and the fourth line is 180 degrees.

The special design of the transmission fold belt speed can be adjusted individually to correct box running direction to keep it straight.

7) Motorized Adjustment

Motorized adjustment can be equipped to achieve folding plate adjustment.

8) Pneumatic Press section

Upper section can be moved back and forward depending of box length.

Pneumatic pressure adjustment to keep uniform pressure.

Special extra sponge can be applied to press concave parts.

In auto-mode, the speed of press section keep synchrony with main machine to rise consistency of production.

9) 4 & 6-corner device

Yasakawa servo system with motion module ensure high speed response to match high speed request. Independent touch screen facilitate the adjustment and make operation more flexible.

10)Servo Driven Trombone unit

Adopt photocell counting system with either “kicker” paper automatically or spray ink.

Jam inspection machine.

Up belt running with active transmission.

Whole unit is driven by independent servo motor for adjustment of box interval as wish.

11)Lock bottom squaring device at conveyor

Square device can ensure the corrugated box square well with motorized convey belt height adjustment.

12)Pneumatic square device at conveyor

Pneumatic square device with two carrier at conveyor can ensure carton box with wide but shallow shape to get perfect square.

13) Minibox device

Main touch screen with graphic design interface for convenient operation.

14)Main touch screen with graphic design interface

Main touch screen with graphic design interface for convenient operation.

15)Memory function to save repetitive jobs

Up to 17 sets of servo motor memorize and orient the size of each plate.

Independent touch screen facilitate to set the machine into the certain size against each saved order.

16)NON-hook crash bottom device

With special design slope, bottom of box can be crashed at high speed without conventional hook.

17)Light barrier and safety device

Full mechanical cover get rid of all possibility of injury.

Leuze light barrier, latch type door switch as well as safety relay fulfil CE request with redundant circuit design .

18)Pressing bearing roller from Japan NSK

Complete NKS bearing as press roller machine machine run smooth with low noise and long duration.

|

Outsource list |

|||

| Name | Brand | origin | |

|

1 |

Main Motor | Dong Yuan | Taiwan |

|

2 |

Inverter | V&T | Joint-ventured in China |

|

3 |

Man-Machine interface | Panel Master | Taiwan |

|

4 |

synchronous belt | OPTI | Germany |

|

5 |

V-Ribbed Belt | Hutchinson | Franch |

|

6 |

Bearing | NSK、SKF | Japan/Germany |

|

7 |

Main shaft | Taiwan | |

|

8 |

Plan belt | NITTA | Japan |

|

9 |

PLC | Fatek | Taiwan |

|

10 |

Electrical components | Schneider | Germany |

|

11 |

Pneumatic | AIRTEK | Taiwan |

|

12 |

Electrical detection | SUNX | Japan |

|

13 |

Linear guider | SHAC | Taiwan |

|

14 |

Servo system | Sanyo | Japan |

The machine takes the multi-groove belt transmission structure which can make low noise, stable operation and easy maintenance.

The machine uses frequency converter to achieve automatic control and save power.

The operation equipped with single tooth bar adjustment is easy and convenient. Electrical adjustment is standard.

Feeding belt adopt several extra thick belt equipped with vibration motor to ensure continuous, accurate and automatic feeding.

Because of the sectional plate of up belt with special design, the belt tension can be adjusted automatically according to products instead of manually.

The special structure design of up plate not only can protect the elastic drive effectively but also can avoid damage due to improper operation.

Lower gluing tank with screw adjustment for convenient operation.

Adopt touch screen and PLC control system with remote control. Equipped with photocell counting and auto kicker marking system.

Press section adopts special material with pneumatic pressure control. Equipped with sponge belt to ensure perfect products.

All the operation can be done by hexagonal key tools.

Machine can produce straight-line boxes with pre-folding of 1st and 3rd creases, double wall and crash-lock bottom

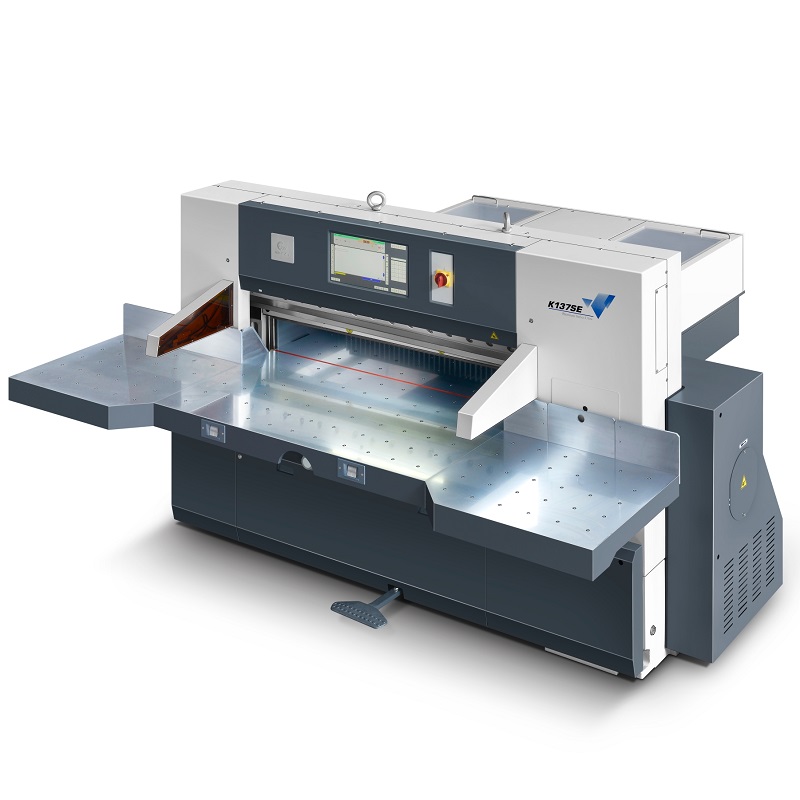

Through the co-operation with top-level partner in the world, Guowang Group (GW) owns Joint venture company with Germany partner and KOMORI global OEM project. Based on the German and Japanese advanced technology and more than 25 years experience, GW continually offer the best and highest efficient post-press solution.

GW adopts the advanced production solution and 5S management standard, from R&D, purchase, machining, assembling and inspection, every process strictly follow the highest standard.

GW invest a lot in the CNC, import DMG, INNSE- BERADI, PAMA, STARRAG, TOSHIBA, OKUMA, MAZAK, MITSUBISHI etc. from all over the world. Only because pursues the high quality. The strong CNC team is the firm guaranty of the quality of your products. In GW, you will feel the “high efficient and high precision”

Product detail pictures:

Related Product Guide:

It can be a great way to enhance our solutions and service. Our mission would be to build inventive products to consumers with a superior working experience for OEM/ODM China Gluer Machine - EF-650/850/1100 Automatic Folder Gluer – Eureka , The product will supply to all over the world, such as: Botswana, Swiss, Wellington, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!