Products

-

Conventional Oven

Conventional Oven is the indispensable in the coating line to work with a coating machine for base coating preprint and varnish postprint. It is also an alternative in the printing line with conventional inks.

-

UV Oven

Drying system is applied in the last cycle of metal decoration, curing printing inks and drying lacquers, varnishes.

-

ETS Series Automatic Stop Cylinder Screen Printing Machine

ETS Full auto stop cylinder screen press absorb sophisticated technology with advanced design and production. It can not only make spot UV but also run monochrome and multi-color registration printing.

-

EWS Swing cylinder Screen Printing Machine

Model EWS780 EWS1060 EWS1650 Max. paper size (mm) 780*540 1060*740 1700*1350 Min. paper size (mm) 350*270 500*350 750*500 Max. printing area (mm) 780*520 1020*720 1650*1200 Paper thickness (g/㎡) 90-350 120-350 160-320 Printing speed (p/h) 500-3300 500-3000 600-2000 Screen frame size (mm) 940*940 1280*1140 1920*1630 Total power (kw) 7.8 8.2 18 Total weight (kg) 3800 4500 5800 Exterior Dimension (mm) 3100*2020*1270 3600*2350*1320 7250*2650*1700 ♦ This dryer is wide... -

EUV-1450/1450 pro High Speed UV Spot And Overall Coating Machine

Max. Sheet Size: 1100*1450mm

Min.Sheet size 350*460mm

Sheet thickness: 128-600gsm

Max coating speed: 6000sph, or 8000sph(pro)

2 IR and 1 UV dryer

Anilox roller and accurate register system for spot and overall UV coating

-

EF series large format (1200-3200) Automatic Folder Gluer

STANDARD MOTORIZED PLATE ADJUSTMENT FOR FAST JOB CHANGING

2-SIDE ADJUSTABLE BELT SYSTEM TO AVOID FISH-TAIL

SIZE AVAILABLE: 1200-3200mm

MAX. SPEED 240M/MIN

20MM FRAME BOTH SIDE FOR STABLE RUNING

-

EUV-1060 High Speed Spot UV Coating Machine

High speed Spot and Over all UV coating machine

2 IR and 1 UV dryer

CE safety standard

Max.Sheet size: 1060mm×730mm

Min. Sheet Size: 406mm×310mm

Max. Coating Speed: 9000sph

Sheet Thickness: 80~500gsm

-

Automatic round rope paper handle pasting machine

This machine is mainly supporting semi-automatic paper bag machines. It can produce the round rope handle on line ,and stick the handle on the bag on line too, which can be attached onto the paper bag without handles in further production and make it into paper handbags.

-

EUD-450 Paper bag rope insertion machine

Automatic paper/cotton rope inserting with plastic ends for high quality paper bag.

Process: Automatic bag feeding, non-stop bag reloading, rope wrapping plastic sheet, automatic rope insertion, counting and receiving bags.

-

EUR Series Fully Automatic Roll-feeding Paper Bag Machine

Fully automatic roll feeding paper bag making with twist rope handle making and sticking. This machine adopts PLC and motion controller, servo control system as well as intelligent operation interface to realize high speed production and high efficiency. With Handle 110bags/min, without handle 150bags/min.

-

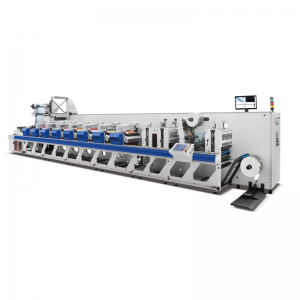

ZJR-450G LABEL FLEXO PRINTING MACHINE

7 colors flexo printing machine for label.

There are 17 servo motors in total for 7 colors machine which ensure the accurate registration running at high speed.

Paper and adhesive paper: 20 to 500 Grams

Bopp , Opp , PET ,PP, Shink Sleeve, IML , Etc, Most Plastic film. (12 micron -500micron )

-

YT-360 Roll feed Square Bottom Bag Making Machine with Inline Flexo Printing

1.With original Germany SIMENS KTP1200 human-computer touch screen, it is easy to operate and control.

2.Germany SIMENS S7-1500T motion controller, integrated with profinet optical fiber,ensure the machine with high speed steadily.

3.Germany SIMENS servo motor integrated with original Japan Panasonic photo sensor, continuously correcting slightest of the printed paper accurately.

4.Hydraulic up and down web lifter structure, integrated with constant tension control unwinding system.

5.Automatic Italy SELECTRA Web guider as standard, continuously correcting slightest alignment variations fast.