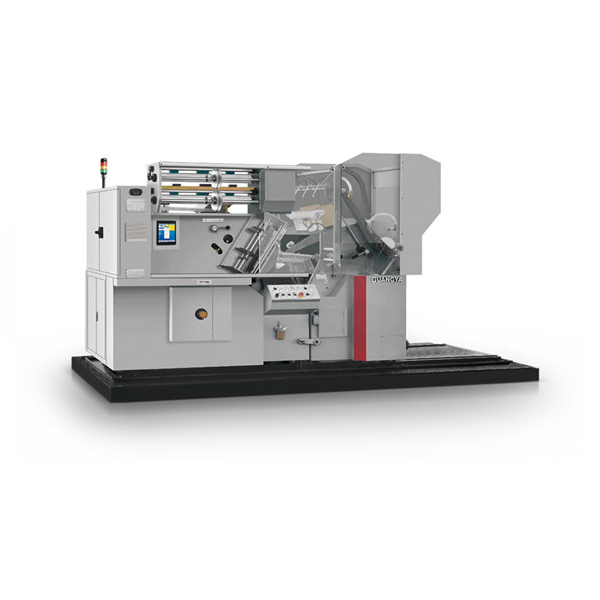

Professional China A4 Cut Size Sheeter - CHM 1400/1700/1900 SHEETER CUTTER – Eureka

Professional China A4 Cut Size Sheeter - CHM 1400/1700/1900 SHEETER CUTTER – Eureka Detail:

CHM precision high speed sheet cutter was widely used for cutting paper, like craft paper, writing paper, art paper, laser paper, aluminum foil paper and board. CHM machine absorb euro and Taiwan technology, adopt servo motor driving, easy operate by touching screen, which those features makes our machine high precision and high speed and became famous brand of the market.

| Model | CHM 1400/1700/1900 SHEETER CUTTER |

| Cutting type | Top rotary knife, bottom knife fixed |

| Reference weight of cutting-paper | 60-550 GSM |

| Cutting accuracy | ±0.5mm |

| Max. Cutting speed | 300sheets/min |

| Max. Cutting meter speed | 300m/min |

| Cutting length range | 450-1450mm |

| Max. Scroll diameter | Max. 1800mm (71’’) |

| Paper-pilling height | 1300mm |

| Max. paper-cutting width | 1400mm/1700mm/1900mm |

| Gross weight | 12000kg/13000kg/14000kg |

Option: Cursor tracking available for MAXCUT 1400/1700/1900 can make cutting accuracy up to ±0.3mm

| Standard Configuration | |

| 1 | Dual position shaftless pivoting arm unwind stand |

| 2 | Air cooling pneumatical disc brake |

| 3 | Manual decurler |

| 4 | Helical knife driven by servo motor |

| 5 | Three sets of slitter for trimming and middle slitting |

| 6 | Anti-Static Bar |

| 7 | Out feed and overlapping section |

| 8 | Hydraulic delivery unit |

| 9 | Auto counting and tap inserter |

| 10 | Siemens touch screen |

| 11 | Siemens PLC. Yasakawa inverter. Imported electrical components |

| Option | |

| 1 | Pneumatic Slitters |

| 2 | Auto tension with load cell |

| 3 | Auto tension based on reel diameter |

| 4 | EPC web guiding |

| 5 | Mechanical-expanding chuck |

| 6 | Motorized decurler |

| 7 | Auto square adjustment |

| 8 | Delivery top belt |

| 9 | Dust removal |

| 10 | Exit roller with air jet |

| 11 | High pile delivery unit |

| 12 | Non-stop stacker |

| 13 | Redundant safety control and interlock system |

| 14 | Auto splicer |

Dual position shaftless pivoting arm unwind stand

Dual position shaftless pivoting arm unwind stand with in-floor track and trolley system.

Air cooling disc brake

Air cooled pneumatical controlled disc brakes on each arm.

Manual decurler

Manual decurler system make the paper plane effectively especially when it approaches core especially for thick board.

Helical Knife driven by servo motor

Length of cut value is numerically enter for quick and easy size changing by 9 inch siemens touch screen

The knife cylinder body is processing precisely after steel welding and makes dynamic balance, vibration and noise during high speed running is reduced effectively.

The blade is made of specially alloy steel SKH.9 with long life and easy maintenance.

Three sets of slitter for trimming and middle slitting

Out feed and overlapping section bar

Fully synchronized speed between high speed out-feeding and overlap tape section to maintain a proper shingle.

Overlapping unit with adjustable overlapping value and jam-stop sensor. Single sheet can be set.

Anti-Static Bar

Hydraulic delivery unit

Siemens touch screen

Length of cut, quantity, machine speed, cut speed can be displayed and set via touch screen.

Auto counting and tap inserter

Siemens PLC, Yasakawa inverter, imported electrical components

Pneumatic slitters:

Heavy duty pneumatic slitters ensure stable and clean slitting.

EPC web guiding

EPC sensor coupled with an independent swing frame allows for minimum edge trim of the web, and strict control of the web edge throughout the reel from start to finish.

Mechanical-expanding chuck

Motorized decurler

Motor driven decurler with remote push button control.

Exit roller with air jet

Exit roller to the delivery unit with air jets to supply a curtain of air onto the underside of the sheets and assist delivery of the sheet into the pile.

Auto square adjustment

According to the cutting length, the squareness of machine will be calculated and oriented automatically.

Auto tension based on reel diameter

Product detail pictures:

Related Product Guide:

With a positive and progressive attitude to customer's interest, our enterprise continually improves our products excellent to meet the wants of customers and further focuses on safety, reliability, environmental requirements, and innovation of Professional China A4 Cut Size Sheeter - CHM 1400/1700/1900 SHEETER CUTTER – Eureka , The product will supply to all over the world, such as: Jamaica, Serbia, Kuwait, They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a should for you of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we are going to possess a vibrant prospect and to be distributed all over the world within the years to come.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.