Roll Feed Bag Making

-

EUR Series Fully Automatic Roll-feeding Paper Bag Machine

Fully automatic roll feeding paper bag making with twist rope handle making and sticking. This machine adopts PLC and motion controller, servo control system as well as intelligent operation interface to realize high speed production and high efficiency. With Handle 110bags/min, without handle 150bags/min.

-

YT-360 Roll feed Square Bottom Bag Making Machine with Inline Flexo Printing

1.With original Germany SIMENS KTP1200 human-computer touch screen, it is easy to operate and control.

2.Germany SIMENS S7-1500T motion controller, integrated with profinet optical fiber,ensure the machine with high speed steadily.

3.Germany SIMENS servo motor integrated with original Japan Panasonic photo sensor, continuously correcting slightest of the printed paper accurately.

4.Hydraulic up and down web lifter structure, integrated with constant tension control unwinding system.

5.Automatic Italy SELECTRA Web guider as standard, continuously correcting slightest alignment variations fast.

-

RKJD-350/250 Automatic V-Bottom Paper Bag Machine

Paper bag width:70-250mm/70-350mm

Max. Speed: 220-700pcs/min

Automatic paper bag machine for producing various sizes of V-bottom paper bags, bags with window, food bags, dried fruit bags and other environmentally friendly paper bags.

-

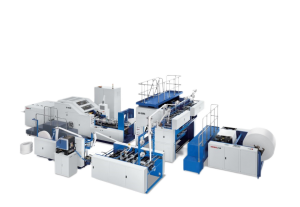

Fully Automatic Roll Feeding Paper Bag Making Machine ZB460RS

Paper Roll Width 670–1470mm

Max.Paper Roll Diameter φ1200mm

Core Diameter φ76mm(3″)

Paper Thickness 90–170g/㎡

Bag Body Width 240-460mm

Paper Tube Length(cutt off length) 260-710mm

Bag Bottom Size 80-260mm

-

YT-220/360/450 SQUARE BOTTOM PAPER BAG MACHINE

1.With original Germany SIMENS KTP1200 human-computer touch screen, it is easy to operate and control.

2.Germany SIMENS S7-1500T motion controller, integrated with profinet optical fiber,ensure the machine with high speed steadily.

3.Germany SIMENS servo motor integrated with original Japan Panasonic photo sensor, continuously correcting slightest of the printed paper accurately.

4.Hydraulic up and down web lifter structure, integrated with constant tension control unwinding system.

5.Automatic Italy SELECTRA Web guider as standard, continuously correcting slightest alignment variations fast.