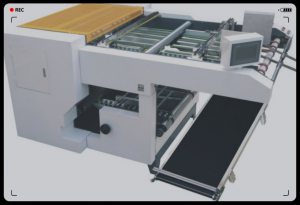

SLG-850-850L corner cutter &grooving machine

SLG-850/850L is multi function automatic corner cutter and grooving machine, it can remove the 4 corners automatically, which instead of die cutter machine.

Saili company is the first & only designer and manufacturer in China. You can not find the similar machine from another supplier.

It widely used for making gift box, shoe box, shoe box,jewelry box, luxury box, rigid box, tea box, wine box . Hard cover and another kinds of box. etc.

Features:

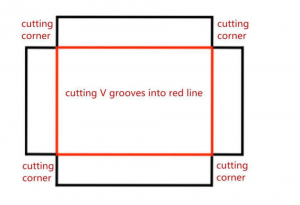

1.Two function in one machine: corner cutting +grooving automatically

2. Remove 4 corner automatically which is instead of die cutter function of corner

3.Automatic feeding by conveyor belt.

4.Through PLC to input the cutting length which you want.

5.With stable chassis, ensure machine to run smoothly and quickly.

6.Durable blade, equipped with blade sharper which makes operation easier.

7.If you don't need the cutting function, you can close it, and only use the grooving

8. High precision and high speed for cardboard

| Model | SLG-850 SLG-850L |

| Material max size: | 550x800mm(L*W) 650X1050mm |

| Material min size: | 130x130mm 130X130mm |

| Thickness: | 1mm---4mm |

| Grooving Normal Accuracy: | ±0.1mm |

| Grooving Best Accuracy: | ±0.05mm |

| Corner Cutting min length: | 13mm |

| Speed: | 100-110pcs/min with 1 feeder |

| Groove degree: | 80°-135° adjustable |

| Groove distance between (blades from same girder): | Min 70 mm |

| Min distance between V shape: | 0:0(no limited)between blades from different girder |

| Cutting knife quantity: | 4 pcs cutting knives in 2 feeder |

| Power: | 4.0kw |

| Max grooving lines: | 9 grooving lines max |

| Knife holder standard : | total 9 sets knife holder(5set of 90º +4 set of 120º) |

| Machine size: | 2400x1532x1400mm(SLG-850L:3600x1832x1400mm) |

| Certificate: | CE |

| Weight: | 1600 KGS 2100 KGS |

| Voltage: | 380V/3 phase/50HZ |

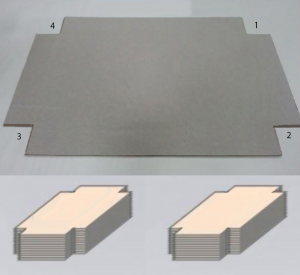

This model is equipped with 90º (5sets x 90º knife holder) and 120º

(4sets x120º knife holder), make V shape, the angel can adjust from 80º to 130º, usually 90º knife holder is used for making 80º--100º V shape, and 120º knife holder is used for making 110º-130º V shape.

About machine what can do?

| Roller material: | Shanghai BAOSTEEL |

| Frequency changer: | Hope brand (If customer need change the brand, we also can use Schneiderbrand or another brand) |

| Low-voltage apparatus: | Eaton Muller brand |

| Machine main motor: | CHENGBANG,TAIWAN BRAND |

| Belt: | XIBEK,CHINA |

| Knife: | Special Tungsten alloy steel |

| Collector belt motor | ZHONGDA brand,China |

| PLC | MCGS TBC7062 |

| Sensor | Omron/Panasonic |

| Inverter | Siemens /Panasonic/Schneider |

Standard Machine parts together with machine for user:

|

Name |

Qty |

|

Grinder of knife |

1ea |

| Tool box((including 1set Allen wrench,straight screwdriver of 4 inch, open spanner,adjustable wrench,grater) |

1pc |

|

Grooving blade |

20pcs |

To put the pile of material on the feeding section, and the belts with the aligning system will automatically send the cardboard into grooving area. The final product will be conveyed out to the collecting table.

Aligning system with rubber roller will correct the belt direction automatically and keep it straightly.

Cutting knife

The cutting length data through PLC to input, the cutting knife is round knife. One feeder with 2 cutting knife, 2 feeder with 4 cutting knives

Automatic Grinder of knife

together with machine

Grooving blade

Blade Life: usually the blade can working 20000-25000pcs after 1 time sharping. And 1pc blade can been sharpened about 25-30 times with good user.

Sample of V shape on board material: