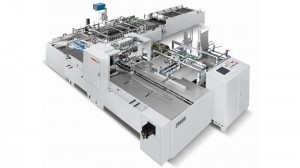

YT-360 Roll feed Square Bottom Bag Making Machine with Inline Flexo Printing

This machine is designed to manufacture square bottom paper bags without handles from paper roll, and it is an ideal equipment for producing small-size bag fast. By implementing steps including paper feeding, tube forming, tube cutting and bottom forming inline, this machine can effectively save labor costs. The equipped photoelectric detector can correct cutting length, so as to ensure cutting precision. The equipped Germany REXROTHPLC system and the mature advance computer design program that ensure the machine perform quickly and stably. The humanize designed collection platform and counting function improve packing efficiency . this machine can make bags of very thin paper, thus it is especially suitable applied in food goods packing.

1.With original Germany SIMENS KTP1200 human-computer touch screen, it is easy to operate and control.

2.Germany SIMENS S7-1500T motion controller, integrated with profinet optical fiber,ensure the machine with high speed steadily.

3.Germany SIMENS servo motor integrated with original Japan Panasonic photo sensor, continuously correcting slightest of the printed paper accurately.

4.Hydraulic up and down web lifter structure, integrated with constant tension control unwinding system.

5.Automatic Italy SELECTRA Web guider as standard, continuously correcting slightest alignment variations fast.

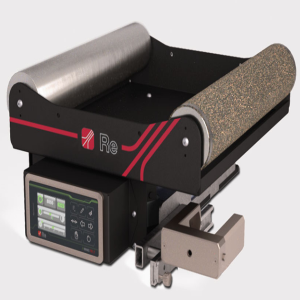

6.This is the webguide mechine made by Re Controlli lndustriali in Italy.During the processing the material must be accurately aligned from unwinding to rewinding,which is very important to improve production efficiency and ensure product quality.RE`s webguide machine is reliable and easy to operate, its actuator uses a stepping motor and ensures fast and accurate.

This is a load cell (tension sensor) from RE Controlli lndustriali in Italy, using to measure any subtle changes accurately in material tension in the material tension automatic control system.

T-one tension controller from RE Controlli industriali in Italy. It`s integrated,embedded, with an industrial plant.

The T-one controller with tension sensors and brake forms a material tension control system,It uses its front panel to control the adjustment parameters and to program and calibrate the instrument itself,which is very easy to use.

The core microprocessor uses P.I.D algorithm to keep the material tension stable at the desired value.

This is the Italian RE pneumatic brake on the unwinder. It forms a material tension automatic control system with a tension controller(e.g T-ONE)and tension sensors.It uses different torgue brake calipers(100%,40%,16%),so that it can be applied to a variety of different working conditions and accurately adjust the tension of the material.

|

Model |

YT-200 | YT-360 | YT-450 |

|

The highest Speed |

250pcs/min | 220pcs/min | 220pcs/min |

|

C Cutting length of paper bag |

195-385mm | 280-530mm | 368-763mm |

|

W Paper bag width |

80-200mm | 150-360mm | 200-450mm |

|

H Paper bag bottom width |

45-105mm | 70-180mm | 90-205mm |

|

Paper thickness |

45-130g/m2 | 50-150g/m2 | 70-160g/m2 |

|

Paper roll width |

295-650mm | 465-1100mm | 615-1310mm |

|

Roll paper diameter |

≤1500mm | ≤1500mm | ≤1500mm |

|

Machine power |

3Phrase 4line 380V 14.5kw | 3Phrase 4line 380V 14.5kw | 3Phrase 4line 380V 14.5kw |

|

Air supply |

≥0.12m³/min 0.6-1.2MP | ≥0.12m³/min 0.6-1.2MP | ≥0.12m³/min 0.6-1.2MP |

|

Machine weight |

8000kg | 8000kg | 8000kg |

|

Back cover method(threekinds) |

In | In | In |

| Servo thumb cutter | In | In | In |

|

Patch and flat knife |

In | In | In |

|

Machine size |

11500x3200x1980mm | 11500x3200x1980mm | 11500x3200x1980mm |

C=L+H/2+(20~25mm)

CONTROL SYSTEM

*1. Germany SIMENS touch screen human-computer interface control system, operating at a glance.

*2. With Germany SIMENS Motion controller (PLC) integrated with 100M optical fiber to control the whole procession.The SIMENS servo driver associates with the power line to take control of the servo motor operation. They unit to ensure the machine with high speed and high precision motion control.

*3. France SCHNEIDER low voltage electric element, surly guarantee the machine with long life and avoid any instability under high speed running.

*4. Fully enclosed dust-free electrical box

UNWINDING SECTION

*5.With hydraulic up and down material lifter, it is easy to change paper roll and lift the paper roll up and down. With auto min roll diameter alarm function, the machine speed down automatic and then stop.

*6. With magnet powder tension system ensure tension control stable and accurate.

*7. With Italy Re ultrasonic edge alignment sensor,it is free from the influence of light and dust condition, to gain a more sensitive and higher precision. It cut off alignment time and decline material waste..

*8. Automatic Italy Re guider as standard, continuously correcting slightest alignment variations fast. The response time is within 0.01s, and precision of 0.01mm.It cut off alignment time and decline material waste.

SIDE GLUING

TUBE FORMING SECTION

*9. With gluing nozzle for side gluing. It is able to adjust the glue outlet, and make the glue straight. It is efficient and economic.

*10. High pressure gluing stove tank for side and bottom glue supplying, it is easy to use and substantially decline the cleaning job and also glue saving glue output speed controlled by the proportional, speed change automatically accordance to the machine running speed.

*11 With original Panasonic photo sensor, continuously correcting slightest of the printed paper accurately. When any mistakes come up, the machine stop automatically. This really help to decline the unqualified product rate.

TRANSMISSION SYSTEM

*12. With high precision transmission gear characteristic with long service life, there is no shaking during running. More precision and faster and more steadily.

*13. With automatic lubricating system makes routine Maintenance very easy. This system will lubricate the whole gear system automatic when the machine is running.

BAG BOTTOM FORMING SECTION

*14. Available Germany SIMENS servo motor to control the length of the paper bag. Cut off the paper tube with a tooth knife or normal knife in a high-speed uniform rotation, ensure the incision even and beautiful.

BAG BOTTOM FORMING SECTION

*15. Bag bottom forming section.

COLLECTION SECTION

*16. Machine come with product counting and quantitative mark function by set on the human-computer interface. It help to collect product, easier and correctly.

|

Name |

QTY |

Original |

Brand |

|||

|

Control System |

||||||

|

Human-computer responsive touch screen |

1 |

France |

SIMENS |

|||

|

PLC Program Motion Controller |

1 |

Germany |

SIMENS |

|||

|

Traction Servo Motor |

1 |

Germany |

SIMENS |

|||

|

Traction Servo Motor driver |

1 |

Germany |

SIMENS |

|||

|

Host Servo Motor |

1 |

Germany |

SIMENS |

|||

|

Host Servo Motor driver |

1 |

Germany |

SIMENS |

|||

|

Photoelectric printing mark tracking sensor |

1 |

Japan |

Panasonic |

|||

|

Low voltage electrical apparatus |

1 |

France |

SCHNEIDER |

|||

|

Photoelectric sensor |

1 |

France |

SCHNEIDER |

|||

|

EPC and Tension Control system |

||||||

|

Weber guider controller |

1 |

Italy |

Re |

|||

|

Weber guider Servo motor |

1 |

Italy |

Re |

|||

|

Transmission system |

||||||

|

Synchronous belt |

1 |

China |

|

|||

|

Synchronous wheel |

1 |

China |

|

|||

|

Bearing |

1 |

Japan |

NSK |

|||

|

Guide roller |

1 |

China |

|

|||

|

gear |

1 |

China |

ZHONGJIN |

|||

|

Paper roll unwinding air shaft |

1 |

China |

Yitai |

|||

|

Finished bag conveyor belt |

1 |

Switzerland |

|

|||

|

Gluing system |

||||||

|

Bottom glue device ( water-based glue) |

1 |

China |

Yitai |

|||

|

high precise adjustable Glue nozzle for middle water-based glue |

1 |

China |

KQ |

|||

|

High pressure glue tank for middle Water-based glue supplying |

1 |

China |

KQ |

|||

|

Forming Section |

||||||

|

Mold for bag tube forming |

5 |

China |

Yitai |

|||

|

Keel |

1 |

China |

Yitai |

|||

|

Round roller |

8 |

China |

Yitai |

|||

|

rubber wheel for pressing paper |

6 |

China |

Yitai |

|||

Notice: *The machine design and specifications are subject to change without prior notice