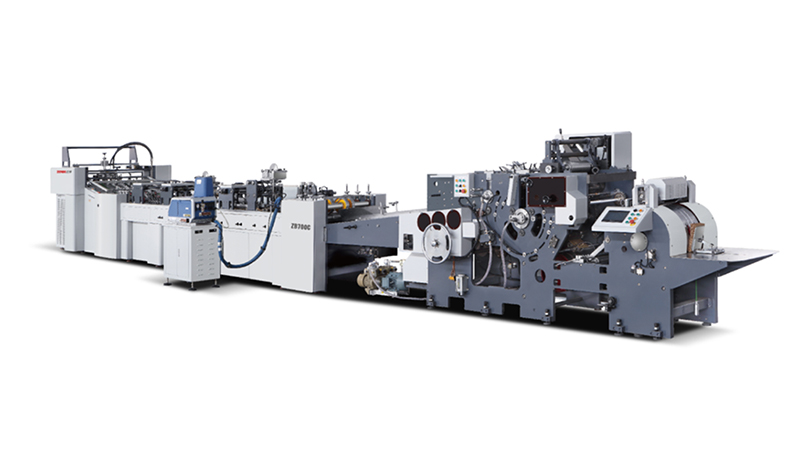

ZB700C-240 sheeting feeding paper bag making machine

ZB700C-240 sheeting feeding paper bag making machine is suitable for the mass bag production,

it is the first choice of medium&top grade handbag device. The product adopts engine, electricity, light,

gas integration technology, setting a number of its proprietary technology, can one time leaflet after the

paper printing, automatic paper feeding, position, die-cutting, tube folding, bottom folding and gluing to compaction output.

The variable speed drive technology, combined with the system of vertical and horizontal creasing,

bottom folding realize trackless bag molding process..

|

|

ZB 700C-240 |

|

| Max.sheet (LX W): | mm | 720 x460mm |

| Min.sheet (LX W): | mm | 325 x 220mm |

| Sheet weight: | gsm | 100 - 190gsm |

| Bag Tube Length | mm | 220– 460mm |

| Bag Width: | mm | 100 - 240mm |

| Bottom Width(Gusset): | mm | 50 - 120mm |

| Bottom type | Square bottom | |

| Machine speed | Pcs/min | 50 - 70 |

| Total /Production power | kw | 20/12KW |

| Total weight | tone | 9 T |

| Glue type | Water base glue and hot melt glue | |

| Machine size (L x W x H) | mm | 13800 x 2200x 1800 mm |

| Main part Origin | |||||||

|

No. |

Name | Origin | Brand |

No. |

Name | Origin | Brand |

|

1 |

Feeder | China | RUN |

8 |

Touch screen | Taiwan | Weinview |

|

2 |

Motor | China | Fangda |

9 |

Belt | Japan | NITTA |

|

3 |

PLC | Japan | Mitsubishi |

10 |

Vacuum pump | Germany | Becker |

|

4 |

Frequency converter | France | Schneider |

11 |

Air cylinder | Taiwan | AIRTAC |

|

5 |

Button | Germany | EATON Moeller |

12 |

Photoelectric switch | Korea/Germany | Autonics/Sick |

|

6 |

Relay | Germany | Weidmuller |

13 |

Hot melt glue system | U.S.A. | Nordson |

|

7 |

Air switch | Germany | EATON Moeller | ||||

Write your message here and send it to us