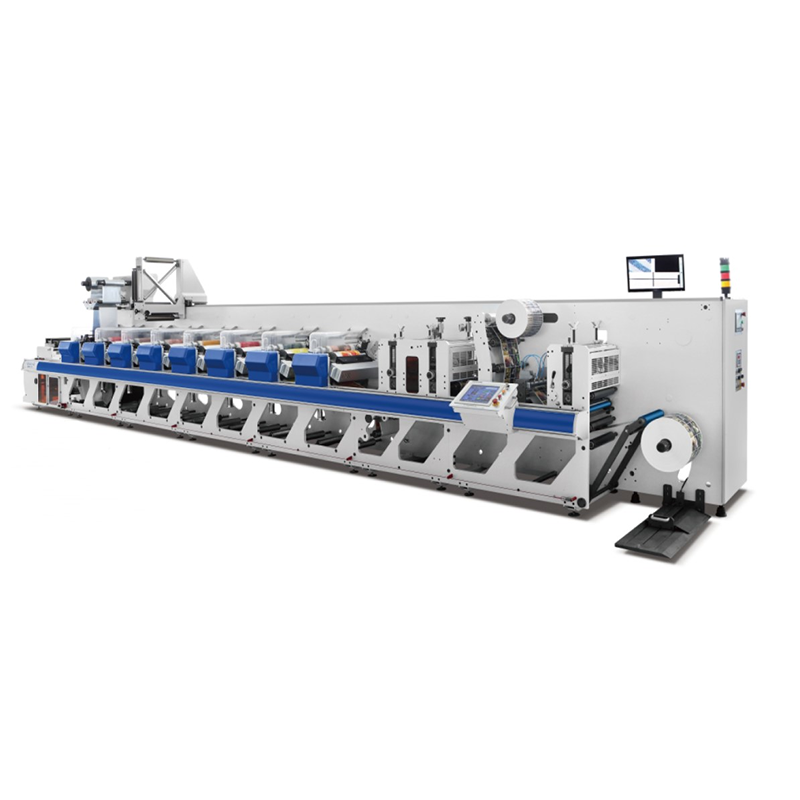

ZJR-450G LABEL FLEXO PRINTING MACHINE

CHARACTERISTIC

1. The whole machine adopts the latest servo control system Siemens from Germany and each printing

Unit is driven by independent servo motor. There are 17 servo motors in total for 7 colors machine which ensure the accurate registration running at high speed.

2. The printing roller adopts sleeve system which is light, easy, convenient and fast to change. This design largely improves the printing quality and reduces the maintenance.

3. Fast and easy pressure adjustment of printing or ink transferring: printing roller run by bearer. It is not

necessary to adjust the pressure when change the roller, or at most fine adjust for special job.

4. Anvil roller equips with water chiller, it’s good for film material as well

MATERIAL SUBSTRATE

Paper and adhesive paper: 20 to 500 Grams

Bopp , Opp , PET ,PP, Shink Sleeve, IML , Etc, Most Plastic film. (12 micron -500micron )

MAIN TECHNICAL SPECIFICATION

|

Model |

ZJR-450G model |

| Max Printing Speed | 180m/min |

| Printing Color | 7 colors |

| Max. Width of Paper | 470mm |

| Max .Printing Width | 450mm |

| Max. Unwinding Diameter | 900mm |

| Max. Rewinding Diameter | 900mm |

| Printing Length | Z76-Z192(241.3mm-609.6mm) |

| Dimensions(8Colors+3Die Cutting) | 10.83m x 1.68m x 1.52m ( L x W x H ) |

MACHINE PICTURES:

3)Movable Turn Bar

4) Movable Touch Screen

5) Matrix Unit (with die cutting unit) + Magnetic Roller Lifter

Machine Configuration :

Auto Control System

-The latest Siemens control system

-Operation in both English and Chinese

-Registration senor (P+F)

-Automatic fault detection and alarm system

-BST Video inspecting system (4000type)

-Power Supply: 380V-400V ,3P , 50HZ-60HZ

Material Feeding System

-Unwinder with pneumatic lift ( Max. diameter :900mm)

-Air shaft (3inches)

-Automatic inflated and deflated

-Pneumatic rotaing joint

-Magnetic powder brake

-Automatic tension control

-Automatic stopping system for lacking of material

-RE web guiding system

-Infeed by servo motor (Siemens servo motor )

Printing System

-Super flexo printing unit

-Printing cylinder is controlled by independent direct driven motor (to avoid the gear marking )

-Printing cylinder with sleeve, is light and easy to change .

-Printing plate : plates mounted on the sleeve

-Free impression roller and water chiller roller .

-Water chiller roller driven by independent servo motor and it can print the plastic film well .

-Automatic cooling circulatory system

-Free impression roller and water chiller is designed in separated , even ink run in the impression roller,it can be easy to clean because without uv curing .

-Each printing unit have two servo motor control .

The Servo 1 controls the Printing sleeve ,and the Servo 2 control the big chiller drum roller .

-Pre-registeration is controlled by servo motor , and the motor will calculate automatically when you input the printing length in the main touch screen . the printing sleeve will go to the corresponding position base on the zero point on the sleeve.

-Fine registeration should be adjusted on the touch screen

When you do the correct color register ,then open the register sensor to read the printing mark and the machine can do automatic registeration always .

-Operation panel for fine adjustment with self-locking function

-Fine pressure adjustment for the bearer

-The pressure among the anilox roller ,printing plate and material will be fine adjusted by bear which

Controlled by small motor . it can be operated easily by attached key .

-Second Pass by registration sensor (P+F)

-Easy take off anilox roller

-Easy tak-off ink tray ,auto up/down

-Movable touch screen ( easy operation)

-Guard line for whole machine ( Schneider-France)

UV Dryer (Fan cooler 9KW per unit)

-UV Ray brand from Italy , Stepless electronic UV

-Independent power control for each UV dryer

-Power auto changing according to printing speed

-Auto control with UV exhaust

-Independent UV control panel

Rewinding System

-Driven by independent servo motor (3 inch air shaft )

-Double rewinder for optional

-Automatic inflated and deflated

-SMC Pneumatic swivel

-RE automatic tension control system

-Rewinder with pneumatic lift ( Max. diameter :900mm)

Main Configuration

|

● CONTROL SYSTEM |

|||

|

Description |

Note |

Quantity |

Brand Name |

| Computer Control System | Multi-Axis Control System |

1 |

Siemens(Germany) |

| PLC |

1 |

Siemens(Germany) |

|

| PLC Extending Module |

1 |

Siemens(Germany) |

|

| Analog Module |

1 |

Siemens(Germany) |

|

| Touch Screen for Main Machine | True Color |

1 |

Siemens(Germany) |

| Remote IO Module |

1 |

Phoenix (Germany) |

|

| Air Switch |

1 |

Schneider (France) |

|

| Switch/ Button |

8 |

Schneider (France) |

|

| Contactor |

5 |

Schneider (France) |

|

| Switching Power Supply |

1 |

Meanwell (Taiwan) |

|

| Aviation Plug & Terminal Block |

6 |

SIBAS |

|

|

● EACH PRINTING UNIT |

|||

|

Description |

Note |

Quantity |

Brand Name |

| Water Chiller Roller Servo Motor |

1 |

Siemens(Germany) |

|

| Water Chiller Roller Servo Motor |

1 |

Siemens(Germany) |

|

| Printing Form Roller Servo Motor |

1 |

Siemens(Germany) |

|

| Printing Form Roller Servo Driven |

1 |

Siemens(Germany) |

|

| Special Decelerator |

1 |

SH1MPO-ABLE(Japan) | |

| Limit Switch |

8 |

Schneider (France) |

|

| Straight Guiding Track |

4 |

PMI (Taiwan) |

|

| Cylinder |

14 |

SMC (Japan) |

|

| href="#/javascript:;" Solenoid Valve |

10 |

SMC (Japan) |

|

|

● WEB-PASSING SYSTEM |

|||

|

Description |

Note |

Quantity |

Brand Name |

| Servo Motor | 3KW |

2 |

Siemens(Germany) |

| Servo Motor Driver |

2 |

Siemens(Germany) |

|

| Special decelerator |

2 |

SH1MPO-ABLE(Japan) |

|

| Photocell for end roll |

1 |

Schneider (France) |

|

|

● REWINDER SYSTEM |

|||

|

Description |

Note |

Quantity |

Brand Name |

| Servo Motor |

1 |

Siemens(Germany) | |

| Sensor |

1 |

RE – Italy | |

| Switch |

Several |

Schneider (France) | |

|

● UNWINDER SYSTEM |

|||

|

Description |

Note |

Quantity |

Brand Name |

| Ultrasonic web guider |

1 |

RE – Italy | |

| Magnetic powder device |

1 |

RE – Italy | |

| Sensor |

1 |

RE – Italy | |

| Switch |

Several |

Schneider (France) | |

|

● OTHER SYSTEM |

|||

|

Description |

Note |

Quantity |

Brand Name |

| UV Dryer System |

|

1SET |

UV Ray-Italy |

| Video System |

|

1SET |

BST (Germany) |

Machine in our workshop:

Our CNC WORKSHOP

Some Printing Samples: