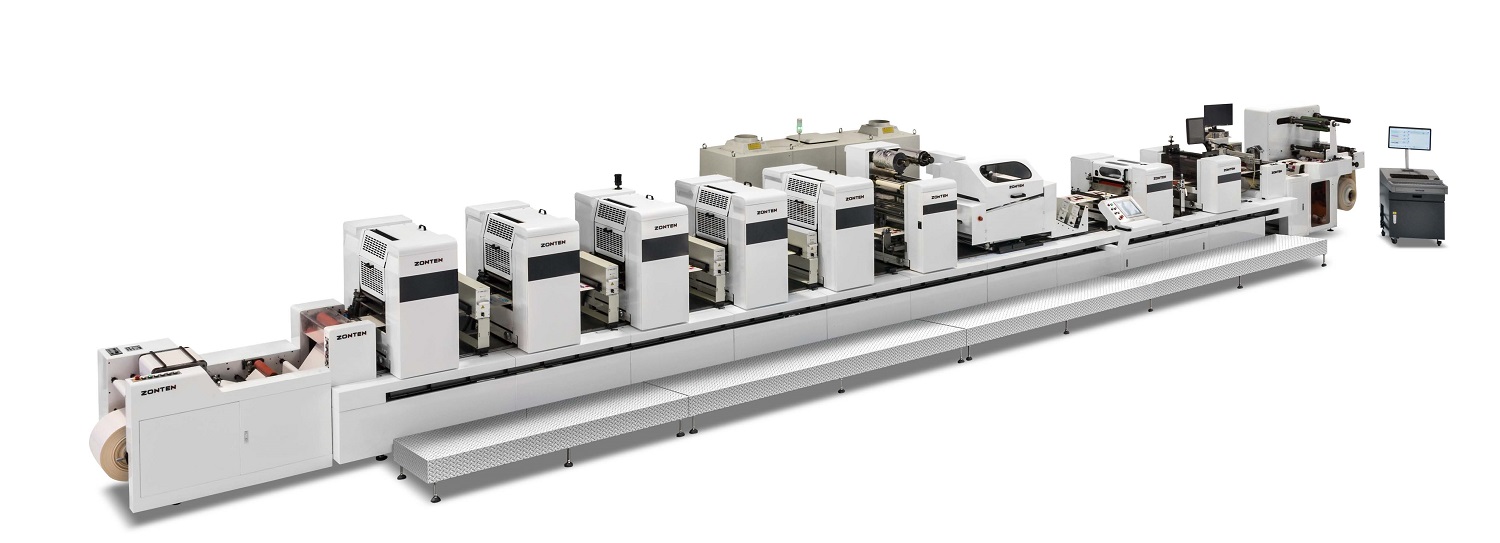

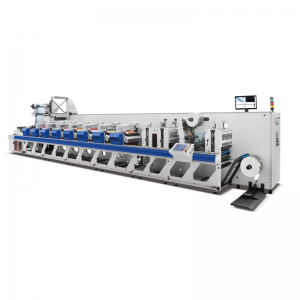

ZTJ-330 Intermittent Offset Label Press

| Max. printing size | 320*350mm |

| Max. Die cutter size | 320*350mm |

| Width of paper | 100-330mm |

| Thickness of substrate | 80-300g/m2 |

| Repeat length | 100-350mm |

| Press speed | 30-180rpm (50m/min) |

| Motor rating | 30kw/6colors |

| Power | 380V, 3phases |

| Pneumatic requirement | 7kg/cm2 |

| Plate | PS Plate |

| PS Plate Thickness | 0.24mm |

| Alcohol | 12%-10% |

| Water | Around 90% |

| Water Temperature | 10℃ |

| Printing Cylinder Diameter | 180mm |

| Rubber Sheeting | 0.95mm |

| Ink Rubber | 23pcs |

| Impression Rubber | 4pcs |

| Max speed | 8000sheets/h |

| Max speed size | 720*1040mm |

| Min sheet size | 390*540mm |

| Max printing area | 710*1040mm |

| Thickness(weight) of paper | 0.10-0.6mm |

| Feeder pile height | 1150mm |

| Delivery pile height | 1100mm |

| Overall power | 45kw |

| Overall dimensions | 9302*3400*2100mm |

| Gross weight | About 12600kg |

|

●CONTROL SYSTEM |

||

|

Description |

Note |

Brand Name |

| Computer control system |

Multi-axis control system |

Trio---------UK |

| Touch screen for main machine |

12inch,multicolor |

Proface-----Japan |

| PLC |

|

Mitsubishi---Japan |

| PLC extending module |

|

Mitsubishi---Japan |

| Frequency converter |

400W |

Mitsubishi---Japan |

| Frequency converter |

750W |

Mitsubishi---Japan |

| Coder |

|

Omron-------Japan |

| Switch、Button |

|

Fuji----------Japan Schneider---France |

| Contactor

|

Simon-----Germany | |

| Analogy module

|

|

Mitsubishi---Japan |

|

Switching power supply |

|

Meanwell----Taiwan |

|

Aviation plug and terminal block |

|

Hangke----Taiwan |

|

●EACH PRINTING UNIT |

||

|

Description |

Note |

Brand name |

| Servo motor | 3KW | Panasonic-----Japan |

| Servo motor driver | Panasonic-----Japan | |

| Speed reducer | APEX----------Taiwan | |

| Frequency converter | Mitsubishi----Japan | |

| Proximity detector | Omron---------Japan | |

| Air cylinder | SMC------------Japan | |

| Straight Guiding | HIWIN-------Taiwan | |

| Track Rapid-travel motor | 200W | Jingyan------Taiwan |

| Speed reducer | Jingyan------Taiwan | |

| Ink rubber | Basch--------Shanghai | |

| Coder | Omron-------Japan | |

| Bearing |

NSK-------Japan |

|

| Limit switch |

Omron----Japan |

|

| Ink roller | BASCH------Shanghai | |

|

●MATERIAL FEEDING SYSTEM 1 |

||

|

Description |

Note |

Brand Name |

| Servo motor |

3KW |

Panasonic-----Japan |

| Servo motor driver | Panasonic-----Japan | |

| Special decelerator | APEX---------Taiwan | |

| Photocell for unwinder | Omron--------Japan | |

| 2nd pass sensor

|

|

Sick----------Germany

|

| Air cylinder

|

SMC--------Japan | |

|

●MATERIAL FEEDING SYSTEM 2 |

||

|

Description |

Note |

Brand Name |

| Motor | 200W | Jingyan----Taiwan |

| Speed reducer | Jingyan----Taiwan | |

| Frequency converter |

200V/0.4KW |

Panasonic-----Japan |

|

●REWINDER SYSTEM |

||

|

Description |

Note |

Brand Name |

| Rewinder motor | L28—750W—7.5S | Chenggang-----Taiwan |

| peripheral pump | China | |

| Frequency converter |

|

Panasonic-----Japan |

| Switch | Schneider (France) | |

| Rewinder sensor | Omron-------Japan | |

|

●WEB-PASSING SYSTEM |

||

|

Description |

Note |

Brand Name |

| Servo motor |

3KW |

Panasonic-----Japan |

| Servo motor driver | Panasonic-----Japan | |

| Speed reducer | APEX--------Taiwan | |

| Air cylinder | SMC----------Japan | |

1) Servo driven: Independent servo driven system in each unit to guarantee stable register at high printing speed.

2) Printing unit: Use the most advanced inking system which has 23 inking rolls, four large diameter form rolls included and alcohol damping system to guarantee printing quality.

3) Pre-register system: Based upon the printing length, log data into the sliding control station, each unit will automatically be adjusted to its ready position.

4) Register system: Each printing unit can remote adjust register which includes lineal, lateral and skewing without stopping the press to save time and reduce the waste of substrate.

5) Vacuum backflow control unwinding: Vacuum backflow cylinder should be able to prevent scratches on the back of P/S label during intermittent motion.

6) Joystickless: Fully automatic operation system including pressure adjustment, inking roll washup, roller impression, etc.

7) Easy to operate: Equipped with sliding touch screen control station which can be moving around to increase the efficiency of operator.

8) Printing size: Pattered technology to minimize printing size to achieve larger scale of variable size printing.

9) Control system: Apply electronic component from famous international brand to guarantee long term reliable operation.

10) Lubrication system: Centralized automatic lubrication.