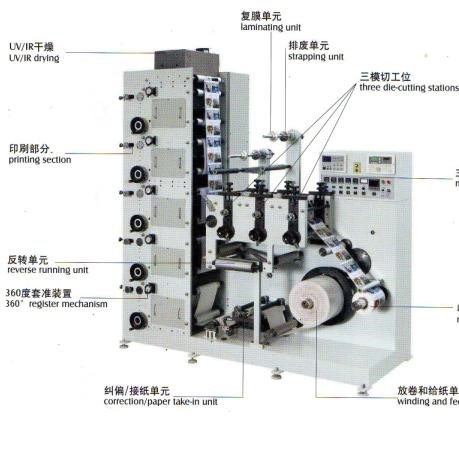

LRY-330 Multi-function Automatic Flexo-Graphic Printing machine

| Material width | 330mm |

| Printing width | 320mm |

| Printing girth | 175-380mm |

| Max. unwind diameter | 650mm |

| Max. rewind diameter | 650mm |

| Printing speed | 10-80m/min |

| Accuracy of registration | ±0.15mm |

| Part name | Qty | Description |

| Printing roller | 3 sets | the size is determined by the user from 57teeth to 120teeth |

| Anilox cylinders | 1 set | the lines can be chosen from 200 to 1000 by the user |

| Mounting machine | 1 set | |

| Turn bar | 1 set | |

| Unwind tension Controller | 1 piece | Mitsubishi of Japan |

| Transducer | 1 pc | Taiwan |

| Rewind tension Controller | 1 piece | made in China |

| Magnetic power Brake | 3 pcs | China |

| Electromagnetism Valve | 2 pcs | Japan |

| Inverter | Taiwan | |

| Stop automatic when paper lack | ||

| Machine stop automatic when the paper broken | ||

| Contactor | Schneider France | |

| Time replay | 1 pc | Taiwan |

| Solid reply | 2 pcs | Japan |

| Temperature Controller | China | |

| All air Switches | Schneider France | |

| Other low-pressure Wiring Schneider | France/ China | |

1. The main motor adopts imported inverter to govern a stepless speed adjustment.

2. Feeding and rewinding are controlled through magnetic particle brake and clutch (Japanese Mitsubishi auto tension controller).

3. Un winder system is controlled by edge guide sensor.

4. Adopt ceramic anilox roller which offers durability, wear resistance and corrosion resistance, also is more efficient on production by reducing the times of changing rollers.

5. The printing units are all equipped with a group of infrared dryers respectively.

6. Each IR dryer device of printing unit is interchangeable to UV dryer.

7. Un winder and re winder adopt air core holder.

8. The printing unit can register in 360 degrees. Each printing unit can be independently geared and loosen to have rest of units continue to printing.

9. The roll feeding, printing, UV vanish, auto infrared drying, laminating and rewinding can be processed in one pass. It has characterized by wide application, fast printing speed and high economic efficiency Ink will not contaminate environment. So it is an idea printing machine for the business form, Tag and high end pressure sensitive label.

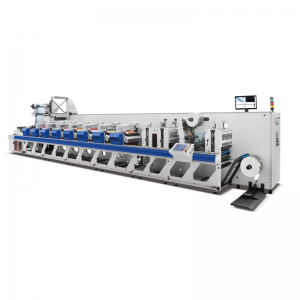

The photo is: LRY-330 Flexo-printing machine:6colors+6UV dryer+6 IR dryer (Taiwan, 4.8KW) + conveyor belt (OPTIONAL)+ CCD camera (BST, Germany, OPTIONAL) + Cold foil (OPTIONAL) + web guide (BST Germany)

This photo is standard ink box, you can change to be Enclosed doctor chamber and ink pump.